The following article will guide you about how to improve performance to beat the competition.

Introduction:

Whatever be your background and line of operations you are always confronted with the problem of doing things the right way at the first instance. In the present context of shrinking world where markets and economies are coming too close to each other, the pressure on production and service sector is increasing day by day. Time for trial and error is gone.

There is now no option but to do the right things in the right way, efficiently and competitively. A businessman at the international level is also no exception; he too has to undertake business activities in the same fashion. He has to fully understand how the others are performing their job.

A successful person and/or organization would be one who understands how others are performing or going to perform otherwise he would not be able to understand the capacities, capabilities and limitations of the other parties that he is going to work with or against.

Understanding the operations the organizations that one works with, is as important for him, as it is for them. This knowledge would motivate the person to find amicable solutions to numerous problems that are encountered in actual trading operations for achieving the personal and organizational goals.

If you visit the production department of any organization you will find three words very prominently displayed—Quality Productivity and Efficiency. These three golden words make or mar the performance of the people and the organizations. Companies take pride in imparting training courses for their employees to induct working habits for getting better results.

These are an integral part of any system so long they help to generate outputs which can be directly or indirectly converted into monetary terms. The importance of these three is so much compelling that it forces the organizations to create environments that tend to condition their employees in the most competitive way. These positive habits have to be embedding in the system in order to get the best outputs.

The quality of work, productivity of output and the efficiencies of operations are the deciding factors of success in the present competitive world. You can measure up to the challenge by just being more competitive than your competitors.

This state of affairs can achieve if you have learned and practiced the integrated approach through the QPE route. It does not matter what is your background but so long you want to be successful you have to infuse the QPE approach in to your working habits.

The Profit Motive:

The great inventors and innovators of the past and present have fueled the industrial revolution world over. The power no longer is through the barrel of the gun but from the economic strength. This economic power drives its energy from the industry and commerce, which represent a bundle of need fulfilling activities.

These needs are nothing but open or hidden desire of make or gain profits or advantage from the goods and services that are offered in an area that he operates. Nobody would be doing anything if the profit motives were not there.

It is a strong motivator and it causes many a great innovation to retain the profits. Whether it is government or an individual their profit motive is always embedded in their acts through men, material and money.

Sometime the profit motive is obtained from the market place and sometimes indirectly, and if both dry out then so does the moving force behind them. It shifts to another area to repeat the action all over again. It also compels the producer or the providers to find ways and means to retain profitability.

The profit margins are obtained from the goods and services that one provides to the consumers as against your competitors. What you produce, how you produce, how you deliver, and how you interact with the feed hack are the basics that would decide whether you are in or out of the business.

What you produce is decided by the convenience need factors of the consumers. If it does not add to the convenience need of the consumers or to do their jobs in a easier and better way than it is worthless.

Sometimes the consumers might not be aware of what they could have, but in such a situation you have to educate them, tell them of what you could do for them in the form of your products and services to meet their desired needs and to make their jobs easier, and economical too.

How-you-produce is related to the available technology or your own ingenuity and enterprise. All have limiting physical factors so what are good today may not be valid tomorrow. This time gap between today and tomorrow gives you time to evaluate as to how your competitors are doing the same activity.

If there were no competitors then one could perhaps continue in whatever one was doing and the customers would have no choice but to Queue-Up in front of you. The situation changes drastically when you have the competition. Under such conditions how you produce would be decided not only by your competitors and consumers but also by the economics of production.

You have to keep one and only one factor in mind that whatever technology and/or methodology that you might adopt must give you net returns. This factor has significance in the present context of the open market syndrome taking roots under World Trade Organization (WTO). You have to bring in the sense of competitiveness in your operations.

Sometimes it is more practicable to source components and sub-systems outside of your production lines or to infuse the more efficient systems from outside. Take the case of carmakers. They concentrate on the basic designs, critical components and or sub-systems that might constitute only say 30% or so of the total cost and the rest is procured from the outside vendors.

As a matter of fact present tendency is gaining momentum when the developed countries are looking for vendors even outside of their national borders especially in the developing countries where the costs are comparatively lower.

Without going into any details on this topic, I would summarise that you have to take this decision on how to produce sooner or later in order to be competitive in the market place and how you do it would depend where you stand in the market vis-a-vis your competitors and consumers.

