Here is a compilation of essays on ‘Materials Management’ for class 11 and 12. Find paragraphs, long and short essays on ‘Materials Management’ especially written for school and management students.

Essay on Materials Management

Essay Contents:

- Essay on the Meaning and Definition of Materials Management

- Essay on the Objectives of Materials Management

- Essay on the Organisation of Materials Management Department

- Essay on the Duties of Materials Manager

- Essay on the Stages of Materials Management

- Essay on the Factors Responsible for Providing Economy in Materials

- Essay on the Importance of Materials Management

Essay # 1. Meaning and Definition of Materials Management:

Materials in the form of raw materials and semi-finished goods are of great significance for the success of an enterprise. These can directly affect the efficiency of a system. It is observed that irrespective of the size of an enterprise, the expenditure on materials is a major item of the budget. In many cases material consumption varies from 25% to 75% of sales turnover.

The expenditure made on materials is money invested in inventories cost of storage, transportation costs, insurance, wastage etc. Because of the magnitude of expenditures required in acquiring and controlling materials and their impact on profits, a great deal of attention is required towards the management of operations associated with materials.

While managements have long been aware of the fact that manufacturing and marketing are the two main activities of an enterprise but of late there is a feeling for a third basic economic activity known as materials management. Like manufacturing and marketing in material management also, capital is employed and costs are incurred to produce something of economic value.

Materials Management is a basic function of the business that adds value directly to the product and purchasing like plant engineering and advertising is a specialised staff activity that helps a value adder but does not really add any value to the product itself.

Essentially, materials management is the process of uniting the activities involved in the acquisition and use of materials employed in the production of finished goods products.

Some Definitions of Materials Management:

(i) ‘Materials Management’ is a term used to connote “controlling the kind, amount, location, movement and timing of various commodities used in production by industrial enterprises“.

(ii) Materials Management is the planning, directing, controlling and co-coordinating those activities which are concerned with materials and inventory requirements, from the point of their inception to their introduction into the manufacturing process. It begins with the determination of materials quality and quantity and ends with its issuance to production to meet customer’s demand as per schedule and at the lowest cost.

(iii) Materials Management is a basic function of the business that adds value directly to the product itself.

(iv) Materials Management embraces all activities concerned with materials except those directly concerned with designing or manufacturing the product.

(v) Materials Management deals with controlling and regulating the flow of material in relation to changes in variables like demand, prices, availability, quality, delivery schedules etc.

Thus material management is an important function of an organisation covering various aspects of input process i.e. it deals with raw materials, procurement of machines and other equipment’s necessary for the production process and spare parts for the maintenance of the plant. Thus in a production process materials management can be considered as an preliminary to transformation process, it involves planning and programming for the procurement of material and capital goods of desired quality and specification at reasonable price and at the required time.

It is also concerned with market exploration for the items to be purchased to have upto date information, stores and stock control, inspection of the material received in the enterprise, transportation and material handling operations related to materials and many other functions. In the words of Bethel, “Its responsibility end when the correct finished product in proper condition and quantity passes to the consumer“.

General Electric Company (G. E. C.) of U. S. A. who are pioneers in the field of Materials Management listed the functions of materials management under following heads:

(i) Planning and programming for materials purchase.

(ii) Stores and Stock control.

(iii) Receiving and issue of the material.

(iv) Transportation and material handling of the material.

(v) Value engineering and value analysis.

(vi) Disposal of scrap and surplus materials.

Essay # 2. Objectives of Materials Management:

Materials management contributes to survival and profits of an enterprise by providing adequate supply of materials at the lowest possible costs.

The fundamental objectives of materials management activities can be:

(i) Material Selection:

Correct specification of material and components is determined. Also the material requirement in agreement with sales programme is assessed. This can be done by analysing the requisition order of the buying department. With this standardisation one may have lower cost and the task of procurement, replacement etc. may be easier.

(ii) Low Operating Costs:

It should endeavour to keep the operating costs low and increase the profits without making any concessions in quality.

(iii) Receiving and controlling material safely and in good condition.

(iv) Issue material upon receipt of appropriate authority.

(v) Identification of surplus stocks and taking appropriate measures to reduce it.

The outcome of all these objectives can be listed as given below:

(a) Regular uninterrupted supply of raw materials to ensure continuity of production.

(b) By providing economy in purchasing and minimising waste it leads to higher productivity.

(c) To minimise storage and stock control costs.

(d) By minimising cost of production to increase profits.

(e) To purchase items of best quality at the most competitive price.

Essay # 3. Organisation of Materials Management Department:

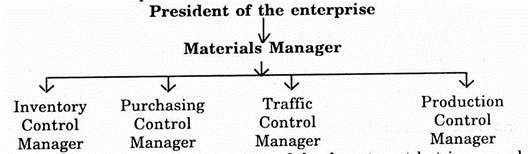

To facilitate planning, direction, control and co-ordination of various activities related to material in an enterprise there should be a separate department of materials management. The Organisational structure of the department can be,

There can be more sub-sections of the department but in general, materials manager controls the four major sections and is responsible for reporting to the president of the organisation.

