After reading this article you will learn about:- 1. Meaning of System 2. Definition of System 3. Classification 4. Design 5. Overall Objectives 6. Advantages.

Meaning of System:

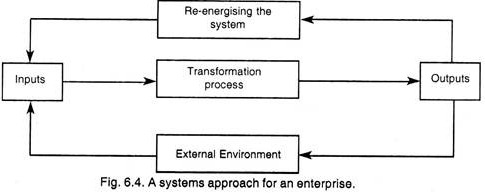

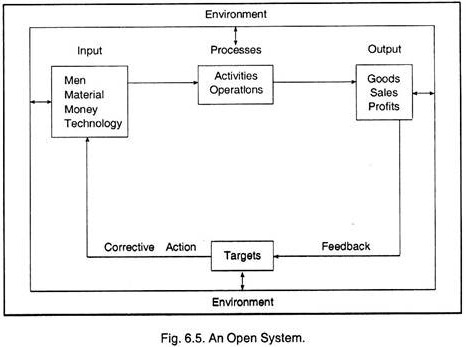

A system can be defined as an orderly arrangement of components like, men, materials, money, machine and environment that are inter-related, and act and interact with one another to perform task or function in a particular environment. A system is composed of elements or sub-systems that are related and dependent on each other.

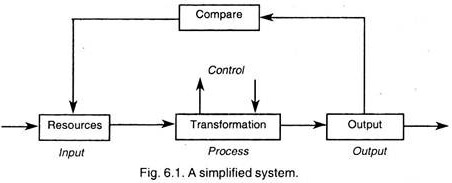

A system can be considered as a structure of sub-systems each having the following characteristics:

(a) Inputs,

(b) Transformation (conversion) process,

(c) Output, and

(d) Feedback.

From the above, we see that every organisation can be represented as a system consisting of interacting sub-systems. The basic process of the system converts the resource input into some useful form of outputs. However, depending upon the efficiency of transformation (conversion) process, we may have undesirable outputs too, like pollution, scrap or wastage, rejection etc.

Any business organisation has finance, marketing, accounting, personnel, engineering, purchasing, and distribution systems besides operations system.

For understanding the meaning of system design, it is necessary to understand the meaning of the words ‘System’ and ‘Design’ separately.

Definition of System:

A ‘system’ may be defined as a group of interrelated parts or elements designed to achieve a particular goal. A ‘system’ always exists within an environment which provides resources as inputs into the system, and that accepts outputs of the system. A ‘system’ is always doing something. For example, human body is a ‘system; while a rock is not a system (because it does not do anything).

The business system receives inputs from the investment in the form of the resources men, machines, material and money. The system also receives information from the environment so that management may define the goals, plans, etc. needed by the system.

A sub-system is usually a complete system functioning within a large system.

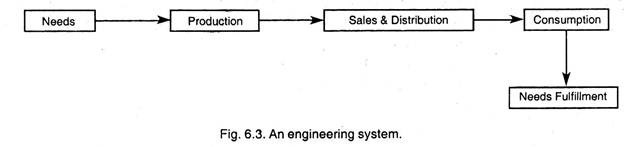

An engineering system usually utilises the human efforts, materials, machines and finance to achieve desired objectives. An engineering system comprises different stages of needs of production, sales and consumption as shown in Fig. 6.2.

There are three main systems, namely:

(i) Organisation system,

(ii) A system of management, and

(iii) Interconnecting systems.

Under these broad classifications there may be several other systems, like, manufacturing system, operating system, marketing system, planning system, control system. Organisation system has different sub-systems, namely engineering, production, finance, personnel, logistics etc.

Organisation system is the result of integration of systems of controlling, planning and organising. Operation system can have subsystems like money, flows, and personnel systems. Marketing system can have subsystems of pricing, advertising, sales, design, market research etc. Personnel system has subsystems of recruitment, placement, training and development, compensation, maintenance system etc.

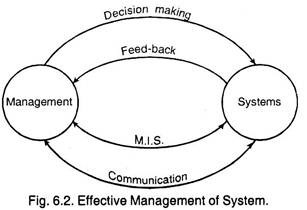

In order to control various functions, systems like Inventory control, network scheduling, resource allocation, quality control and inspection systems etc. are adopted. For better interaction between various systems, Management Information System (M.I.S.) and communication systems are necessary.

Systems are required to be managed so that they can perform their functions effectively in a coordinated way. Different systems are designed and developed so as to fulfill the objectives of the company. In order to manage the systems effectively, proper organisation based on traditional methods of depart-mentation must be developed.

All systems related to personnel must be managed, keeping behavioural aspects in view.