How you deliver is again another important factor. What you produce must be available to the consumers in the right condition, in the right quantity, at the right price and just right in time. In this global village concept of the market the consumers have the choice factor in his favour.

He makes the decisions on the spot or in the shortest of time and unless he has some sort of binding for you, he is very likely to go for the next alternate. The distribution channels for your products and services must take the least route and time to the market. The length of the route and the time both are related activities and add on to the net costs.

The net time and distance between the producer and the consumer have to be shortened with least numbers of blocks. This concept has special significance when you are dealing with bulk goods in the overseas markets. The thumb rule is -know more (about your competitors, tell less (to your competitors), act now, react fast, plan for action and plan ahead for change, before your competitors do so.

Forget the old saying of slow and steady wins the race instead they now lose the race. If you have done your homework well, then you are on the way to make the best delivery of your goods and services.

Having delivered the goods and services is but one part of the total job. The activities starting thereafter are as important as the goods and services that you provided to your target audience. These activities are related to the feedback from your target audience.

The feedback: In the home, in the market place and also within your organization you are confronted with numerous signals from the target audience one that makes tremendous difference between success and failure is related to the feedback. How you act and react to this feedback is vital for you and your organization and to your existence.

Sale done is not the end of the game rather it is the beginning of another game more crucial than the earlier one. This feedback only tells you as to what you produced was good or bad. Both good and bad actions at the market place send some signals back home. You have to worry about the bad ones then the good ones.

The good or the positive signals move in additive steps but the bad one’s progress in steps like wild fire. In business never believe—no news is good news—, rather —no news is always bad news. The silence on the part of the audience or the target market/ customers is strongest indication that something is very wrong.

If you too are silent then be sure your customers have already started moving in the other direction leading away from you. A happy customer will have the tendency to come back to you a non-communicative customer will perhaps never come back to you.

So always plant ears in the market to listen. Plant eyes in the market to see and plant hands in the market to feel. All these feedbacks must be fed to your corporate brain to start the whole process all over again to improve your performance for still better results.

Know Your Competitors:

You cannot beat your competitors unless you know more about them. The more you know about them the easier it would be for you to sort out strategies for doing better than them. Your competitors are also your net assets in the game of survival.

You have to know not only what they are doing today but also what they will be doing tomorrow and how they would react when you make a move. Your knowledge about them can only motivate you to plan your strategy to produce the right quality at a price to beat them.

Know your competitor is a very general statement, how you do and go about doing it, is not so easy. The first question that comes to mind is who are the competitors and the second question is what are they doing that is coming in your way. In the present context of information and communication revolution, it is not difficult to gather basic data about the competitors.

We can easily gather secondary data from the published literature of the organization, the plant and equipment, production and sales and financial position etc. The second part of the job is of immense value to you. You have to find out what your competitors are doing or going to do that would directly or indirectly interfere with your free movement in the market.

This part of the exercise would require not only the sensitive primary data gathering but also its analysis, interpretation and conclusions. Anticipation and countering are the games that we play in order to survive in the market place.

The person in power knows the routes and the sources to gather necessary information. In general the data bank on your competitors is one of the source for such sensitive information.

Periodically you can fill additional information from following sources:

i. Production capacities,

ii. Spare capacities,

iii. Alternatives capacities available,

iv. Orders on hand and in the pipeline,

v. Market share and its movements, past present and future,

vi. Financial position,

vii. Labour relations,

viii. History of labour unrest,

ix. Managerial strengths and weaknesses,

x. Line of authority,

xi. Key positions in the decision-making routes,

xii. Track record in other products,

xiii. Any past or pending legal cases affecting the organization,

xiv. Strong points of the products and/or services,

xv. Sources of raw materials,

xvi. Transportation network for the raw materials origins and products destinations,

xvii. Any plans for expansions and /or diversification,

xviii. Any tie ups for technology marketing or distribution net work,

xix. Any discontentment feelers amongst the middle order management and or between the management and owners/investors/promoters,

xx. Comparative data on your products/services and that of your competitors, and

xxi. Personal information on the key persons of your competitors especially on.

a. Place of residence,

b. Educational background,

c. Years of service,

d. Track record,

e. Tendency of migration,

f. Family details and linkages with any known power factors in political and/or financial circles,

g. Club memberships,

h. Hobbies,

i. Known weaknesses,

j. Financial position,

k. Attitudes and aptitudes especially with regard to risk taking abilities,

l. Life style,

m. Value in the organization, and

n. Miscellaneous information not covered above.

