In this essay we will discuss about:- 1. Meaning of Target Costing 2. Objective of Target Costing 3. Methodology 4. Steps 5. Implementation 6. Legends 7. Managerial Challenges.

Essay on Target Costing

Essay Contents:

- Essay on the Meaning and Objective of Target Costing

- Essay on the Target Costing Methodology

- Essay on the Steps in Target Costing

- Essay on the Implementing Target Costing

- Essay on the Legends of Target Costing

- Essay on the Managerial Challenges Faced in Target Costing

Essay # 1. Meaning and Objective of Target Costing:

ADVERTISEMENTS:

Businesses secure competitive advantage by creating superior value for customers and investors. To leverage value creation, more successful firms are adopting Target Costing.

The objective of target costing is:

“To ‘engineer-in’ targets for a product’s selling price, profit, quantity, reliability, schedule, and life cycle costs concurrently with the planning and design of the product’s features and its build process.”

Since 80-90% of a product’s potential costs are engineered in during its design, target costing provides huge leverage for value creation during the pre-production phase itself.

ADVERTISEMENTS:

Before looking at a product’s design and developing methods, in a Target costing approach, the product planning teams develop integrated evaluation of:

1. Customer preferences identified through customer ‘wants’ research,

2. Customer value adding potentials of alternative design and build possibilities, and

3. The associated product life cycle.

ADVERTISEMENTS:

In this process, the strategic goal is to optimise concurrently a product’s performance features, manufacturability, operating processes, and cycle times, along with its profits and cost targets.

Essay # 2. Target Costing Methodology:

Target Costing forces an organisation to ‘manage upstream’ during product planning and design stage and provides a framework of strategic targets to guide ‘managing downstream’ during production and later phases by employing a concurrent engineering analyses of

(i) Market forces,

ADVERTISEMENTS:

(ii) Customer needs,

(iii) Relevant technology,

(iv) Competitors’ models,

(v) Product configuration and performance features,

ADVERTISEMENTS:

(iv) Design alternatives,

(vii) Process capabilities,

(viii) Maintenance and service requirements etc., and

(ix) Life cycle costs.

ADVERTISEMENTS:

The above analyses reveal innovative possibilities in several areas, especially for:

1. Reducing cycle times for design, development, manufacturing and service;

2. Reducing costs for design, development, manufacturing and service;

3. Reducing the number of total parts;

ADVERTISEMENTS:

4. Reducing the number of unique parts per model; and

5. Reducing the rate of redesign, rework, and repair.

The end result is a product design that builds in competitive barriers and ‘guarantees’ a target profit and a target cost against a planned selling price. A new product or a derivative is approved for production only after all concerned managers are satisfied that the targets are aggressive enough and can be achieved.

Essay # 3. Steps in Target Costing :

A firm’s business plan and product-market strategies provide the framework and basic guidelines for applying the target costing methodology.

Steps involved in target costing may be summarised as follows:

ADVERTISEMENTS:

1. Determining customer wants precisely.

2. Translating them into desired product performance features.

3. Estimating the proportion of value added by each feature and component.

4. Choosing a product design that assures a targeted profit and cost targets for each component and in total.

5. Choosing manufacturing designs that assure targeted costs.

6. Choosing suppliers that assure buying at targeted costs.

ADVERTISEMENTS:

7. After each cost review, conducting value engineering to reduce target costs.

8. Monitoring initial production to ensure that all product performance/cost/profit targets are met.

Essay # 4. Implementing Target Costing:

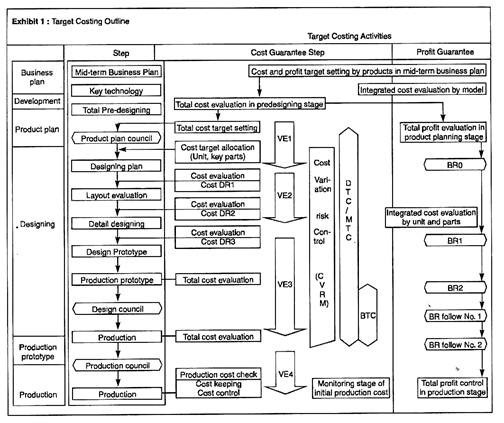

Exhibit 1(given below) provides a blue print of reengineered product development and target costing methods. The first two columns list the pre-production phases and detailed steps beginning with business plan and ending with initial production.

The next two columns list the target costing activities designed to ‘guarantee’ the achievement of targeted costs and profits.

Essay # 5. Legends of Target Costing:

ADVERTISEMENTS:

1. Cost DR1/Cost DR2/Cost DR3 = represent the series of Cost Design Reviews at three stages.

2. VE 1/VE 2/VE3/VE 4 = represent Value Engineering activities at the respective stages.

3. DTC = parts and components ‘Designed To Cost’.

4. MTC = parts and components ‘Manufactured To Cost’.

5. BTC = parts and components ‘Bought To Cost’.

6. BRO/BR 1/BR 2 = indicate ‘Business Review’ activities at respective stages.

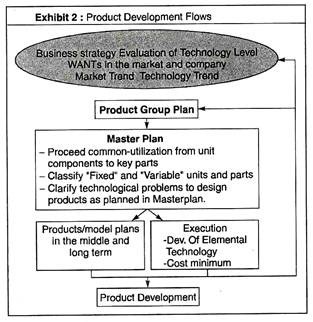

Exhibit 2 (given below) provides a linkage of product plan to company business plan through identification of ‘Wants’, ‘Technology’ and ‘Cost Minimum’.

Essay # 6. Managerial Challenges Faced in Target Costing:

Companies planning to adopt target costing must address four broad organizational issues:

(1) Aligning culture and incentives;

(2) Removing functional fixations;

ADVERTISEMENTS:

(3) Empowering cross functional teams; and

(4) Providing information support.

Target costing succeeds when the organizational culture and incentives motivate managers and employees to be sincerely committed to adding value to customers and shareholders.

This is clearly a challenge to be addressed by senior management with the help of middle management and employee participation. The objective is to make every employee driven by a two-fold passion, namely, “How can I add value to the customer?” and “How can I add value to the shareholder?”

Functional fixations are a major impediment to successful target costing. Target costing demands a profound understanding of customer needs and of the processes used to design, produce, deliver, and service the products that satisfy those customer needs.

Anchored on such knowledge, targets are set for customer value increments in each process that make up the product’s value chain. To facilitate such process oriented analysis, target costing in companies embraces process-based organizational reengineering.

Cross functional teams play a critical role in managing customer value creation in all phases, from product concept to phase out or recycling.

For instance, design and manufacturing engineers, market research staff, customer support engineers, buyers, and cost accountants collaborate on translating customer preferences to optimal product features, components, structure, and manufacturability. Team members must develop a shared understanding of the perspectives, language, and tools used by each member.

For this reason, target costing in firms empowers cross functional teams as process owners, with the functional managers providing functional support. These firms also invest heavily in cross functional training of team members.

Critical to the success of target costing is the company’s willingness to maintain an information system that has libraries of design alternatives for parts, components, and build processes along with associated cost tables.

To create such libraries, cost accountants and engineers venture beyond verifiable historical data to develop best estimates of future cost and value increments. By making such expert data readily available, the information system serves as a major source of competitive advantages.