in this essay we will discuss about ‘Materials Management’. Find paragraphs, long and short essays on ‘Materials Management’ especially written for school and college students.

Essay on Materials Management

Essay Contents:

- Essay on the Introduction to Materials Management

- Essay on the Definition of Materials Management

- Essay on the Objectives of Materials Management

- Essay on the Functions/Scope of Materials Management

- Essay on Inventory

- Essay on the Systems of Inventory Control

Essay # 1. Introduction to Materials Management:

For running any industry or business, a number of resources are needed. These resources are popularly known as 5 M’s of any industrial activity i.e., men, machines, materials, money and methods. All these resources, which are basic inputs, are important but their relative importance depends upon the particular type of industry and also other environmental factors.

Earlier, when many modern machines were not even known, whole activity was around men. But now the importance has shifted from men to machines and in the present environment, materials are the life blood of any industry or business and for their proper running, materials should be available at proper time in proper quantity at proper place.

Materials are any commodities that are used directly or indirectly in producing a product such as raw materials, component parts or assemblies. The materials require serious attention in any work of production.

Material forms the major proportion of the final product and total cost of production. Nearly 60 to 70% of the total cost of any product is because of materials. So materials offer a considerable scope for reducing cost and improving profit. An effective system of material control should be introduced to keep material costs within limits. This is possible only if a proper system of material management is introduced.

Materials management is one of the major areas covered by the process of management. The manpower in any organization is looked by personnel management. But for the efficient running of any organization, it is necessary that materials costs, its supply and its utilization are controlled in such a way which leads to maximization of profit and minimization of cost of production. Materials management covers all aspects pertaining to materials cost, materials supply and materials utilization.

Essay # 2. Definition of Materials Management:

Some of the definitions of materials management are:

Materials management involves planning, programming, organizing, directing, controlling and coordinating the various activities concerning the materials.

OR

Materials management is the management of the flow of materials into an organization to the point, where, those materials are converted into the firm’s end products.

OR

Materials management covers the whole range of functions involved in converting raw materials into finished products.

OR

Materials management is a function responsible for co-ordination of planning, sourcing, purchasing, moving, storing and controlling materials in an optimum manner so as to provide pre-decided service to the customer at minimum cost.

From the above-mentioned definitions, it is clear that materials management is concerned with effective control and management of materials right from first stage i.e. raw materials at time of procurement and up to the final stage of materials in the form of finished product.

Essay # 3. Objectives of Materials Management:

Some of the objectives of materials management are:

a. To maintain continuity of production by ensuring uniform flow of materials.

b. To minimize material cost.

c. To maintain good relationship with the suppliers of materials and also develop new suppliers for the products for which reliable suppliers do not exist.

d. To purchase the required materials at minimum possible prices by following the prescribed purchase policies.

e. To develop better relations with customers and suppliers.

f. To report changes in market conditions and factors affecting the concern.

g. To cut down costs through simplification, standardization and value analysis.

h. To supply materials of consistent quality i.e. of quality that meets user specification and is fit for service.

i. To ensure training and development of personnel employed in the department so that good industrial relations are maintained.

j. To maintain proper and up-to-date records of all stores transactions and purchases.

k. To assist technical/design department in developing new materials and products which may be more profitable to the organization.

l. To make economic ‘make or buy’ decisions.

m. To contribute in the product improvement.

n. To contribute in the development of inter departmental harmony.

Essay # 4. Functions/Scope of Materials Management:

The scope of materials management varies greatly from company to company and may include:

i. Materials Planning.

ii. Purchasing.

iii. Store Keeping.

iv. Inventory Control.

v. Receiving, Inspection and Dispatching.

vi. Value Analysis, Standardization and Variety Reduction.

vii. Materials Handling.

viii. Disposal of Scrap and Surplus, Material Preservation.

i. Materials Planning:

The function of material planning department is to plan for the future procurement of all the required materials as per the production schedule. At the time of material planning, the budget allocated for the materials will also be critically reviewed, for better control.

ii. Purchasing:

Purchasing function is one of the most critical functions as it provides the input for the organization to convert into output. Materials are the lifeblood of any organization. At the time of purchase, right quantity and quality of materials must be purchased at right time, at the lowest possible cost and select the efficient purchasing system, to derive maximum benefit. Purchase department is the unit of an organization that performs purchasing function.

The objectives of purchasing are:

a. To provide an uninterrupted flow of materials and services for company operations.

b. To find reliable alternative sources of supply.

c. To buy at the most economic order quantities.

d. To buy the best value: a combination of right quality at the best price with the best supplier service,

e. To maintain good relations with vendors.

iii. Store Keeping:

After the items are purchased, proper storage facilities must be provided so that, the wastage is reduced to a minimum. The manufacturing company appoints a person for careful storing and safeguarding materials in a store who is called storekeeper. Storekeeper is responsible for safeguarding the materials and supplies in proper place until they are required for production activities.