Remember when you are confronted with a competitor you are in fact confronted with an individual or groups of individuals. Amongst them, an individual would be the most influential one or be the power centre. If you could understand that individual’s mind, then half of your battle is won and the rest would depend how you play your cards.

Another crucial point about your competitors is the source of their power. You have to identify that source of power and find ways and means to control it or confront it. You can understand this point from a very simple example. You cannot touch boiling water; it will burn your fingers.

But if you remove the fire that gives heat to the water, the water will lose its heat and cool down and then you can handle it the water the way you want. The strengths your competitor too has some power source and you have to find just that very source, if you can manipulate or control it. Your competitor will come under your spell.

The QPE Approach:

In order to provide the right quality, quantity and the right price, it is important for you to adopt and practice an integrated approach to your business so that the concerted efforts of all in the organization work towards one goal and that is just to return profits to the organization, to let it live and live profitably.

If the organization survives it can support others, if it goes down everybody has to fly away in search of new pastures. How we can do it, there are many theories circulating in the world and even within the organization many ideas and suggestions are available. I am not going to teach you any such theory but would suggest you an approach to tackle this problem.

This approach might sound like Total Quality Control Concept as advocated by many in the west but this basic approach simply integrates the three elements prevalent in any organization.

They are no doubt practiced by the organization at all the levels but when the problem is of survival in a global market you have to do something extra to beat the competition that extra element you can generate through the QPE route.

The starting point of this process is the individual, that is you. If QPE could be transformed into a scale that what you measure on this scale would define your QPE factor and the collective sum of all the employees would indicate that of the organization. The application of this factor is not limited to your work place but also where and how you live and want to live or lead.

What is QPE?

(Quality, Productivity, Efficiency)

The convenience needs of the consumers are translated into products with the help of available technology. The product is engineered for a price level through induction and practice of productivity concept and finally the operational efficiency transforms and places the products in the market place at a price tag to induce the customers to buy and come back again for more.

When I say the products I am not differentiating between the consumer goods consumer durable industrial products, systems and even raw and or semi processed goods, and all kinds of services, all are grouped together as products and services, together referred as products or products/services.

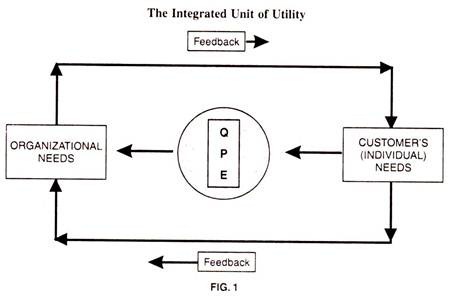

The concept of QPE has on its one side the organizational needs and on the other hand the needs of the consumer. In between is the process screen of QPE. This forms a closed circuit loop of activities that regenerates itself getting energy from each step as it moves forward. The total concept can be termed as the “Integrated Unit of Utility”.

This concept can be illustrated in simplest form as follows:

The organizational needs are to get the maximum return on the investment by providing goods and services to satisfy the needs of the consumers and this is achieved through the QPE process. QPE is a continuous regenerative process. Its one step complements the next one.

The existence of one depends on the survival of the other. If the consumer needs are at variance with the organizational needs then the QPE loses its place and the system flops. On the other hand if the consumer needs are compatible with the organization’s but cannot be translated into profitable business then also the system will flop.

So in order to make the system run its full cycle you have to have the right product at right price in right quantity available to the consumer meeting his convenience needs for it. Thus the needs for both the organization and the consumer are mutually met. Each satisfying the other and in return the producer gets profits and the consumers spend money to get more convenience.

Quality, Productivity and Efficiency are all interrelated activities. As said earlier the QPE of an organization is the collective sum of the QPE of the individuals of that organization. The efficiency of your operations will catalyze the productivity-oriented approach in your organization and the quality of the final product and/or service will only set the chain reaction for higher efficiency and productivity.