Essay # 4. Duties of Materials Manager:

a. Purchasing:

Purchasing department buys materials in amounts authorised by requisitions received from the production control and stores department.

Its main operations in this context are:

(i) Selection of suppliers and issue of purchase order.

(ii) To expedite delivery of material from the suppliers,

(iii) Acting as a liaison between suppliers and other departments of the, enterprise.

(iv) To look for new products, materials and suppliers that can contribute to company’s profits.

Materials manager acts as company’s ‘eyes and ears’ to the outside world and report on changes in market conditions and other factors that can influence operations and activities of the enterprise.

b. Production Control:

This is done by:

(i) Determining requirements of materials and parts to be purchased and manufactured.

(ii) Schedules production and purchasing processes of parts and material.

(iii) Issues work order to manufacturing departments and purchase order to suppliers.

c. Inventory and Stores Control:

It keeps detailed and up to date record of inventory, on order status and potential demand for each production part and material. It is also responsible for non-productive stores like office supplies, perishable goods etc.

d. Traffic:

It controls inbound shipments of purchased materials and und shipment of finished goods to consumers.

This is done by:

(i) Selection of carriers.

(ii) Auditing invoices from carriers and filing claims for refund in case of charges or damaged shipment’s.

(iii) Developing techniques to reduce transportation costs.

e. Physical Distribution:

Finished goods are moved from the production line to the warehouse and finally to the customer.

Essay # 5. Stages of Materials Management:

The following are the main stages of material management activities in an enterprise:

(i) Decision Stage:

Co-ordination of styling, supplier development, guiding design decisions, introducing new materials and some minor changes in the production process.

(ii) Sourcing Stage:

Make or buy decision, procurement facilities etc.

(iii) Production Planning Stage:

Preparation of master schedule, calculation of material requirements etc.

(iv) Stage of Ordering:

Placing the orders, follow up, packaging and transportation.

(v) Receiving Stage:

Receiving the items, inspection of material, quality problems etc.

(vi) Inventory Control:

Determination of economic lot sizes, safety margins and inventory costs. Out of all the functions of materials management, purchasing, store-keeping and inventory control are very important to an enterprise.

Essay # 6. Factors Responsible for Providing Economy in Materials:

There are a number of ways to achieve economy in material management operations but some of them given below need careful attention and concentration:

(i) Volume of Purchases:

With large size orders the organisation have more bargaining power and less expenditure on procurement process i.e. material purchases can be done in economic quantities.

(ii) Plant Near to the Source of Materials:

In this situation transportation, inspection and some other costs are automatically reduced. This leads to economy in cost of production.

(iii) Fluctuations in Prices of the Materials:

The department of materials management should be in continuous touch with the market of the material. The purchase policy should be formulated with a view to safeguard the losses due to unforeseen and unwarranted price fluctuations.

(iv) Design and Engineering of the Product:

The design of the product should not involve complicated operations in its production process. The complex operations system generally leads to waste of material at -different stages of production process. This lead to increase in per unit cost of production.

(v) Design of Equipment:

Simple design of tools and other equipment required

to perform the operations involved in production process reduces the chances of waste and thus provides economy in production and thus provides economy in production.

(vi) Inspection of the material before placing the order and many other measures prior to actual procurement of the material leads to sufficient economy.

(vii) Some sub-parts, which are uneconomical to manufacture, can be purchased from expert and specialised agencies. This can provide economy in production.

Essay # 7. Importance of Materials Management:

Materials management department plays a vital role in the success of an enterprise. A significant portion (around 70%) of capital is invested in material and well-planned and well designed materials management operations can lead to considerable saving in the capital expenditure. It is of great importance to production, marketing, engineering and finance departments of an enterprise.

The advantages or benefits from effective materials management operations can be outlined as:

(i) Regular supply of the materials is ensured, reducing the chances of any interruption in production process.

(ii) Procurement costs and transportation costs associated with materials are checked.

(iii) Efficient store and stock control minimises waste of material.

(iv) Inspection of material at the time of procurement minimises the possibility of finished product being rejected by the consumer.

(v) Timely supply of raw-materials and other inputs can be assured.

(vi) Better utilisation of labour, capital and equipment.

(vii) Congestion in stores and at different stages of production can be avoided by an effective materials management system.

(viii) Length of manufacturing cycle is reduced to minimum.

(ix) Slight changes in material costs will exert a great impact on a firm’s profit picture.

(x) Shortages can be eliminated.

In short an effective material management can be a big asset to the organisation playing significant role in various activities of the system and providing economy in overall cost of production.