After reading this essay you will learn about:- 1. Meaning of Production 2. Methods of Production 3. Types.

1. Essay on the Meaning of Production:

Production is a sequence of technical processes requiring either directly or indirectly the mental and physical skill of craftsman and consists of changing the shape, size and properties of materials, and ultimately converting them into more useful articles.

In short we can define the production as “an organised activity of transforming raw materials into finished products.”

Production can also be defined as “producing goods which satisfy some human wants.”

Production includes manufacture of goods and services, which has four recognised factors, namely:

(i) Natural resources including land,

(ii) Labour,

(iii) Capital i.e. factory building, machinery, tools raw materials etc. and

(iv) Organisation.

Production involves a wide range of activities starting from selection of site to the packing of products for distribution.

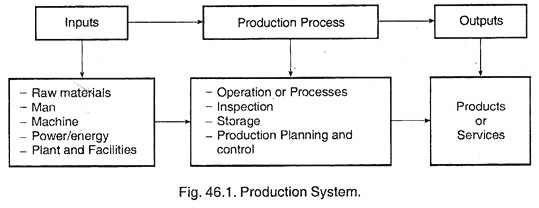

Production system consists of inputs at one end and the outputs at the other. The inputs and outputs are connected by a series of operations or processes, storages and inspections. A simple production system is shown in the following Fig. 46.1.

2. Essay on the Methods of Production:

Following are the three main methods (or types) of production:

(a) Job or Unit Production.

(b) Mass or Continuous Production.

(c) Batch or Quantity Production.

(a) Job Production:

This is the oldest method of production on a very small scale. With this method individual requirement of the consumers can be met. Each job order stands alone and is not likely to be repeated. This type of production has a lot of flexibility of operation and hence general purpose machines are required.

Factories adopting this type of production, are generally small in size (ship building is an exception). The layout of such factories is made flexible so that different type of works can be easily and efficiently carried out with the slight adjustments.

Even in this age of industrialisation many things are produced on unit production. This type of production is used for things which cannot be produced on a large scale, things of high artistic nature requiring maximum attention, like die work, boundary work etc. Man working in unit production gets an opportunity to produce large type of products and he can become expert in very short time.

Advantages:

1. It is the only method which can meet the individual requirements.

2. There is no managerial problem, because of very less number of workers.

3. Such type of production requires less money and is easy to start.

4. There is less risk of loss to the factory adopting this type of production.

5. Because of flexibility, there is no chance of failure of factory due to the reduction of demand.

Disadvantages:

1. There is no scope of commercial economy.

2. As the purchase of raw materials is less hence cost of raw materials may be slightly more.

3. For handling different types of jobs, only skilled and intelligent workers are needed, thus labour cost increases.

(b) Mass Production:

This method of production is a large scale production and is a continuous production. In the method of job production, factory works only when orders are received, and when orders are not received for some time then for that period work may come to a standstill. But mass production is a continuous production and it does not have any non-producing time.

This type of production requires specially planned layout, one-purpose machinery and costly jigs and fixtures etc. In this method with the use of automatic machines, articles automatically move forward from one stage to the next stage of manufacturing operation.

In mass production simplification and standardisation of products are made. With the help of specialised (one purpose) machines, articles of standardised nature can easily and economically be produced on a large scale.

Layout of the plant is such that it can be used for only one type of product. Sequence of flow of the product during manufacturing remains same. In this type of production different machines are assigned a definite nature of work. Throughout the run of the plant only one type of product can be manufactured.

To avoid the problem of material handling, use of mechanical means such as conveyors of different types, cranes etc. can be used.

Advantages:

1. Mass production gives better quality and increased production.

2. Wastage is minimum.

3. As raw materials are purchased on a large scale, higher margin of profits can be made while purchasing them.

4. Sales and advertising do not prove to be costly as their expenses are spread over thousands of articles produced, hence cost per unit is low.

5. Only few skilled and rest semi-skilled workers are required hence labour cost is reduced.

Disadvantages:

1. During the period of less demand, heavy losses on the invested capital may take place.

2. Because of all the machines used are one purpose machines therefore, this type of production is not changeable to other types of production.

3. Most of the workers handle only particular operation. They may get skill in their job but after some time they feel bored with the repetition of same type of work.