Storekeeping activities include:

a. Maintaining the proper record of materials relating to the receipt and issue of materials.

b. Checking the physical quantity of materials.

c. Preventing unauthorized entrance into the store room.

d. Maintaining the stock registers, entering therein all receipts, issues and balance of materials.

e. Checking and controlling losses due to theft, damage etc.

iv. Inventory Control:

Inventory control is an important function of materials management. The main objective of inventory controls is to keep the total cost associated with the inventory to a minimum. Inventory control includes deciding about the types of ordering system, fixing the safety stock limits, fixing up the reorder level and maximum/minimum stock level.

v. Receiving, Inspection and Dispatching:

The responsibility of receiving, inspection and dispatching department is to receive the materials when delivered by the suppliers. After receiving it, the quantity and quality must be checked. Production parts and materials are checked against blueprints and specifications. Non-production items are also reviewed. When once it is as per the specifications given, the goods will be accepted.

vi. Value Analysis and Standardization and Variety Reduction:

The value analysis and standardization offer greatest scope, in reducing the materials cost. It also reduces the number of varieties and also helps in finding the substitute for the materials at lesser cost.

vii. Materials Handling:

Materials handling is basically the movement of materials to various departments. Utilizing efficient handling of materials is a vital part of any industry as it provides a continuous flow of materials and reduces the stress of labour.

viii. Disposal of Scrap and Surplus Materials Preservation:

Finally the disposal of scrap and surplus must be done periodically to release the capital locked in those items.

Essay # 5. Essay on Inventory:

The dictionary meaning of inventory is ‘a list of goods’. In a wider sense, inventory can be defined as an idle resource, which has an economic value.

Inventory is a stock of direct or indirect material, from raw material to finished goods stocked in order to meet an unexpected future demand. In other words, inventory is a physical stock of goods kept for the future purposes.

In arty organization, inventory is of following four types:

a. Raw Materials Inventory.

b. Consumables and Spares.

c. Work in Progress Inventory.

d. Finished Products Inventory.

a. Raw Materials Inventory:

These may include all raw materials, components and assemblies used in the manufacture of a product;

b. Consumables and Spares:

These may include materials required for maintenance and day-to-day operation.

c. Work in Progress Inventory:

These are items under various stages of production not yet converted as finished goods;

d. Finished Products Inventory:

These are the finished goods, which are not yet sold or put into use.

Need of Maintaining Inventory:

Maintaining inventory is necessary because of the following reasons:

a. It helps in smooth and efficient running of an enterprise.

b. It helps to avoid stock-outs and shortages.

c. It provides service to customer at a short notice.

d. It helps in availing quantity discounts because of bulk purchasing.

e. It acts as a buffer stock when raw materials are received late.

f. It acts as a hedge against price increase and inflation. Since the prices of materials are consistently increasing, thus it is better to invest in inventories.

g. It provides protection against fluctuation in demand.

h. It helps in optimum use of all resources such as men, materials and machines.

i. It helps in reducing machine idle times by providing enough in process inventories at appropriate locations.

j. It helps in avoiding unnecessary wastage and blocking up of valuable working capital.

Inventory Costs:

The costs linked with inventory are:

i. Procurement Cost or Setup Cost.

ii. Inventory Carrying Cost or Stock Holding Cost.

iii. Shortage Cost or Stock Out.

i. Procurement Cost or Setup Cost:

Procurement cost includes all costs that do not vary with size of the order but are incurred each time an order is placed for procuring items.

These include costs of:

a. Receiving quotations.

b. Processing purchase requisition.

c. Follow up and expediting purchase order.

d. Receiving material and then inspecting it.

e. Processing vendor’s invoice.

Procurement cost is expressed in terms of Rs./order

ii. Inventory Carrying or Stock Holding Cost:

These are the costs incurred for carrying or holding inventory items in the warehouse.

These include costs of:

a. Money or capital tied up in inventories.

b. Storage space.

c. Depreciation and deterioration.

d. Labour.

e. Overheads (e.g., heating, lighting, security).

f. Obsolescence.

g. Theft/insurance.

Inventory carrying is expressed as percent/unit time (e.g., 10% per year) or Rs per unit item per unit time (e.g., Rs.10/item/year).

iii. Shortage or Stock out Cost:

Stock-out simply means the non-availability of the stock. These costs are associated with delay in meeting demands. This includes cost of loss of customer, loss of goodwill, loss of lagging behind in competition, loss through losing profit and incurring losses.

