Process Costing method applies to those industries, where the material has to pass through many processes for converting it into a finished product. This method is used in chemical products, oils, varnishes, soap, paints etc.

Process Costing is another method of Costing employed for ascertaining the costs of goods and services of Processing Industries. This method can be applied in the industries which are mass producing industries producing standard products.

In the case of Processing Industries, raw materials are processed in one or more process to obtain the finished goods or saleable commodity.

The terminology of CIMA defines Process Costing as – “the costing method applicable where goods or services result from a sequence of continuous or repetitive operations or processes. Costs are arranged over the units produced during the period”.

Contents

- Introduction to Process Costing

- Meaning of Process Costing

- Definitions of Process Costing

- Characteristics of Process Costing

- Features of Process Costing

- Fundamental Principles of Process Costing

- Stages Involved in Processing of a Product

- Examples of Specific Industries where Process Costing can be Applied

- Treatment of Important Items

- Joint Products and By Products

- Steps Involved in Computation of Costs

- Elements of Process Costs and their Accounting Treatments

- Transfer of a Part of Output to Warehouse for Sale

- Classification of Problems

- Industries where Job and Process Costing is Applied

- Difference between Job and Process Costing

- Advantages and Disadvantages

- Merits and Demerits

- Multiple Choice Questions and Answers

What is Process Costing: Meaning, Concept, Characteristics, Features, Principles, Stages, Examples, Treatment, Merits, Demerits, MCQ, Difference and Suitable For…

Process Costing – Introduction and Concept

This method applies to those industries, where the material has to pass through many processes for converting it into a finished product. This method is used in chemical products, oils, varnishes, soap, paints etc.

Process Costing represents a type of cost procedure suitable for continuous and mass production industries producing homogeneous products. In industries suitable for process costing, output consists of like units.

Each unit is processed in the same manner. It is difficult to trace the items of prime cost relating to a particular order, because its identity is lost in continuous production. It is assumed in process costing that average cost presents the most satisfactory cost per unit. Cost of production during a particular period is divided by the number of units produced during that period to arrive at the cost per unit.

In a paint factory, thousands of litres of paint are produced. It is difficult to trace the items of prime cost relating to a particular order for one hundred litres of paint. Under these circumstances, cost of production for a particular period will be taken and it will be divided by total number of litres of paint produced during that period to ascertain the cost per litre of paint.

It is presumed that same amount of material, labour and overhead is chargeable to each litre of paint produced during that period. It is necessary to understand the concept of process. A process is an organisational entity or section of the firm, in which specific and repetitive work is done.

Some of the various other terms used to describe a process are department, cost centre, responsibility centre, function and operation. A process can also be referred to as the sub-unit of an organisation specifically defined tor cost collection.

This sub-unit is concerned with specific operations. In process costing, particular attention is given to –

(a) costs relating to the process, i.e. both direct and indirect cost,

(b) period for which cost for the process is collected,

(c) completed units produced during the period

(d) incomplete units in the process at the end of the period and

(e) determining unit cost of the process for the period.

What is Process Costing – Meaning and Formula for Calculating Unit Cost

Process Costing is another method of Costing employed for ascertaining the costs of goods and services of Processing Industries. This method can be applied in the industries which are mass producing industries producing standard products. In the case of Processing Industries, raw materials are processed in one or more process to obtain the finished goods or saleable commodity.

Further, the finished product of the factory is in the form of identical units which require the same quantum or amount of material, labour and overhead per unit. Process Costing, therefore, aims at ascertaining both the process costs and the costs of units processed in each of the processes (both total and per unit).

More specifically, it aims at ascertaining the average cost of the product which can be achieved by dividing the total process costs by the total number of units produced.

Hence, the simple formula used to compute the unit cost is –

![]()

Process Costing – Definitions

Process costing as a method of ascertaining the cost has been defined by different experts and professional institutions in the manner stated below:

According to I.C.M.A., London, Process Costing is, “that form of operating costing which applies where standardised goods are produced”.

Kohler defines Process Costing as – “a method of cost accounting whereby costs are charged to processes or operations and averaged over units produced”.

Process Costing is defined by CIMA, London as that form of operation costing which applies where standardised goods are produced. Wheldon has viewed Process Costing as a method of costing used to ascertain the cost of product at each process, operation or stage of manufacture.

Ronald W. Hilton opined, process costing is used in production process where relatively large number of nearly identical products are manufactured. The purpose is …. to accumulate costs and assign them to units of product.

The terminology of CIMA defines Process Costing as – “the costing method applicable where goods or services result from a sequence of continuous or repetitive operations or processes. Costs are arranged over the units produced during the period”.

Like unit costing, Process Costing is also a form of operation costing as distinguished from specific order costing.

In case of unit costing, production of a single product is brought about by setting up a separate plant. In the case of Process Costing, however, production follows a series of sequential processes for either a single product or a limited range of products.

The aim of Process Costing is to determine the total cost of each operation and to apply this cost to the product at each state of process. It will then be possible to ascertain cost per unit for each operation or process and in total.

Main Characteristics of Process Costing

The main characteristics of process costing are:

1. Manufacturing activity is carried on continuously by means of one or more processes that run selectively or parallely.

2. The output of one process becomes the input of another process until the final products are completed.

3. The end product usually is of identical and standardized units not distinguishable from one another.

4. It is not possible to trace the identity of any particular lot of output to any lot of input of materials.

5. Joint and or By-products occur in one or more processes. These joint and by-products may require further processing before they can be sold.

6. At the end of the period, the incomplete units in a process are restated in terms of completed units i.e. equivalent units.

7. Goods may be transferred from one process to another process not at cost price but at a price nearer to market price i.e. transfer price. This policy highlights the inefficiency and losses occurring in a particular process.

Top 5 Features of Process Costing

The various features of process costing are as given below:

1. Production activities are undertaken on a continuous basis. That means, production is not undertaken against the customer’s specific order as in the case of Jobbing Industries and Job Costing.

2. Raw materials are processed, usually, in more than one process sequentially. Hence, the entire manufacturing activities are divided into a number of processes which take the form of cost centres. Separate accounts are kept for each of the processes to arrive at both the element-wise and process-wise costs, both total and per unit.

3. The materials processed in one process are transferred to another process for further processing. That means, the output of one process becomes the input for the next process until the finished product (i.e., saleable commodity) is obtained.

Hence, the product (i.e., output) of a process is called a process product. The Process Product of the last or final manufacturing process in the finished product of the company.

4. The finished product or output comprises of like units and they are not distinguishable from one another. That means, output is uniform and the units are identical. Hence, the products and processes are standardized.

5. Since the output is uniform and the units are identical, the cost per unit is ascertained by dividing the cost of the process (of a period) by the number of units produced during that period.