For a successful venture it is necessary that all these three factors are implemented concurrently and not as separate identities. Two good and one bad or two bad and one good would be just as bad.

In today’s world, and in the years to come, when the global competition is cutting into every nook and corner of industry and commerce, the organizations can ill afford not to be producing goods and services of highest quality and at prices lower or compatible then their competitors and still be able to get enough returns to justify their existence.

1. The Quality:

Definition:

Quality is the integration and utilization of facilities and minds for perfection of reproducibility of performance with zero defects and compromises. Quality can also be regarded as performance without fault at affordable price.

Quality is a subjective view directly dependent on the demand and supply conditions and it keeps on changing with the technological innovations and the changing patterns of consumer tastes. It also depends upon what your competitors are doing. So for a given product there is a fixed relationship of quality, price and the consumer.

Quality in itself has no meaning. A product or service in a working condition and meeting certain needs or conveniences of the consumer is a product only but whether it is good or bad is a subjective view point and has a relative degree comparatively.

It can be good or bad only if it is compared with compatible alternative products that threaten to replace it from the market place due to their price and/or due to performance.

Your competitor’s Price and Performance are the two points that you should never over look and keeping them mind you must evolve your own strategy for countering them and staying in that market.

The performance of your products will be decided by the available technology and engineering application to transform a concept in to a reality. The quality aspects of all the inputs at the beginning are very crucial and are in fact the deciding factors of the output.

The quality control or in short QC is no strange word for us. We know too much about it and yet when we see our place in the world market why we are not able to sell our quality. If we look at ourselves in the mirror the mirror will show us the reality. The reality is that firstly we do not fully understand the idea behind the quality concept and secondly this idea does not find place where it should be practiced.

Its playground is not only the production line and each and every person on that line, but everybody associated with the organization has to be involved in this concept. The quality is the collectorate of the efforts oriented towards one goal and that goal begins and ends with the consumer in the market.

He decides whether what you are producing is good or bad product or service. Even if the consumer in the market says that your product is of good quality but that quality in itself is not sufficient if it cannot be translated in to business giving your organization returns to justify the investors’ confidence in you.

So you must understand that quality is not a benchmark in the production line, neither it is confined in certain manuals and departments, it is also not a fashion or a stamp to show off to the world like many organizations are using or trying to use the ISO certification as their quality hall mark.

In fact this is simply to tell you in the first place that the process and the system that you have adopted in your organization are okay but this certificate in no way guarantees that your product would be of good quality or not.

No doubt the ISO certification does help when you are dealing at the international level because in the absence of any solid proof of your quality the organizations across the borders would know that you are a systematic and standardized organization and this is the first step. Your quality is your identification certificate and this is what you should try to improve.

You cannot induct the quality in your work overnight since quality is not a system. It is a culture and all cultures take time to get roots. Your QC must stand for the quality culture. It must cover the whole of the system, men, material, technology, processes, controls, sales and purchase, service and recovery.

This culture builds up slowly and gradually. It unifies the various elements of the organization like a chain. The strength of this chain will be the strength of all the links that constitute and form the chain. But the weakness of this chain will be the strength of the weakest link of this chain because it would snap only at the weakest link and not at the strongest link.

When our country is opening up for the global market you have to assure at first that your strongest sales point is the quality. Application of this quality can build your business empire through the infusion of productivity and efficiency. The productivity and efficiency can give you the price manipulative powers but that power has to stand on the pillars of quality.

In order to attain specific levels of quality standards it might not be difficult for the ongoing organizations but for new players it is a hard task. They could either depend on the outside infusion or take the long route of trial and error method. The logic is always in the favour of outside infusion as collaborations or technical tie-ups.

This infusion route helps you to learn in a shortest possible time the vast knowledge collected by your collaborator since he worked for much longer than you in perfecting the system. He knows the hows and whys, dos and don’ts. All such information is piled up in his document termed as the technical knowledge or the know-how of doing the things in the right way at the first try.

When you tie up with him he tries to infuse that collected knowledge in your system. How much you are able to absorb would depend on how much you are able to understand and put into practice. You must understand that collaboration is the intermingling of two cultures and if yours own is not ready then the infused culture would produce something but not at the level of the infused one.