Essay # 6. Essay on the Systems of Inventory Control:

The following are the main inventory control systems:

(i) Fixed Order Quantity System or ‘Q’ System

(ii) Periodic Review System of Fixed Order Period System or ‘P’ System

(iii) Two-Bin System.

(i) Fixed Order Quantity System or ‘Q’ System:

In this system the order quantity is fixed for all the orders. A replenishment order of fixed size is placed when the stock level falls to the fixed reorder level. Thus a fixed quantity is ordered at variable intervals of time. EOQ is an example of the fixed-order-quantity system since the same quantity is ordered every time an order is placed.

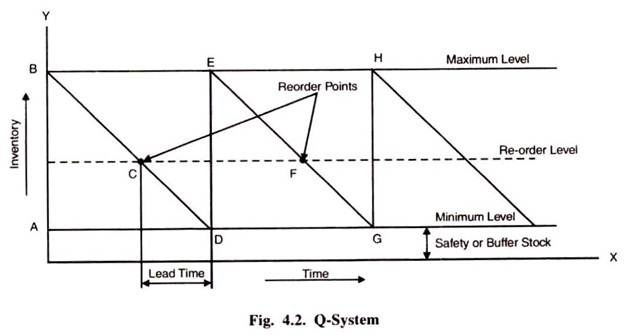

In this system reorder point is calculated, so that when the stock level touches this point, an order for predetermined number of units is placed. This system of inventory management is also called the Q-system. It is presumed that the next lot shall arrive by the time the present depleting stock touches the safety stock, keeping a stable lead time and a stable usage rate. Often called Min-Max systems, these involve both a maximum and minimum inventory level at which reorders are generated.

The Fig. 4.2 shows the working of a Q system. When EOQ is received at point A, the stock reaches point B. The stock starts consuming as the production process continues and when the stock reaches point C, then order is placed.

Advantages:

i. Each item is procured in the most economical quantity.

ii. An item is attended to only when it needs attention i.e. when its stock has reached the reorder level.

iii. Control can be exercised on inventory w.r.t. maximum and minimum levels.

Disadvantages:

i. Needs continuous monitoring of stock level of each item.

ii. This system is difficult to operate for items with unstable usage and lead time.

(ii) Periodic Review System of Fixed Order Period System or ‘P’ System:

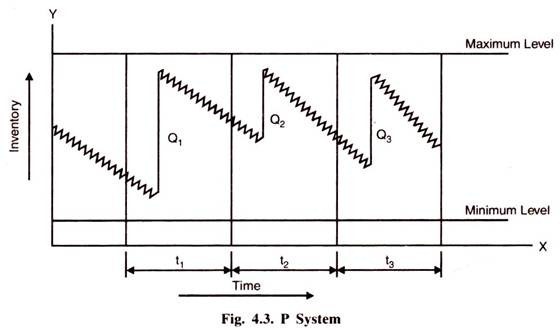

The fixed-order-period system is used when orders have to be placed at fixed time intervals such as weekly, biweekly, or monthly. Orders are placed for each item equal to the difference between current inventory level and a predetermined maximum. This system requires periodic checks of inventory levels. By this method variable quantities are ordered at fixed time intervals.

The difference between the ‘Q’ and ‘P’ system is that, in case of Q system the size of order is fixed and the time is not and in case of P system, the time after which the quantity is ordered is fixed but the size of order is not fixed.

The Fig. 4.3 shows the working of a ‘P’ system. The review intervals (t1, t2 and t3) are fixed and equal and the order quantity (Q1, Q2 and Q3) is allowed to vary.

Advantages:

i. This system is suitable for materials whose purchases can be planned months in advance and for materials which exhibit an irregular or seasonal usage pattern.

ii. This system is useful where ordering costs are small. This occurs when many different items are ordered from one source.

Disadvantages:

i. It compels periodic reviews of all items.

ii. This system is not effective to combat stock out situations.

iii. Actual ordering quantities may deviate from optimum quantity.

iv. There is no automatic trigger for reorder before the review time in the event of increased usage, which generally leads to increased inventory levels as a means of stock out prevention.

v. System does not permit effective use of economic order quantities.

(iii) Two-Bin System:

Two-bin system is an inventory ordering system in which two bins/containers of raw materials are available for use. One bin contains stock just enough to last from the date a new order is placed until it is received in inventory. The other bin contains a quantity of stock, enough to satisfy demand during period of replenishment.

To start with, the stock is issued from the first bin. When the first bin is empty, an order for replenishment is placed, and the stock in the second the is utilized until the ordered material is received. The two-bin is widely used handling low-value items.