Further, some processing industries may undertake the production of more than one product simultaneously in one or more processes of production.

Besides, the processing companies may also obtain one or more by-products in addition to the main product. Of course, process losses usually occur in one or more processes as it is unavoidable.

Fundamental Principles of Process Costing

The fundamental principles are as follows:

1. Cost of materials, wages and expenses (both direct and indirect) are accumulated for a period and classified by departments or processes.

2. Adequate production records of output and scrap of each process or department for the period are maintained.

3. Total cost of each process during a period is divided by the number of units produced during that period to get the average cost per unit.

4. The cost of normal spoilage is included in the cost of good units produced. This increases the average cost per unit.

5. As products pass from one process to another, the accumulated cost of output of that process is also transferred to the next process like raw material.

6. If there is WIP at the end of the accounting period, production and inventory are computed in terms of equivalent completed units.

7. If one or more products of small value emerge with the main product of high saleable value during manufacturing, they are called by-products. By-products may or may not be processed further before selling. When two or more main products with high saleable value emerge simultaneously in a process, they are called joint products.

Process Costing – Stages Involved in Processing of a Product (With Examples)

Process costing is used in case of industries, which involve processing of a product through different stages:

(i) Continuous Sequential Processing:

In case of this processing, a product has to pass through different cost centres or stages of manufacturing continuously and in succession one after the other during a period. The processing being continuous and identical, the costing units for each centre or stage are identical during any period.

Examples of this type of processing are cement-making, paper-making, refining of crude petroleum, etc.

(ii) Discontinuous Processing:

In case of this processing, a process is independently operated for the individual product as such at frequent intervals. The costing unit in case of this processing, dependent upon the product may vary even for the same cost centre.

Examples of this type of processing are dye manufacturing, fruit preservation, vegetable canning, yarn spinning, etc.

(iii) Parallel Processing:

In case of this processing, the operations or stages through which the product has to pass run-parallel and separately. All these parallel processes ultimately join with the end process.

Examples of this type of processing are manufacturing different components which ultimately join in the assembly process to make a product, meat packing etc.

(iv) Selective Processing:

In case of this processing, the combination of the processes or stages of operation depend upon the end-product to be commercialised.

Examples of this type of processing are cooked meat, chloride compounds like bleaching, powder or zinc chloride or hydrochloric acid, etc.

Process Costing – Examples of Specific Industries where Process Costing can be Applied: Production Industries, Public Utilities, Mining Industries, Chemical Industries and Others

Process Costing can be applied to mass production industries producing standardised goods on a continuous basis.

In this background, the examples of specific industries where Process Costing can be applied are presented below:

1. Production Industries:

i. Cement Industry

ii. Paper Industry

iii. Paints, Ink and varnishing, etc.

iv. Textiles, Wearing, Spinning, etc.

v. Rubber

vi. Iron and Steel

vii. Ceramics, etc.

2. Public Utilities:

i. Electricity Generation

ii. Gas

iii. Water Supply, etc.

3. Mining Industries:

i. Mineral Oil and Refineries

ii. Coal

iii. Gold

iv. Sulphur

v. Iron

vi. Gas, etc.

4. Chemical Industries:

i. Oil

ii. Soap

iii. Medicines.

5. Others:

i. Box making

ii. Distillation process

iii. Biscuit works

iv. Food products

v. Confectionaries

vi. Canning factory

vii. Coke works

viii. Meat product factory

ix. Milk diary.

Process Costing – Treatment of Important Items (With Example of Abnormal Loss and Gain)

Treatment of important items in process costing are given below:

1. Direct Expenses and Indirect Expenses:

(a) Direct expenses

All direct expenses relating to a process like material issued, labour engaged, power used etc., will be debited to the process account.

(b) Indirect expenses

Some indirect expenses are bound to incur such as – manager salary, rent of the office, departmental expenses where more than one process is carried on. These expenses will be apportioned to all processes on a suitable basis.

Generally cost of material or labour is taken as the basis to allocate indirect expenses in process costing but sometimes a more appropriate method can also be used.

2. Wastages/Losses:

i. Wastage:

Anything left as a residue after the production processes is called wastage/ loss. Wastage is generally of lesser value than the main product. It can be termed as by product if it can be sold in the market directly or after further processing. Therefore, by-produces are those residue of production process which have slightly higher value and can be sold in the market directly or after further processing.

Whereas wastage is the residue having lesser value and cannot be sold easily in the market. Sometimes residue can also be utilized again as a material in the same process or in previous process.

For instance, these are many by products in case of petroleum refineries such as – diesel, petrol, charcoal, kerosene etc. Thus in case of fabric processing, the left out portion of fabric having lesser value is an example of wastage/ Loss.

The wastage can be treated in cost accounting as follows:

a. Wastage salable in market

If the wastage can be sold in the market without further processing, the price realized from the sale should be credited to respective processes account in which wastage arise.

b. Wastage with insignificant value

Where wastage occur in different processes having insignificant value, it is better to sell wastage of all processes together and credit the amount to indirect expenses A/c or General work overhead account, so that all the processes get their share in the sale.

c. Reprocessable Wastage

If the nature of the wastage is such that it can be reprocessed in same process or in the previous process, then such wastage should be utilized again as raw material.

i. If re-used in same process

If material can be reused in the same process again, in such a case the value of wastage should be the same as that of material introduced into the process in the beginning.

If material can be reprocessed in the previous process then the value of the material will be that of the material introduced in the previous process. Thus, the wastage will be valued at the material price of pervious process. The material will be transferred to previous process account or store ledger account if kept in stores.

ii. Losses:

There are certain materials which are lost because of inherent features of material or production process, such as – evaporation, dusts, chemical reactions, inefficiencies. The wastage of material resulting from natural or inherent features of material is called loss.

In many industries there is always some losses of raw material in the manufacturing process. Thus, proper record is to be maintained for each loss.

Process losses can be divided into two categories:

a. Normal loss.

b. Abnormal loss.

a. Normal Loss:

Normal loss is a predetermined loss. It is the usual wastage of material resulting because of nature of material or process. This loss cannot be avoided. Such losses may result from the factors like chemical reaction, dust, evaporation etc. It also includes the units withdrawn for testing purposes. The cost of normal loss will be borne by the cost of good units.

Accounting Treatment of Normal Loss:

Cost of normal loss will be absorbed by the good production. So the entire cost of loss will be charged to the cost of good production. Sometimes, there may be physical loss like remaining cut pieces of iron, rubber, copper etc., i.e., resulting in physical wastage. If such wastage can be sold in the market the sale processes of such loss shall be credited in the respective process account.