The basic prerequisite for absorbing maximum from the collaborator’s culture is to have your own strong quality culture which only can understand what the other side is saying or implying to say.

How to achieve quality levels commensurate with the market and the organizational requirement is a million-dollar question. It has no universally acceptable definition and no universal golden rules can be prescribed for achieving and maintaining the quality. Its conception and application vary from company to company, from plant to plant.

In nut shell everybody associated with it directly or indirectly has to find his best mix from the known variables within the organization and from position of the product in the market place. Your products have to perform in a predetermined pattern depending on the technical parameters for a given technology or process.

These parameters will define the quality levels that can be achieved for performing predetermined services or out puts from your products and within those limitations you have to strive to reach a stage of zero level of NO GOOD components/systems services and/or products.

You have to make sure that the GOOD products that leave your factory doors are 100% perfect and your customers do not find faults in them. If your customers find the fault then all that you did in house was not correct or at least someone in your system did not do his or her job correctly. If it happens then you should not only be able to pin point the source of that problem but also be able to eliminate that problem from any recurrence in future.

While discussing the quality let me point out one of the potent poison of quality, it is called the COMPROMISE. Yes, the habit of compromise at any level in your organization that affects the performance, durability, cosmetics and the application of your products, is the deadliest poison that you can think of.

It just kills the system quickly or slowly. So you have to ensure that whatever is defined as the parameters of your product at the drawing board stage is inducted into the product manual, has to be met under all circumstances otherwise one compromise would lead to another.

Remember when you are engineering a product you do almost 8/10th of the job; balance 1/10th you do at prototype stage and rest at production line.

Once you reach the production line the parameters of the raw materials, the process, the methodology, the physical and chemical properties, the dimensions, the expected efficiencies, the test and recording, the operational and maintenance manuals, the packing and dispatch etc.

All are fixed and no body at any stage in the line has the right to alter anything. You do it right, the quality concept will take care of itself. If at all any change is to be done to enhance the performance or the adaptability of your product due to any reasons then the whole process has to be repeated right from the drawing board stage.

Finally allow me to summarize some of the more commonsense steps that ultimately assist you to maintain the quality concept in your system. These are perhaps not new to you and most of you must be practicing already in your organizations, what if somebody is not?

1. The technical parameters of what is to be procured, processed, produced, packed and delivered must be clear cut in black and white without any ifs and buts.

2. All that goes in to the production of a product from the raw material to the finished product must be well documented into a manual and codified and its availability and circulation well known and specified. As a matter of fact this is your know how, protect it, groom it and perfect it regularly.

3. Any changes in 1 & 2 above must be reflected in the product manual.

4. You must have check system at every stage of production and must evolve a system that passes only the “100% Okay” components/sub-systems/systems.

5. Whatever and whenever any not-okay component(s) is/are found, it is not enough to scrap it; rather you have to find out the root cause and eliminate it.

6. Everybody associated with the product at any stage must be made to realize the cost to the organization for his not-okay contribution. Any not-okay contribution adds cost to the product and cuts the profits. Organization has to spend money to find what are not okay and then spend money to replace it besides the double cost of the component/service.

7. One of the most common problem found on the shop floor is that the testing instruments are not tested frequently enough to ensure what they are testing is universally true. For example if your man reports the width of a component as 4.25 mm then the end user located at 10,000 KM away must also get it as 4.25 mm.

This can happen only if your testing instruments are calibrated frequently and results recorded meticulously and subjected to verification audit. The person authenticating calibration must be independent and away from the line managers and even middle management level in the organization.

He must be responsible and answerable to the highest authority in the organization. Sometimes the re- calibration is done by outside agencies, in such cases proper certification must be obtained and in-house verifications done to ensure that the re-calibration has been done properly. The time cycle of re-calibration must be adhered to strictly.

8. If you have a good quality control system operating in your organization, it is only half the work done. The other half is the commitment and devotion of the hands and minds that make use of it. It has to penetrate the thinking and working of the people and everybody has to feel responsible for its implementation and be the QC person for his own job.

9. The domestic markets are very protective markets; here everything seems to belong to you. The market, the customers, the government machinery, the banking, the transport you name any thing all seems to be within your reach but situation changes when you enter or try to enter the export market. In that market all you have is your product.