Motivational ‘need model’ and other models must aim for:

(i) Identifying the personal goals of individual workers,

(ii) Develop a work situation which will fulfill the individual goals while accomplishing organisational objectives, and

(iii) Provide fair compensation related to the work.

The system will work at optimum level when timely and relevant information are received by the management, and timely decisions are taken and implemented. Feedback for further corrective action is necessary.

Following aspects should be integrated for improving the management process:

(i) Information feedback system,

(ii) Understanding of the decision making process,

(iii) Management science techniques, like network, quantitative, and simulation approach, and

(iv) M.I.S. and electronic computer.

Now-a-days basic consideration of management is under certainty and for programmed decisions. As decisions taken under certainty and on the basis of laid down policy, procedure or a rule, are likely to be better and more economical, therefore efforts are made to programme the decision rules through computer, to enable faster, accurate and economical decisions.

Decision-making is treated as a central aspect of the managing. The concept of programmed decision is important because the ultimate goal is to provide purely programmed decisions. Efforts are made for more and programmed decisions through the use of management science techniques.

Therefore in order to achieve optimum results, management of systems through scientific, rational and logical approach is necessary.

System is a commonly used word with different meanings. Man is a system yet he has subsystems such as respiratory, digestive, and nervous system. But here we are interested in business or engineering system, where each sub-system operates in a logical way both internally and as a part of the larger system. The system is the flow of information.

The information flows into sub-system and causes certain actions. The sub-system operating within itself and it receives information from and sends to other sub-systems. The term system is also used as a methodical way of planning and coordinating the work to produce complex project.

A system can be considered as a structure of sub-systems, each having the following characteristics:

i. Inputs,

ii. Transformation process,

iii. Output, and

iv. Feedback.

A ‘system’ may be defined as a group of inter-related parts or elements designed to achieve a particular goal. A ‘system’ always exists within an environment which provides resources as inputs into the system, and that accepts outputs of the system. A ‘system’ is always doing something. For example, human body is a ‘system’ while a rock is not a system (because it does not do anything).

The business system receives inputs from the investment in the form of the resources: men, machines, materials and money. The system also receives information from the environment so that management may define goals, plans etc. needed by the system.

A sub-system is usually a complete system functioning within a large system.

An Engineering system:

An engineering system usually utilises the human efforts, materials, machines and finance to achieve desired objectives. An engineering system comprises different stages of needs of production, sales and consumption as shown in Fig. 6.3.

A system can also be defined as an orderly arrangement of components (man, material, money, machine and environment) that are interrelated and act and interact with one another to perform task or function in a particular environment.

A system is composed of elements or subsystems that are related and dependent upon each other. A systems approach is a systematic and organised approach to get the task accomplished more efficiently, effectively and economically.

Subsystems:

Subsystems are the parts that make up the whole system, and each system in turn is a subsystem of a still larger system.

Open and Closed Systems:

A system is said to be an open system if it interacts with its environment. While it is said to be a closed system if it does not interact with its environment.

Classification of Systems:

Systems are of several types, and can be classified as follows:

(1) Conceptual and Physical Systems:

Conceptual systems do not exist in the form but may either exist in the mind like, time system (year, month, day, hour, minute, second etc.) or in the form of plans, accounting system, structure and classifications of policies and procedures. Conceptual systems are concerned with theoretical structures.

These systems are composed of ideas, while physical systems are concrete operational systems made up of materials, people, machines, energy and other physical things. These are also known as empirical systems and are derived from or based on conceptual systems and thus represent the conversion of concepts into practice.

(2) Social, People-Machine, and Machine Systems:

Systems made up of people are viewed as social systems. Important aspects of these systems are organisational structure and human behaviour. Examples of these are business organisations, government departments, political parties, social clubs etc.

Most physical (empirical) systems fall into the category of people-machine system, and most engineering systems fall in this category. Pure machine system is difficult to think, as every machine system needs people may be to operate or control.

(3) Natural or Manufactured Systems:

Natural systems are available in nature. Ecology of life is a natural system. Examples of this system are solar system, water system of the world. Manufactured systems are formed when they gather in a group with certain objectives. Examples of this system are communication system, transportation system, business organisation system, production system etc.

(4) Adaptive and Non-Adaptive Systems:

Adaptive system is the system which reacts with the environment in order to improve performance or functioning.

(5) Sub-Systems and Super-Systems:

Each system is a part of a larger system. Smaller systems within the system are called sub-systems. Extremely large and complex systems are called the super-systems.

(6) Stationary and Non-Stationary Systems:

Stationary systems are those systems whose properties and operations do not vary significantly e.g., high school system, time system, solar system etc. Non-stationary systems are those systems which vary frequently, like R&D laboratory, an advertising organisation.