The remaining loss will be borne by good production as explained below:

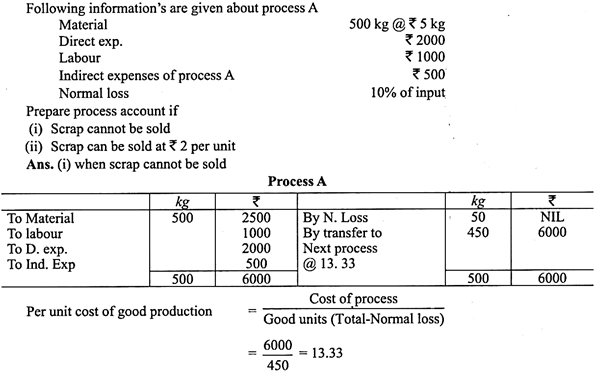

Example:

It should be observed here that though there is physical wastage of 50 units as normal loss but as it cannot be sold in the market thus entire process cost of Rs. 6000 will be borne by good production.

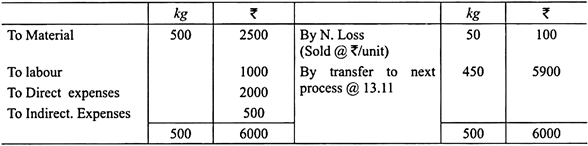

When Scrap can be sold @ Rs. 2 unit

The amount realized from the sale of normal loss Rs. 100 is credited to the process account A. The remaining cost of process i.e., 5900 is borne by good units, resulting in lower cost of production. Normal loss account can also be prepared.

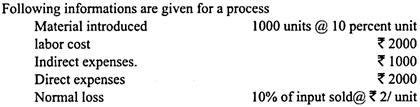

b. Abnormal Loss:

Abnormal loss means loss over and above normal loss. It results from various factors like carelessness of worker, machine break down, strike, accident, defective material or any other external factor. The percentage of abnormal loss cannot be determined in advance.

Accounting Treatment of Abnormal Loss:

The cost of normal loss should not be borne by good production; otherwise it will result in cost fluctuation of the product cost. Therefore, the cost of abnormal Loss will be credited to the process account and debited to abnormal loss account.

The sale proceeds from abnormal loss (if any) will be credited to the abnormal loss account. The abnormal loss account will be closed by transferring the balance amount to costing profit and loss account.

Thus, the cost of good units can be obtained with the help of following formula:

![]()

(a) Cost of good production = good units x cost per unit (calculated above)

Where good units = Total units introduced – Normal loss units – Abnormal loss units

(b) Abnormal loss = Abnormal loss units x Cost per unit (calculated above)

(c) Normal loss = always valued at salable value Entire process is explained with the help of example –

Example:

3. Abnormal Gain/ Effectives:

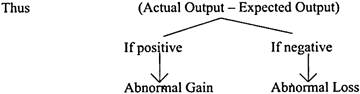

If actual good production is more than the expected good production, it will result into abnormal gain. Since normal loss can be ascertained in advance therefore, the expected output (i.e., total input-Normal loss) can also be ascertained.

But actual output may not always match with expected output. If actual output exceed expected output it will be called abnormal gain/ effective. If actual output is less than expected output it is called abnormal loss.

Accounting Treatment of Abnormal Gain:

Abnormal gain is valued in the same way as the abnormal loss. It means it is valued at the same cost of good units. The abnormal gain is debited to respective process account and credited to abnormal gain account. The balance of abnormal gain account (after adjusting normal loss) will be transferred to the costing P & L A/c

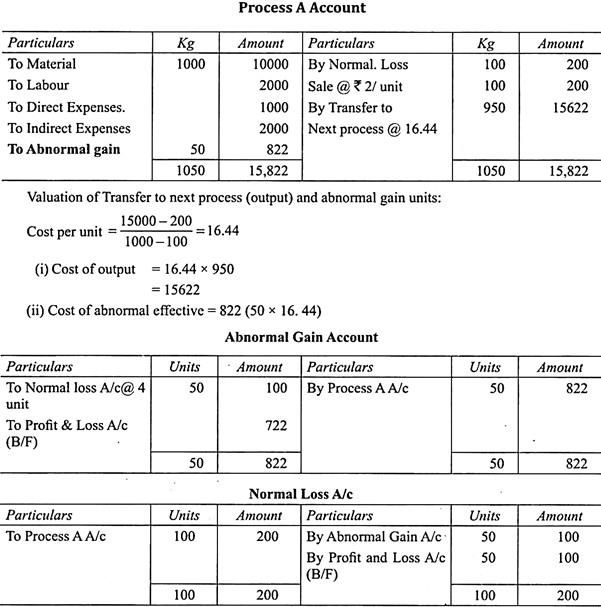

Example:

Taking information from previous example 1, total units transferred to the next process are 950 units. Prepare process A account and other accounts.

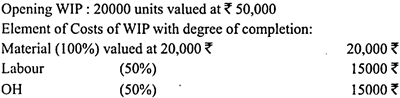

4. Process Accounts when there is Work in Progress (WIP):

Process accounting deals with the continuous production industries therefore it is quite possible that some input may remain incomplete at the end of the accounting period. That incomplete material or input is called work in progress (WIP). Valuation of semi-finished material or (WIP) presents difficulty because these units are in various stages of production or stages of completion.

WIP may include material on which work has just started to those which are about to complete. There may be same material which is 100% complete of material and labour but 50% complete in respect of overheads. Therefore, it is difficult to value work in progress.

WIP is valued in terms of equivalent production as explained below:

Equivalent Production:

Equivalent Production means conversion of semi-finished material (WIP) into completed units of production. For instance, if there are 100 units of WIP, and these are estimated to be 60% complete, then equivalent production will be 100 units x 60% = 60 units These 60 units will be taken as equivalent production and value can be ascertained for the same in process costing.

Thus, equivalent production of any WIP can be found by using following formula:

Equivalent units = Total units x Degree of Completion (%)

It should be remembered that degree of completion of WIP plays an important role. It has to be carefully determined otherwise it may lead to wrong results.

Valuation of Equivalent Production:

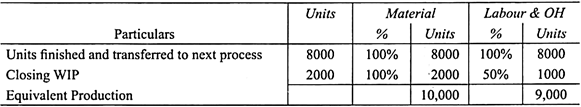

After conversion of WIP into equivalent units, three statements need to be prepared for valuation of equivalent units.

These statements are:

(i) Statement of equivalent production

(ii) Statement of cost per unit

(iii) Statement of total cost.

(i) Statement of Equivalent Production:

In this statement, equivalent production units for each element of cost like labour, material and overhead will be ascertained.