So the first thing that you must ask your self is that are you producing for that market and before you reply you must satisfy yourself that your quality and performance are compatible with your competitors in that market. Many organizations failed because they did not answer to this basic question.

If your quality and performance are well established at the domestic front it would not be difficult for you to engineer your products for the overseas markets. The thumb rule is that those who are successful in the domestic markets through their quality and performances have greater propensity to succeed in the overseas markets as well.

10. Training and more training is another tool to achieve higher levels of quality and performance from your employees. So whenever possible expose your people to various training programs, this will broaden their outlook towards their work and improve their abilities capabilities and capacities for higher and better work and also it helps them to do the right things in the right ways.

11. The Life Expectancy Factor ‘LEF’: Many times you might have found that in the replacement market there are components similar to yours but very cheap, they do give the required service but need replacement frequently.

The only reason for this situation being the low Life Expectancy Factor or ‘LEF’ of these products. Now on the other hand compare the LEF of your components with those of the other world brands in the market. You might find that their LEF is high as compared with your components.

Before I proceed any further let me elaborate on LEF from a real case. In the case Bucket Tooth used in the earth moving machinery, the Indian and the overseas components both are made of same steel and have same dimensions and both are flame hardened but still the LEF of the Indian one is lower as compared to that from the specific overseas maker.

The difference is that the Indian maker after perfecting the design and getting the right performance froze design and with it the LEF was also frozen at that stage. But in the case of the overseas maker the R&D continued in enhancing the LEF to a higher and higher level. They surveyed the users and tried to find when and at which place(s) of the tooth the actual users found the maximum breakage.

They pin pointed areas for further developmental work to strengthen those very areas. How they did, it was their ‘know how’ and perhaps they will not part with it. But all established makers undertake similar exercises because for them it is the matter of survival.

When your price is same, your quality is same, your performance is same, distribution channels are fixed, at that stage where you go to keep your market share, at that stage you are left with no option but to use the LEF as your sales tool.

LEF is a cost additive item so you have to make a decision as to what extent you can go without losing the price advantage and the market share. The technological innovation is moving very rapidly. The model rotations with additional features appear leading to obsolescence.

The consumers also weigh the returns on their investment on your products and their performance as compared to the replacement for the new products. If your LEF is high then the cost to the consumer would be less, but on the other hand if LEF of your product is too high then market saturation syndrome sets in and you would be facing the dropping sales situation.

This is the most difficult situation. You have to find the optimum level of LEF that assures you continuity in sales on one hand and consumer satisfaction on the other hand, without losing any ground to your competitors.

Concluding this part I would only say that you must include the LEF in your QC and R&D efforts and make it a part of product development. Remembering that LEF of your components is the LEF of your product as well.

2. The Productivity:

Definition:

Relationship between given money value inputs to money value outputs.

After having established the quality, the next step is to get the output at such levels that it can take care of the cost to the company plus the profit margins and still be competitive in the market place. In fact productivity is the one tool in the hand of organizations to beat the competition.

When competition becomes severe the war is normally fought on the price front without sacrificing the quality. Your competitor always watches you under price war conditions as to whether you are making any compromises on the quality front.

The moment you do it your competitors would give you free publicity to tell the market where you are making the compromises and all your compromises become their strong and sales points. Quality is not a negotiable item but price is. So what you do is to find out ways and means to cut corners and the best way to do so is to increase your productivity.

Productivity is basically related to man-machine relationship. The manual output has certain physical limitations but the introduction of high performance machines and automation has a force multiplier effect. Its introduction not only increases the production but also lowers the overall price level.

But still the hands that operate those machines do not lose their importance because they are the one and only that will operate the machines in the new combination of man-machine relationship for higher productivity which means that the man on the machine is an important factor in the realms of productivity.

If you can motivate this man by providing extensive training, conducive work environments, well planned production and execution system, then no doubt this man will apply his skills to get higher levels of productivity. This is not Utopia but a thing of our own world and many countries and corporations are testimonial to this inter relationship.

The worker’s dedication to their work and most important to their organization is so important that no organization can afford to neglect this area if they intend to remain entrenched in the market. You can understand my point of view if you consider the situation of labour relations in organizations that are frequented by strikes.