4. As this type of production is on a large scale, therefore it cannot fulfill individual taste. It produces things of standardised form which are demanded on a large scale.

(c) Batch Production:

This type of production is generally adopted in medium size enterprises. Batch production is a stage in between Job production and Mass production.

Batch production is bigger in scale than the Job production while it is smaller than that of Mass production. Batch production requires more machines than that of Job production and less machines than that of Mass production. In batch production some of the machines are one purpose machines and remaining are general purpose machines.

As in this type of production two or more types of products are manufactured in lots (i.e. batches) at regular interval, therefore this is known as Batch production. Most of the engineering concerns are adopting Batch production. In this type of production different products are manufactured in batches, and stocked and then sold on receipt of orders.

Advantages:

1. While comparing with mass production, it requires less capital.

2. If demand for one product decreases, then production for another product may be increased, thus the risk of loss is very less.

3. Comparing with job production, it is more advantageous commercially.

Disadvantages:

1. Comparing with mass production, cost of sales and advertisement per unit is more.

2. Raw materials to be purchased are in less quantity than that in mass production. Therefore, it is slightly costlier than that of mass production.

3. Essay on the Types of Production:

In general, we have to face two main types of manufacturing situations. Firstly, if manufacturing is done on the customer’s order, then one has to wait for the sale order before starting the manufacturing, such as industrial machinery, locomotives, power generating equipment etc.

The other situation is when the product is made to stock; the manufacturing is done without any sale order, like televisions, canned foods, electric fitting and appliances. The customer’s orders are fulfilled from the stock of finished goods.

For production control, for these two situations, we adopt two types of production:

1. Intermittent production.

2. Continuous production.

If machinery set up is used for only a short time and then changed for some other different product, this is known as intermittent production method. It consists of variety of product for short runs on the other hand if the setup of equipment is fixed and used for more time without change, this method is called as continuous production method. In this method, a standardized product is required and produced in enormous quantity.

A canning industry is an example of continuous production method where as an industry manufacturing custom made furniture, requires intermittent type of production. It must be worthwhile to note that regular working of any industry have no effect on the two types of production method.

Important Factors for Intermittent Productions:

Following are the characteristics of intermittent method of production:

1. Most of the product adopted are made in small quantities.

2. Similar types of equipment’s are grouped at one place, i.e. process layout.

3. Work load is different in different departments.

4. General purpose types of machines are used.

5. Machine operators should be highly skilled.

6. Many job instructions are needed.

7. Raw material inventories are high.

8. Method employed for materials handling are crude and non-smooth.

9. Requires more floor space, storage space etc.

Advantages:

1. Best thing of Intermittent Production is its flexibility.

2. Can accept the production of numerous orders of small quantities.

3. The cost of production is little more due to change for new product.

4. The plant layout is flexible.

5. Production delay have no serious effect.

6. Emergency rush order can be pushed more effectively.

7. In intermittent production, there is less risk due to sudden change in market trend.

8. Use of general machines cost less than special purpose machine.

9. The initial investment is less intermittent method of production.

10. Breakdown of one or two machines never creates much trouble.

Disadvantage:

The disadvantage is only when it is compared with continuous production. But continuous method requires standardization and large quantity. If both these factors are absent then the intermittent production is the only solution.

Important Factors for Continuous Production:

1. Large quantity and small variety is essential.

2. Product layout should be adopted.

3. Machine capacity and workloads are balanced.

4. Special purpose machines are required.

5. Highly skilled operators are not needed, few highly skilled operators can manufacture the total output.

6. High skill is needed behind the scenes.

7. Fewer job instructions are needed.

8. Raw material inventories are low.

9. Preventive maintenance is a must.

10. Material movement on floor is quite smooth.

11. Conveyer system can be used for material handling.

12. Requires less floor space, storage space etc.

Advantages:

1. Low unit cost is the main advantage of this method.

2. Special purpose machine initially cost more but speed up the job and cut labour costs.

3. Continuous process cuts man hours to great extent.

4. Employment of semi-skilled workers further reduces the cost.

5. There is cut in transportation cost.

Disadvantages:

1. Product changing difficulties.

2. Changes of stoppage of work due to one or two machines break-down.

3. Rigidity of output rate.

4. Less flexible in comparison to intermittent method.