Equivalent Production units not only include converted units from WIP but also include finished output from current production as shown below:

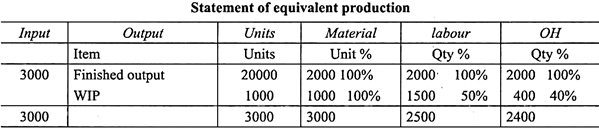

Example:

In a particular process, 3000 units were introduced of which 2000 were finished. 1000 units remain in WIP is 100% complete in respect of material, 50% and 40% complete in respect of labour and overhead respectively. Prepare equivalent production statement –

Therefore, Equivalent production units for various elements of cost are:

Material = 3000 units

Labour = 2500 units

Overhead = 2400 units.

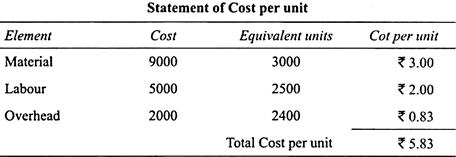

(ii) Statement of Cost per Unit:

In this statement we will ascertain the cost per unit of each element of cost like labour, material and overhead. Per unit of cost can be found out by dividing the total cost by number of equivalent units as given below –

![]()

For example, if total cost of material labour and overhead are Rs. 9000, 5000 and 2000 Rs. respectively. Then Per unit cost can be found easily. Equivalent units can be taken from previous example.

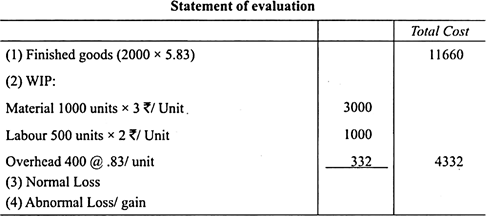

(iii) Statement of Total Cost:

In this statement, total cost of each head like finished goods, WIP, normal loss, abnormal loss etc., can be found out as given below –

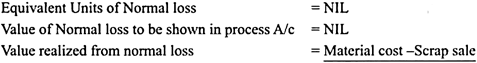

5. Equivalent Production and Valuation of Normal Loss:

We know that normal loss is incurred in various production processes. Equivalent units of normal loss will always be taken as NIL.

It means normal loss do not form part of equivalent production, therefore value of normal loss to be taken to process account will always be zero. The realizable value of normal loss (i.e., scrap sale) will be deducted from the material cost to calculate net material cost incurred.

Therefore, following points should be remembered:

i. Abnormal Loss:

Abnormal loss is over and above the normal loss. The abnormal loss will be obtained in the same way as the good production (finished output). It means abnormal loss is the loss of good production. If degree of completion of abnormal loss in respect of labour, material and overhead is not given, it is always taken as 100% complete.

Abnormal loss will be valued in the same way as good production i.e., at total cost of production.

ii. Abnormal Gain:

Abnormal gain occurs when actual production is more than the estimated production. Since it is part of good production, it is taken 100% complete in respect of degree of completion for labour, material and overheads. The value of abnormal loss will be obtained in the same way as per unit cost of good units.

However abnormal gain is deducted out of total units to obtain equivalent production. The procedure to calculate value of normal, loss abnormal loss and WIP are explained with the help of example.

Evaluation of process cost where there is opening and closing WIP both. When both opening and closing WIP are given the output completed and transferred to the next process may be obtained either according to FIFO or Average method.

iii. FIFO Method:

Under this method, it is assumed that opening stock of work in progress (WIP) is completed first before taking up new units introduced in the process. Therefore whatever remains unfinished is out of newly introduced units. The FIFO method is advisable when the prices of material are relatively stable. Use of this method will result in valuing the closing WIP at current costs.

Average Method:

Average method assumes that opening WIP is not completed first instead work an all units (Opening as well as introduced during the period) is carried on. Thus closing work in progress may not necessarily be part of recently introduced units as in the case of FIFO method.

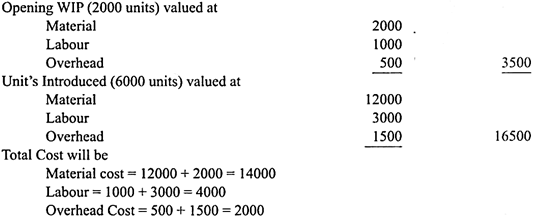

Under this method, the respective element of cost (material, labour & overhead) of opening WIP is added to total cost incurred during the period for that element of cost as shown below –

Thus, cost to be used for calculation of per unit cost will be obtained by adding cost of opening WIP and current period cost.

Under this method units completed and transferred as well as closing WIP will be valued at the average cost.

Equivalent Production will include entire units completed and transferred and equivalent units of closing WIP.

Alternate Statement of Equivalent Production:

Degree of completion of opening WIP is irrelevant here, thus statement of equivalent production can be prepared as follows:

It means opening WIP may be ignored at all as we need not to calculate value of opening stock of WIP in average cost method.

When to Use FIFO method?

Students are advised to use FIFO method when opening WIP is given in lump sum along with stages of completion of different elements of cost as given below –

When to Use Average Method?

Students are advised to use average method when stages of completion of different elements of cost are not given. The opening WIP is given in terms of material, labour and overheads instead of lump sum cost.

Example:

Use any FIFO or Average:

If both degree of completion of different elements of cost and their respective cost are given, then students are free to use any method.

Example:

Average Cost Method:

In this method, the cost of opening work-in-progress is not kept separate but is averaged with the additional costs incurred during the period. This method thus, combines the cost of opening work- in-progress and new production. Information relating to degree of completion of opening WIP is not required.

In order to find out the cost per unit of equivalent production, the cost of each element (material, labour and overheads) applicable to the opening work-in-progress is added to the cost incurred in the current period for that element. A single cumulative total and unit cost is obtained. Units completed and transferred as well as closing work-in-progress will be valued at this average unit cost.

Process Costing – Joint Products and By Products (With Accounting Treatment)

Sometimes, two or more products are produced simultaneously from a common process. If a manufacturing process using the same inputs produces two or more products, they can be either by-products; or joint products; and also major products and by-products.

The classification of the products into joint-products and by-products depends upon relative importance of the products, objectives and policies of the management etc. In the case of edible oil, which is the main product, oil cake emerges; petroleum industry gives several joint-products like gasoline, kerosene, fuel oil etc.

When two or more products of equal importance are simultaneously produced from the same raw materials, such products are generally known as joint-products. In the case of dairy industry skimmed milk, butter-cream, butter milk etc., are joint-products.

The distinction between by-product and joint-product is a matter of degree of importance of the products. It is difficult to draw a distinction, but from the accounting point of view, it is necessary.

If the products are of equal commercial importance then they can be called as joint-products and if the products are not of the same importance, then the products of lesser commercial importance are known as by-products.