In such organizations the management hires the hands only and not the brain in between those hands. This is the root cause of problems because his brain is working elsewhere, not where the hands are working. The brain tries to find ways to get better off the management and the management tries to get the better off the workers.

Each one tries to be the winner. The fact is that both are actually eating up the organization that suffers on either’s folly. The organization loses the productive man hours setting off a chain reaction of loses affecting whole of the system.

Let us consider a case of a highly dedicated and motivated worker as to how he conducts himself in his daily routine and you can manipulate the situation to understand what a worker might look like who is not conforming to these lines.

The Case of a Motivated Worker:

i. Early to work place,

ii. He is mentally and physically fit and present,

iii. Checks the day’s work schedule,

iv. Checks the tools of production,

v. He applies his mind to understand the production cycle of the job in hand,

vi. He makes fewer mistakes and ensures they are never repeated,

vii. He adjusts his pace of work so as to gain time and uses his time to communicate with his equipment and or superiors for better performance,

viii. He is communicative and expressive of his and others ideas and suggestions,

ix. He is evaluative,

x. He anticipates the coming problems and prepares himself to face them and/or warns or keeps informed the superiors and makes sure to face them and avoid them through alternate contingency plans,

xi. He values his performance and has positive attitude and aptitude,

xii. He is not critical but analytical,

xiii. He is not offensive but cooperative,

xiv. He feels responsibility for what he has and what he gives,

xv. He maintains his place and equipment neat and clean and knows when it must be subjected to regular inspection,

xvi. He is a hardworking man,

xvii. When he leaves his work place he prepares it for the next day,

xviii. He feels associated with the organization and tries his best for the organization,

xix. He knows his equipment and knows its limitations, and

xx. He knows the machine does not give results but he has to get results from it.

Well, these are some of the traits of a worker who has the tendency for higher productivity. The prime mover higher productivity is basically this man on the machine and he has to be integrated with the organization in order to get quality and productivity in the product and/service.

It must be understood that productivity is not a universally measurable identity. It varies from industry to industry but it assumes a competitive nature once you move in a competitive and compatible product range in the market place whether at the home or in the overseas.

In such situations this factor of productivity would decide the competitiveness of your products when you have to maintain the quality at the highest level and still be able to offer your products at prices marginally of competitive range as compared with your competitors. In the present days of global awareness and spread of consumerization, the consumers have the choice factor to their advantage.

In the protected markets the quality and price are negotiable depending on the level of competition, but this phase is gradually passing out. The tariff walls are falling down like the Berlin wall. The competition is heating up not only amongst local makes but also with the overseas brands.

The World Trade Organization (WTO) has given boost to the expansion of markets from the national to international boundaries. Now is the time of survival of the fittest. In this game of survival you have to produce goods and services of international standards and at prices compatible with those of other players in specified markets.

So the name of the game now is to produce or perish. This is the time for you to think over and review your whole system including that of the technology, methodology, equipment, service, men, material, finances as one identity of survival. Find out how you can integrate the required quality and productivity for turning out the right product at the right price and in right numbers.

Unfortunately no golden rules can be prescribed for above except that you have to work hard, get involved in the organization for one goal of producing quality at competitive prices and continuously monitor your inputs and outputs and everything that goes in between them.

Productivity is one such area that can, if handled properly, help you to survive and flourish. Do not limit the productivity culture limited to your shop floor but let it be followed and practiced by each and every department and in fact every individual of your organization.

The productivity culture has to permeate into all the functional areas. Everybody has a definite role in the organization. They are allotted a fixed time frame for the activities expected of them and the organization spends directly and/or indirectly net sum of money to get those activities done.

Any failure at any level by anybody simply adds the cost to the organization that is reflected in the form of higher end result costs and lower profitability. The flow of quality and productivity in an organization is assisted by the efficiency factor both will lose their significance if they are not efficiently implemented.

3. Efficiency:

Definition:

The ratio of net output to input in a compressed timeframe.

Similar to productivity, efficiency is also a ratio of the outputs and inputs with regard to a timeframe. It is important to note underlying overtones of time when we are measuring the efficiency of a system or an individual. Given the time anybody can do the required job if he has the ability to do the job.