Design of System:

The engineering ‘design’ means an activity of which the purpose is to fulfill human needs related to the entirely technological factors of the outline. Thus ‘design’ process is an activity to convert the resources into systems economically to meet the human needs or wants.

In this way we can say that ‘system design’ means utilising the human efforts, materials, machines and finance to fulfill the human needs or wants.

With the advancement of science and technology, modern systems are becoming larger and larger and more complex because of the increasing complexity of modern industrial, military, aerospace and business requirements. These systems have computers, communications and large number of controls as their sub-systems is interconnected to form a complex system. This subject is gaining very much importance now-a-days.

Designing a System:

When the needs arise, a system is required to be designed.

Need gets the shape of system in the following stages:

1. Needs analysis, to explorate potential needs.

2. Development of possible system.

3. Comparison of system needs and proposed system capabilities.

4. Review and modification of possible system.

5. Revaluation and decision to go ahead with the system.

1. Needs Analysis:

From the definition it is clear that the identification of actual needs is the first step in the design of any project. This need is observed on the socio-economic sense. This factor is very important as wrong judgment of need may cause the project to be failure because of no demand. Market research is conducted for making need analysis, for which habits and behaviour of the people in socio-economic system is kept in mind.

While conducting the market research, the needs of the people, when the product is likely to be ready for sale are considered.

We shall have to be cautious against factors like:

(a) Changes in consumers taste.

(b) Ability of the competitors to offer better products.

(c) Development of an entirely new technology making the product obsolete.

Actually it is very difficult to make reliable estimates of the future situations. But by way of systematic approach, experience and set of techniques, we can gather sufficient information.

Basic Need Requirements of a Product:

A product, therefore, must satisfy the following basic need requirements:

(a) Consumers taste. This must include the habit, social belief, social customs and environment in which consumers are living.

(b) Prosperity of People. Peoples’ need changes with the change of their per capita income.

(c) Adoptability to Social Change. Product must be evaluated with the property of the flexibility of accommodating and adopting the social change.

(d) Conformity with the economic policy and law of the country. It must be according to the economic policy and the law of the country.

2. Development of Possible System:

As stated above, after knowing the needs, next step is to develop a possible system. For this, several alternative systems are listed and considered, out of which best one is developed. The various alternatives may involve different costs and different probabilities of success. Out of these, best possible system is selected with the help of different objectives and then it is developed.

Objectives of Possible System for Selection Criteria:

Following are some of the important objectives which must be considered while selecting one system for development:

1. Initial cost.

2. Production cost and maintenance cost over a specified period.

3. Reliability.

4. Performance.

5. Weightage.

6. Efficiency.

7. Safety.

8. Profit over a specified period.

Generation of Alternatives:

Having known the needs or requirements, different alternatives are generated and best among them is selected and developed further for execution. Thus selecting best method among available alternatives is a decision making process.

Generation or listing of various available alternatives is an important task as one method out of these is to be selected for implementation. Hence care must be taken to list all the possible alternatives which may even seem to be unfeasible in the first stage. This also helps in getting new and good ideas.

3. Comparison of System Needs and Proposed System Capabilities:

As explained above one best alternative system is selected and is then developed. When this system fully developed is compared with that of basic needs or requirements, if anything is pointed out then it is noted for correction and further consideration.

4. Review and Modification of Possible System:

There is room for improvement, especially for any untested new system which represents a significant departure from the way the things have been done in past. If the system is at all complex there are bound to be some things neglected, some false assumptions and some errors in reasoning. Also there are usually a number of ways to simplify and streamline the system which has been overlooked ordinarily. Many worthwhile changes can be made and occasionally an important improvement.

Therefore, the whole system is reviewed and tested with respect to principles of system and procedure design. At this stage it is important to correct deficiencies and incorporate as many improvements as possible before taking the decision to go ahead. Before final approval, it is also advisable to obtain suggestions from supervisors and other workers as they are in best position to detect flaws and deficiencies in the system.

5. Revaluation and Decision to go ahead:

The modified system is once again revalued. It aims to find whether this will be a beneficial system, fulfills all needs and there are no technical, social, economic and legal problems.

Apart from this a laboratory model of the product is to be made at this stage (generally after feasibility report) and tested for its performance characteristics to study the efficient achievement of the set goals. Then a criteria for performance is set in terms of materials, strength and durability. This test is also to be continued in terms of economic changes in the society at regular intervals in the light of advancement of science and technology.

Once the standards for evaluation have been set for the efficient performance of the subsystem of the main system. These sub-systems have to be synthesised in the form of prototypes which are to be used for further trial, progress and refinement work.

They are to be made with correct physical appearance and layout but using non-production and hand building methods. Once the prototypes have been tested, a check has to be made for its profitable production at large scale.