The by-products are of secondary importance in terms of relative sales revenue. Generally, no additional expense is necessary on by-products, but additional expense is needed on joint-products before sale.

Joint-Product:

Joint products are the products which are jointly produced, having equal economic importance from the same or basic raw materials, possessing comparable value. For example, petroleum, diesel oil, paraffin etc., are joint-products arising from processing crude oil.

The joint-products have the following characteristics:

(a) The products are the simultaneous outcome of the joint process and from the same raw materials.

(b) The products have equal commercial value.

(c) The joint-products cannot be identified as separate products up to a certain stage in manufacturing. This stage is known as split off point. Cost prior to split off stage is known as joint-cost and cost after this split off stage is known as subsequent cost.

The cost before the separation stage has to be distributed to each product.

The accounting methods employed in costing joint-products are:

(a) Average Unit Cost Method:

In this method, it is assumed that the total cost of the process is borne by all units equally. The total process cost of pre-separation is divided by the total units produced to get the average cost per unit of production. This method is applicable where processes are common and inseparable from products and expressed in common units, i.e., weight or volume applicable to all products.

(b) Physical Units Method:

In this method the joint costs are apportioned on the basis of some physical units (raw materials) i.e., in meters, tonnes etc. Physical units are the units in which the basic raw materials are measured and are determinable at the point of separation of the joint-products. This method cannot be applied when one product is gas and another, a liquid.

(c) Survey Method (Points Value Method):

This method is adopted after a technical survey of all factors involved in the production and distribution of products. Percentage or points value is assigned to each product to denote its relative importance and common costs are apportioned on the basis of total points.

(d) Market Value Method:

In this, the joint costs are apportioned on the basis of the proportion of market price of the products. Thus, products having higher price are charged with a higher portion of the joint-costs and products having lesser price get lesser share of the joint-costs.

By-Product:

By-products can be of two types—certain products can be sold in their original condition and certain products need further processing after separation. By-products are produced along with main products and the same area of comparatively less value.

In accounts, they are treated in any one of the following ways:

i. Non-Cost Methods (Sale Value Methods):

(а) Other Income Method

The value realised by the sale of by-products is treated as other or miscellaneous income because of negligible value. The stock of by-products is valued at zero value for Balance Sheet purposes.

(b) Crediting Sales Value to the Process Account

Under this method the value of by-product is credited to the process account, so that the cost of the main product is reduced. For Balance Sheet purposes, the unsold stock of by-product carries zero value.

(c) Credit to Sales Value less Selling & Distribution Expenses

In certain cases, by-products need selling and distribution expenses, and these expenses are deducted from the sale-value. The net amount is credited to the Process account.

(d) Crediting Actual Cost to the Process

In case the by-products need further processing before sale, the amount is ascertained and deducted from the sale-value. The net amount is credited to the process account.

ii. Cost Methods:

(a) Replacement Cost

Under this method, the by-products are utilised in the same industry as raw materials and valued at the market price, the process account is credited to the value.

(b) Standard Price

In this method, the by-products are valued at standard cost (predetermined cost) and credit is given to the process account.

(c) Apportionment on Suitable Basis

Where by-products are prominent, they will be treated as joint products and as such joint-cost is to be apportioned.

Process Costing – Steps Involved in Computation of Costs

As most of the items of costs can easily be identified with, and charged to, respective process as direct costs, computation of costs under Process Costing is comparatively easier when compared to Job Costing. However, a few items of overhead expenses require the apportionment.

In this background, the costing procedure under Process Costing is summarised below in the form of steps involved in the computation of costs:

1. The production activities required to be performed in the production of a product are divided into a number of processes.

2. A separate account called, Process Account is opened and maintained for each of the processes.

3. Cost of materials, wages and other expenses are chained or debited to the Process Account concerned. As the total costs attributable to the process comprise of both the direct costs and the indirect costs, cost allocation and apportionment principles and procedure are followed.

4. Cost per unit of (finished) output of each process (i.e., Process Product) is computed by dividing the total cost incurred (for or) in the process during a period by the number of units of output produced in that process during that period.

5. As the output of a process is in the form of a semi-finished product requiring further processing, the output of one process is transferred to another (next) process. Therefore, the output of one process becomes the input for another (next) process.

While transferring the output from one process, its (accumulated) costs are also transferred to the next process.

This inter-process transfer continues till the (finished) output of the last process is obtained. This is the finished product of the company. Usually, the output of the last process is transferred to Finished Goods Account.

Process Costing – Elements of Process Costs and their Accounting Treatments: Direct Material Cost, Direct Labour Cost, Direct Expenses and Overhead Expenses

The important elements of process costs and their accounting treatments are identified and discussed below:

1. Direct Material Cost:

Raw materials required for processing are drawn from the Stores Department by the concerned process by sending Material Requisition Note. When a process uses less-than the materials received from the Stores Department, the person-in-charge of process informs the Stores Department about the quantity of raw materials consumed during the period and the quantity of raw materials left unused at the end of the period.

Based on the raw materials consumed during a period and issue prices, cost of raw materials consumed is ascertained and this is charged to the Process Account. That means, cost of raw materials consumed is debited to the concerned Process Account.

When the production of a product involves more than one manufacturing process, one can find the sequential processing of materials to obtain the finished product. In this type of situation, the output of one process becomes the input for the next process until the finished product is obtained.

While transferring the output of one process (Transferor Process) to the next process (Transferee Process), costs accumulated (i.e., not only material cost but also the conversion costs) in the first process (i.e., transferor process) are also transferred to the next process (i.e., to the transferee process).

This cost is debited to the next process (i.e., to transferee process) wherein some more or new materials are consumed. As far as the recording of these extra or new material costs are concerned, the same procedure is followed.

2. Direct Labour Cost:

Since the entire manufacturing activity is divided into a few and distinct processes, and since the employees including supervisors are posted on permanent basis to the processes, it is possible to prepare the process-wise pay-roll. Hence, the wages and salaries of employees and supervisors can be easily identified with the process concerned.

Therefore, the wage bill of all the employees working in a manufacturing process is charged and debited to the concerned Process Account.

In the case of wages and salaries of employees and/or supervisors who are assigned to work in more than one process, the same is apportioned among the beneficiary processes on the basis of the time bookings. Idle time, if any, may be accounted separately for the purpose of control.

3. Direct Expenses:

Besides the Direct Material Cost and Direct Labour Cost, many a number of items of expenses (which are charged under Job Costing as Overhead Expenses) can be identified with the processes.

Depreciation, insurance, power charges, repairs and maintenance, etc., are examples of expenses which can be directly charged to the process concerned. These expenses are, therefore, debited to the Process Account (for which these expenses were incurred).