But to do the job in the right way and in the minimum of timeframe is very important because for an organization time is always related to cost factors to the organization. The input has to be at the lowest level, whether it is as materials, money, utilities or even your own thoughts’ applications and manipulations.

Whatever be the form of the inputs, you have to draw the minimum from these reservoirs and turn them into the required out-put at the maximum level taking the least proven path and avoiding any failures and repetitions.

You must keep in your mind that these failures and repetitions will eat up your efficiency rating and reduce the net out-put. So the efficient ones would be those, who are able to do the required jobs, in perfection, in time, with minimum of time, without any repetitions and by using the minimum of inputs.

Long back I happened to visit the residence of a friend in Japan and was impressed by the neatness of the things and could not avoid asking the question to the lady of the house as to how she managed to keep her house in such a condition. She replied in a very flat tone that “I don’t dirty my house at the first place.”

These were very simple looking words but they explained a lot. If you do not dirty your work then you do not spend time to clean it. You apply this simple logic to your work and see what difference it makes to you. Keep everything where it belongs so that you know where to find it when you need it.

Time saved in such trivial matters can best be utilized for other more productive works and that would speak for your own efficiency. The organizational efficiency is nothing else but the net sum of the efficiency of its individual units and individuals.

The most efficient organizations are the most well organized one also. Such organizations have well-equipped communication system. The flow of communication both at horizontal and vertical levels of management is not only smooth but effective and perfect as well.

The efficiency and communication together form a solid network reaching out, to and from every source and destination- effectively. Ambiguities and— do it again—or explain it again—are the killers of your efficiency. Never indulge in them if you want to get the results.

It is not difficult for any organization to control the quality, quantity, sales and purchase but to do it efficiently is the most difficult task because it has direct relationship with the individual identity of the organization. It is influenced by the aptitude, attitude, habits and in general with the behavioural application to the required task.

Efficiency is inculcated gradually by orientation of the behavioural responses into the desirable kind of habits. The habit formation is achieved gradually by not doing the things contrary to the requirements. It creates a conducive environment that tends to draw the others into its folds of conformity.

If one out of ten is inefficient then the group behaviour would pull the odd man in line with the conformity of the group but the same is also true in the opposite. So the best thing in the interest of everybody and including the organization as a whole is to create a conducive environment for efficiency oriented habits from which everybody stands to benefit.

How we can do it is a matter of choice and the organizational goals but in general one can achieve it through training, counseling, guiding, and most important of all by communicating.

Remember an efficient worker always has time and an inefficient worker is always short of time because he uses his time to correct his inefficiency. It is up to you to decide which side you are and where you intend to be.

If you intend to be on the positive side then whatever be your job, understand it, do it now, do it correctly, do it quickly and think how you can do it in a still better way the next time. This is the golden rule and a mark of your efficiency.

The Need for Integration:

So far we have discussed the three basic elements of the corporate survival in this competitive and opening up global market. I do hope that you have understood the application and implication of each element for achieving the common objective of business.

But in operational reality there is the strongest need for their integration into one unit of utility for the individual in the organization as well for the whole of the organization. For an organization to be profitably engaged in the related activities it is important for it to produce goods and services commensurate with the demand and supply pressures of the market with regard to quality price and performance.

In order to do so the organizations have to produce products of equitable quality than their competitors, at a price compatible/lower than their competitors, have it deliver to the customers in a way better then their competitors or in nut shell they have to beat the competition and still make enough of profits to Justify their existence to themselves and to their investors.

How they can do it is a grueling never ending does or die task? The solution lies in the integrated approach through the unification of quality productivity and efficiency by everybody in the organization irrespective of what they are and where they are standing in the line of management ladder. This integrated approach will assist you in achieving the results- positively because;

Quality will help you to produce goods and services for providing highest level of convenience utility and comfort to the customers.

Productivity will help you to cut your output costs and also give you greater mobility in quantity.

Efficiency will help you to perform your above two tasks in the shortest of time and with minimum or zero level of wastage.

Conclusion:

When you infuse these three into your working habits you are bound to succeed as an individual. On the other hand, with the collective actions of all of the employees, the organization will also succeed in any given market. Therefore in future before you try to improve the organizational performance at first ask yourself what is your own performance level? Or in other words what is your QPE level.