In this article we will discuss about the concept and process of benchmarking of a company.

Concept of Benchmarking:

The concept of benchmarking was pioneered in USA by Xerox Corporation in 1979.

Benchmarking is defined as the continuous process of measuring the products, services, and business practices of a company against the toughest competitors or those companies recognised as industry leaders.

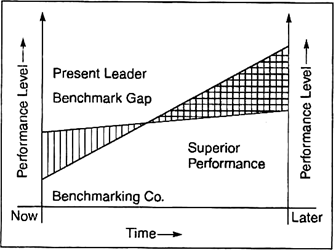

Benchmarking is the search for industry’s best practices that lead to superior performance. It is a systematic way of comparing and improving the activities carried out and services provided by a company. The chart below shows the achievement of benchmarking of a company.

Benchmarking is not merely the comparison of time, cost and quality. It looks at the processes behind those results. It is extended to the learning of processes, standards, policies, attitudes and culture of organisation which are best in class. Further, benchmarking applies not only to manufacturing activities but has an application in other activities also.

Conceptual Framework:

1. Benchmark is a standard or excellence or achievement against which other similar things must be measured or judged.

2. Benchmarking is a process of comparing results, outputs, methods, processes and practices in a systematic way.

It is the process of:

(i) Figuring out what to benchmark?

(ii) Finding out what the benchmark is, which is the standard of excellence?

(iii) Determining how it is achieved. What methods or processes produce results?

(iv) Deciding to make changes or improvements in one’s own business practices to meet or exceed the benchmark. Are we capable of changing the practices or methods? Will they result in better services for customers?

Process of Benchmarking:

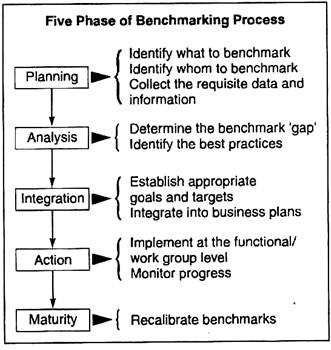

1. There are five phases of benchmarking process, as illustrated below.

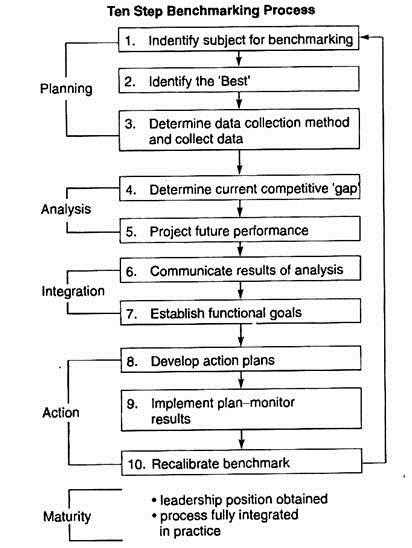

2. There are ten steps for the above process. These steps are charted below.

Benchmarking is conceived of as a ‘target’ in which the information gathered during activity analysis stage is not only used to make the activities more efficient and productive but also to provide scope for value analysis and value engineering.

Here, value analysis and value engineering refer to exhaustive analysis that categorises activities according to whether they add value to the output of an activity or process.

Value added activities transform work- in-process in ways that customers perceive as beneficial. Non-value added activities are either reduced or eliminated. The value added activities are subjected to improvement for the purpose of benchmarking.