4. Overhead Expenses:

All other manufacturing expenses which are incurred for the benefit of works in more than one manufacturing process are collected under separate Standing Order Numbers and apportioned to all the beneficiary processes on equitable or suitable basis.

Overhead expenses are normally recovered on the basis of the Predetermined Overhead Absorption Rates. The share of each process is debited to the concerned Process Account. Any difference between the overhead expenses incurred and absorbed is balanced through Overhead Adjustment Account.

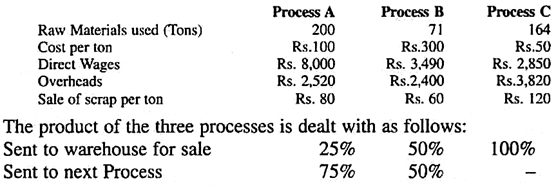

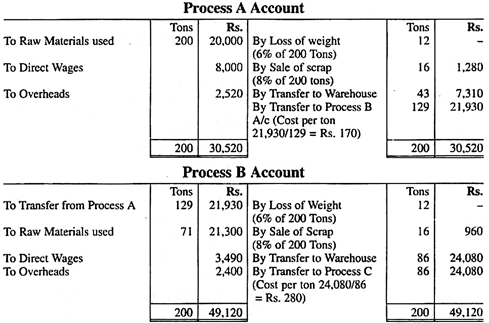

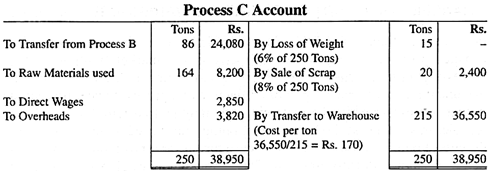

Process Costing – Transfer of a Part of Output to Warehouse for Sale (With Treatment, Illustration and Solution)

In process costing, at the time of the completion of each process, there is a finished product. It may be sold directly in the market (without further processing) or transferred to the next process as its raw material.

Sometimes, a manufacturer may transfer a part of production of a process to the next process for further processing while the remaining part may be transferred to warehouse for sale.

In such a case, both the cost of output transferred to next process and the cost of output transferred to warehouse for sale are shown on the credit side of the concerned Process Account.

The treatment can be shown by means of the following illustration –

Illustration:

The product of a manufacturing concern passes through three processes. Details of costs and production during March, 2007 were as follows –

In each process 6% of total weight is lost and 8% is scrap. You are required to prepare Process Account showing the cost per ton of each process.

Solution

Process Costing – Classification of Problems (With Formula)

Process Cost Accounts are prepared by following the procedure enumerated. However, the general and simple procedure needs slight modification and improvement depending upon the nature of the problems. For the purpose of easy understanding, the problems are classified into a few numbers of groups as presented below.

The analysis is made below taking the problems of different categories one after another:

1. Process Costing when there is no Process Loss:

When there is no loss or gain in the processing operation of a product, ascertainment of average cost does not pose any difficulty. Direct material cost, direct labour cost, direct expenses and the apportioned overhead expenses are debited to concerned Process Account. The total process costs (accumulated) are transferred to the next process along with its output for further processing.

As is known, the output of the first process becomes the input for the second process and the output of the second process becomes the input for the third process and so on ….

This process of transfer continues till the completion of the work in the final manufacturing process from which its output is transferred to Finished Stock Account. At the end of the accounting period, the unit cost is computed for each process by dividing its costs by its output.

2. Process Costing when there is Process Loss and/or Gain:

This implies that there is no difference between the number of units of raw material introduced into the manufacturing process and the number of units of finished product obtained. For instance, by introducing 1,000 kgs of raw material into the manufacturing process, if the company obtains 1,000 kgs of finished product, then there is no process loss. Because, Input 1,000 kgs = Output 1,000 kgs. But, in reality, it is very rare to find this type of situation.

Because, some loss of materials is bound to take place in the manufacturing process. The difference between the input and the output, therefore, represents the Process Loss.

If the loss is inherent to the manufacturing process, and if it is inevitable and within the limit, it is called Normal Process Loss. This type of loss cannot usually be avoided due to the nature of material and/or process.

Loss arising out of chemical reaction, evaporation, shrinkage, cutting, etc., are examples to this type of loss. On the basis of nature and type of raw materials used, nature of processing operations involved, technical aspects, etc., it is possible to anticipate the extent of Normal Loss.

Since this loss is natural and inherent to the nature of manufacturing process, the cost of Normal Process Loss shall be borne or absorbed by good units produced in the process. The normal practice is to charge no portion of process cost to normal loss. That means, the entire process cost which includes even the cost of Normal Process Loss is borne by the good units.

Hence, no separate treatment is necessary in the Process Account except entering the quantity of normal loss in quantity column on the right hand side (i.e., credit side) of the concerned Process Account. Of course, the presence of Abnormal Gain necessitates the maintenance of separate account.

However, if the Normal Loss can be disposed off for some price, then the realisable value from the sale of Normal Process Loss is credited to the concerned Process Account (i.e., recorded against the quantity of Normal Process Loss). In this type of situation, only the difference between the Cost of Normal Process Loss and its Realisable. Value is borne by the good units.

If the loss is caused by unexpected or abnormal factors such as – fire, machine break-down, negligence, inefficiency of the managerial personnel, wrong designs, substandard materials, etc., it is called Abnormal Process Loss.

This process loss is both avoidable and controllable through proper planning and management. From accounting point of view, this loss (i.e., Abnormal Process Loss) represents the excess of actual process loss over the anticipated normal process loss. On the other hand, if the actual loss is lower than the anticipated or expected normal process loss, then there arises Abnormal Gain.

Since the Abnormal Loss arises on account of inefficient operations and due to the factors which are controllable arid avoidable, it is not fair to charge the Cost of Abnormal Loss to good units. Hence, the treatment for Abnormal Process Loss in Cost Accounts differs from that for Normal Process Loss.

The following procedure is, therefore, followed to account for the Abnormal Process Loss:

i. Abnormal Process Loss is valued just like good units and transferred to a separate account called, Abnormal Loss Account,

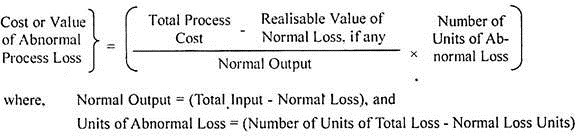

ii. Since the Abnormal Loss is valued at the same rate at which the good units are valued, the following formula is used to ascertain the cost (or value) of Abnormal Loss –

iii. The cost (or value) and units of Abnormal Loss so computed are credited to the concerned Process Account debiting the Abnormal Process Loss Account, and

iv. Abnormal Loss Account is closed by transferring the balance to Costing Profit and Loss Account (i.e., by debiting Costing Profit and Loss Account, and crediting the Abnormal Loss Account).