System Design v/s. Product Design:

System design and product design are purely two different terms and to distinguish them clearly their comparison is given hereunder:

System design refers to the design of a collection of components through the conceptual modeling. Components of a system represent the system in hand e.g., an aeroplane is a physical system with component as fuselage, wings, engine and controls, whereas an engine may be treated as a system comprising inlet compressor, diffuse combustion chamber, turbine and nozzle. Each of the above listed items may referred to as products if considered individually. Thus, engine may be the product of a system consisting of moulding, machining, jig boring etc.

In principle, product design proceeds through the same steps as system design. This is obvious in view of the fact that both systems and products are based upon certain human needs and their development must be optimised in the same way. System design and product design, therefore, proceed through same ways and means and the study of one is complementary to that of the other.

System Requirement:

In order to judge how satisfactorily an existing or proposed system is, several requirements are considered.

Some of the important requirements to be considered are following, which help in judging the success of a system:

1. Fulfill its purpose effectively.

2. Require minimum time to process and implement.

3. Provide complete set of plans, so as to minimize confusion at a later stage.

4. It should cost less in the long run than any other system.

5. Be adoptable to changing conditions.

6. Must be acceptable to the management and the personnel engaged in its operation.

7. The plan of the system must be in accordance with the policies of the country and structure of the company, and the requirements of the law and government agencies.

8. It must give more benefits than available from other alternatives.

Overall Objectives of a System:

A system has many objectives like performance, reliability, cost and schedule. All these factors are required to be considered in the design for any system. Hut depending upon the application and the customer requirements their weightage varies, some system may stress performance, other reliability, others cost and some other schedule.

For example, design of a radar would stress more for performance and reliability, while a mechanical screw jack for the use in cars would require more stress for cost and less for performance and reliability because of the difference in requirements. Therefore, it is necessary to consider each system separately and determine the relative importance of various objectives in the proper perspective.

A list of such objectives which would be used as guideline is:

1. Performance,

2. Reliability,

3. Cost,

4. Schedule, and

5. Maintainability.

A different individual may add a few more criteria. The importance of the criteria very much depends upon the requirements of the final objectives.

1. Performance:

The most convenient way of describing the performance of a system is its efficiency.

However the description of efficiency may vary from system to system as given in the following examples:

Performance of a thermal power plant may be measured in terms of ratio of energy output to thermal energy input; some persons may describe the performance in terms of Carnot efficiency.

Performance of an electrical machine may be described in terms of efficiency at a given load.

2. Reliability:

Reliability is a measure of successful performance of the system. Most accepted definition of the reliability is: “It is the probability of a device performing its purpose adequately for the period of time intended under-operating conditions encountered.”

The reliability of a system is the function of reliability of each of its components. If the total reliability of system, as derived from the reliabilities of elements is less than that of the system desired in design, than for improving the reliability, quality of the components is required to be improved.

For improvement in the reliability of complex system, considerable efforts are made on the components. Use of transistors instead of vacuum tubes is the example for such improvement. A most useful method for this is the group redundancy. A group redundant system combines single elements into the logical functional groups which are operated in parallel.

The redundancy technique utilise two parallel elements to reduce the probability of failure. While in group redundancy, we provide each channel of elements which perform a function with another duplicate channel. Thus we get a normal channel and a redundant (or standby) channel. When the normal channel fails, the standby channel is switched on.

3. Cost:

It is a very important criteria for starting a project and therefore a detailed analysis of the cost is essential in the initial stage of the design. Costs are classified as (a) fixed charges, (b) Variable charges, (c) Past investments etc.

4. Schedule:

Schedule is directly concerned with time as ‘time is money’. Now-a-days very much stress is being given on schedule, and modern schedule control tools like C.P.M. and P.E.R.T. are used for the purpose. Delay means loss of man-months of efforts, production cost increase and bad image on the consumers.

5. Maintainability:

Maintainability of a system may keep the reliability within prescribed limits. “Maintainability can be defined as the probability that a failed system will be restored to operatable condition within a specific time, when maintenance action is initiated under stated conditions.”

Thus it is a function of design and personnel concerned and, therefore, it can be improved by providing accessible test points, spare parts and necessary equipment’s for undertaking repairs, and by providing training to the operation staff for maintenance.

Advantages of Following Proper Systems:

i. Reduction in the operating time cycle.

ii. Lowering the inventories.

iii. Reduction of errors in estimating the costs and predicting the delivery dates.

iv. Elimination of avoidable operations and activities.

v. Faster working capital turnover and reduction in working capital requirements.

vi. Faster implementation of decision-making and feedback thereof.

vii. Effective supervision.

viii. Strengthening of organisation structure.

ix. Better communication.