However, if the Abnormal Loss is in the form of scrap having some realisable value, the amount realised from the sale of Abnormal Loss is credited to the Abnormal Loss Account.

In this type of situation, the Abnormal Loss Account is closed by transferring only the balance (in the Abnormal Loss Account) to Costing Profit and Loss Account (i.e., by debiting Costing Profit and Loss Account, and crediting Abnormal Loss Account for the balance amount).

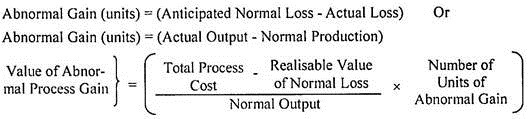

If the actual loss is lower than the anticipated Normal Process Loss, it gives rise to Abnormal Gain or Abnormal Effectives. The value of Abnormal Gain is computed using the same procedure as used for Abnormal Loss.

The Cost (or Value) of Abnormal Gain is not used for reducing the process cost. Instead, it (i.e., value along with quantity) is debited to concerned Process Account and crediting the Abnormal Gain Account.

The realisable value which would have otherwise been realised (if there was Normal Loss and no Abnormal Gain) is debited to the Abnormal Gain Account. To put it alternatively, the loss of income is debited to Abnormal Gain Account and credited to Normal Loss Account.

Abnormal Gain Account is closed by transferring the balance in the Abnormal Gain Account to the Costing Profit and Loss Account (i.e., by crediting Costing Profit and Loss Account, and debiting Abnormal Gain Account for the balance).

3. Inter-Process Profits:

As is known, the manufacturing activities are classified into a number of manufacturing processes and these processes take the form of cost centres. In some processing industrial enterprises, output from one process to another is transferred (not at cost but) at market price or at cost plus a percentage for profit.

The price at which the output of one process is transferred to another is called Transfer Price. The difference between the transfer price and the cost, therefore, represents the profit.

This profit is called Inter-process Profit as the profit is made by the transfer of output from one process to another. When the inter-departmental transfers are effected at cost plus, the processes take the form of Profit Centres.

This facilitates the company to evaluate the performance of each of the processes not only from the view point of cost effectiveness and/or economies but also by using profit based yardsticks.

Consequently, each process is expected to work more efficiently, economically, effectively and profitably to contribute its share to the overall profit, profitability, etc., of the company.

However, this system gives rise to a number of problems. One important problem relating to accounting is the valuation of closing stock of output in each process. Because, for financial statements purpose, the closing stock should be valued at lower cost or market value. But under this system of inter-process transfers at cost plus, the value of closing stock includes not only the cost element but also the profit element.

It is, therefore, necessary to eliminate the inter-process profit included in the value of closing stocks. Alternatively, cost of closing stock may be computed. At this stage, it may be of some interest to note that if the amount of profit element contained in the value of closing stock is higher than that in the value of opening stock, then the profit is overstated and vice-versa.

To compute the cost of closing stock, the following formula may be used:

![]()

With a view to ascertain the profit element included in the value of closing stock and to arrive at net realized profit for the period, three amount columns in each side of the Process Account are provided.

Further, the closing stock is shown as deduction from the debit side of the Process Account (i.e., deduction either from the prime cost or from the total manufacturing cost depending upon the valuation basis) instead of showing it on the credit side of the Process Account.

4. Equivalent Production:

One of the features of processing industries is the continuous production of goods and services. That means, production activities are undertaken by the enterprises on a continuous basis.

Consequently, one can find, at the end of the period, the units on which the manufacturing work is not complete. They are, therefore, called work-in-progress. As a result, one can find work-in- progress in one or more processes either at the beginning of the accounting period or at the end of the accounting period or both.

The presence of work-in-progress either at the beginning or at the end of the period or both poses an accounting problem as to the evaluation of period-end inventory and also about the ascertainment of cost per unit of output. This problem is solved by expressing the work-in- progress or incomplete units in terms of complete units called equivalent units of production.

Equivalent production which is also called equivalent units, effective production units or equivalent performance units refers to a systematic procedure of expressing the output or production (whether the work is completed or not) of a process in terms of completed units. It, therefore, refers to the conversion of incomplete production into its equivalent of completed units. For instance,

Computation of equivalent production is necessary for determining the cost of finished goods and that of closing work-in-progress.

The procedure for computing the cost of finished goods and closing work-in-progress involves the preparation of three important statements viz.:

i. Statement of equivalent production,

ii. Process cost sheet, and

iii. Statement of evaluation of finished goods and closing work- in-progress.

i. Statement of Equivalent Production:

This statement aims at finding out the equivalent production. In order to compute this, it is necessary to consider the degree of completion of work on opening and/ or closing work-in-progress besides the units completed and transferred.

Besides, the following points should also be kept in mind while preparing the equivalent production statement:

a. As is known, usually there is some loss in the manufacturing processes. These losses are treated in the same manner as explained already. That means normal process losses are ignored and therefore, not considered while computing the equivalent production.

Abnormal losses and gains are reckoned as good units for computing equivalent production after taking into account the degree of completion. As far as the degree of completion of work on abnormal loss is concerned, it is necessary to take the actual percentage, if given.

Otherwise, it may be assumed that 100% work, in all respects, is complete and the abnormal loss units are rejected at the end of the final manufacturing process.

However, in the case of abnormal gain (which is subtracted for arriving at equivalent production), 100% completion of work is always assumed as the gain usually denotes the finished production.

b. As far as the opening and closing work-in-progress are concerned, degree of completion of work usually differs from one element of cost to another (viz., material cost, labour cost and overhead expenses).

In this type of situation, it is necessary to apply the principle of equivalent production for material, labour and overhead expenses separately and this is called elemental equivalent production. This is necessary to compute the costs.

ii. Process Cost Sheet or Cost Statement:

This statement is prepared by considering the costs of opening work-in-progress and the costs incurred during the current period. Further, the method of valuing the transfers (such as FIFO, Average Cost Method) should also be considered.

When the normal process loss has some realizable value, it should be deducted from the material cost. The net material cost shall be divided by equivalent production in respect of material to obtain the material cost per unit of equivalent production.

Further, when a process receives transfers from other processes for further processing, material costs shall be computed properly (one, by computing material cost on the basis of the transfers from other processes and the other, on the basis of materials introduced to the process). On the basis of amounts of different elements of costs and the elemental equivalent production, elemental cost per unit is computed.

iii. Statement of Evaluation:

On the basis of equivalent production of different categories (such as – finished production, closing work-in-progress, abnormal loss or gain) and the elemental unit costs, costs of different categories of output are computed.

However, when the Average Cost Method is used, a slightly different method is followed as discussed below:

a. Under this method, degree of completion of work on opening work-in-progress is immaterial. Further, it is not shown separately while computing equivalent production,

b. Costs of opening work-in-progress analyzed into different elements of cost are added to the respective elements of costs incurred during the current period in the same process.

Besides, the cost of transfers from the previous process is also added to the material cost of the current process. Using these element-wise costs and elemental equivalent production, cost per unit of equivalent production is computed, and

c. Both the closing work-in-progress and the units completed and transferred to Finished Stock Account are valued at the unit costs computed in step (b) above.

Process Costing – Industries where Job and Process Costing is Applied (With Examples)

In a factory, both job costing and process costing methods may be applied simultaneously for different departments.

For example, in food processing industry job costing method may be applied for department mixing different ingredients by batches and process costing may be applied for manufacturing and packing departments which use the mixture and pack the end products.

Thus, it depends on the nature of the final product and processing methods of intermediate products. Again, in some industries, process costing is used in the initial process and job costing in the subsequent processing of end products.

For example, in steel industry, the cost of steel is ascertained by process costing system and cost of individual steel products is determined by job costing.

Difference between Job and Process Costing

The differences between Job and Process costing are briefly given below:

Difference # Process Costing:

1. The production is a continuous flow of stock in anticipation of demand.

2. Since the production is a continuous flow, individual identity is lost.

3. Since production is continuous there is always work-in-progress at the beginning or closing.

4. Costs are accumulated for each process for a period.

5. Costs are found out at the end of the cost period.

6. Costs are transferred from one process to another process.

7. Production is a continuous process; through standardised systems managerial control is easy.

8. Paper work is less.

9. Since production is of standard products they are uniform: similarities are there.

Difference # Job Costing:

1. Production is executed against specific order from customers.

2. The different jobs may be independent of each other.

3. Jobs may or may not have opening or closing work-in-progress.

4. Costs are accumulated for each job.

5. Costs are found out at the state of completion of the job.

6. Costs are not transferred unless there is a surplus production.

7. Since each unit is different, managerial attention is needed.

8. Since every job is costed separately, there is more work.

9. Production is on the basis of individual specification. Therefore, each job is dissimilar to others.

Process Costing – Advantages and Disadvantages

The main advantages of process costing are:

(a) Process costing helps computation of costs of processes as well as of the end-product at short intervals;

(b) Average costs of homogeneous products can easily be computed;

(c) It ensures closer control over production and costs since the daily quantitative and cost records are kept at the shop floor to assess the efficiency of production against the standards; and

(d) It involves less clerical work because of the simplicity of cost records.

The following are the disadvantages of process costing:

(a) The average cost ascertained under this method is not the true cost per unit. As such, it conceals weakness and inefficiencies in processing;

(b) If production is not homogeneous, as in the case of foundries making castings of different sizes and shapes, the average cost may give incorrect picture of the actual costs;

(c) The emergence of joint products may present the problem of apportionment of joint costs. If apportionment is not properly done, cost results may not be accurate;

(d) This system has all the weaknesses of historical costing since it based on historical costs;

(e) Valuation of work-in-progress on the basis of the degree of completion may, sometimes, be a mere guesswork; and

(f) The method does not permit evaluation of efforts of individual workers or supervisors.

Process Costing – Merits and Demerits

The Chief Merits of Process Costing are:

1. It is possible to compare the process costs periodically, say, at the end of each month. Where predetermined overhead rates are used, process costs can be computed weekly or even daily.

2. This cost finding method is simpler and requires less clerical efforts and expenses as compared to job costing.

3. Managerial control is comparatively easier as budgeted and actual figures are available for each process.

4. Average costs are easily computed, provided the product is homogeneous. Costs are accurate as allocation of expenses to process can be done easily.

5. Price quotations may be submitted without difficulty with the standardization of process. Standard costing system can be easily established in process industries.

The Demerits of Process Costing are:

1. Costs available at the end of the accounting period have only historical importance and hence are not of much use for managerial control.

2. This method gives an average cost per unit. Average cost is not of much use for detailed analysis and evaluation of operating efficiency as there is wide scope of errors. An error in one average cost is carried through all the processes. This affects the valuation of WIP and finished goods.

3. Where several products emerge from the same process, the apportionment of Joint Costs among various products becomes a problem and an element of approximation comes into picture.

4. For the purpose of valuation of WIP, its stage of completion is determined by estimation. This introduces further inaccuracies.

5. Average costs are not always accurate as the units are not fully homogeneous.

Process Costing – Multiple Choice Questions and Answers

1. Which of the following industries would most likely use a process cost accounting system?

(a) construction

(b) beer

(c) custom printing

(d) consulting

Ans. (b)

2. Which of the following is a characteristic of a process costing system?

(a) material, labour and overheads are accumulated by orders

(b) companies use this system if they process custom orders

(c) Opening and closing stock of work-in-process are restated in terms of completed units.

(d) Only closing stock of WIP is restated in terms of completed units

(e) None of the above

Ans. (c)

3. In determining production cost per equivalent unit in process costing, the average cost method considers:

(a) current process costs in addition to the cost of closing WIP

(b) current process costs in addition to the cost incurred last period which was assigned to opening WIP

(c) current process costs less the cost assigned to opening WIP

(d) current process costs only.

(e) None of the above.

Ans. (b)

4. A company’s total cost of production was Rs.50,000 in 1996; 30,000 units were completed which included 8,000 units of opening WIP (75% complete) at a cost of Rs.11,000. The closing stock of WIP was 3,000 units (l/3rd completed). The cost per unit for 1996, using FIFO method is:

(a) Rs.2.00

(b) Rs.3.00

(c) Rs.2.99

(d) Rs.1.97

(e) None of the above

Ans. (a)

5. A company had opening stock of work-in-process 3000 units, 20% completed for all items, it introduced into the process 15,000 units. At the end of the period, there was a closing stock of WIP of 6,000 units; 100% complete as to materials and one-third complete as to labour and overhead 12,000 units were transferred to the next process. The equivalent units, assuming FIFO method is used, are:

(a) 18000 for material, 18000 for labour and overhead

(b) 18000 for material, 14000 for labour and overhead

(c) 12000 for material, 12000 for labour and overhead

(d) 17400 for material, 13400 for labour and overhead

(e) 12000 for material, 15000 for labour and overhead

Ans. (d)

6. In the above example the equivalent units, assuming the average method is used, are:

(a) 18000 for material, 18000 for labour and overhead

(b) 18000 for material, 14000 for labour and overhead

(c) 12000 for material, 12000 for labour and overhead

(d) 17400 for material, 13400 for labour and overhead

(e) 12000 for material, 15000 for labour and overhead

Ans. (b)