Read this essay to learn about:- 1. Introduction to Manufacturing Systems 2. Classification of Goods and Services 3. Classification of Manufacturing Systems 4. Comparison.

Essay # 1. Introduction to Manufacturing Systems:

A system is composed of a number of components. These components are combined together for the accomplishment of some predetermined goal. Any manufacturing organisation can be termed as a production system to produce goods and services.

There are three main components of this system namely inputs, transformation process and output. But these components can be further divided into number of sub-components, operations and activities e.g. Inputs can be men, material and equipment.

The transformation process involves many activities and operations necessary to change inputs into output. These operations and activities can be mechanical, chemical, inspection and control, material handling operations etc. Output is in the form of goods and services.

ADVERTISEMENTS:

Thus a combination of all activities and operations to produce some goods and services is known as manufacturing system. The system depends on a number of factors viz. policies of the organisation, types of production, size of production, type of transformation process. The production method, its organisation and operation differs from company to company.

Essay # 2. Classification of Goods and Services:

The manufacturing system mainly depends upon the nature of goods and services to be produced. Goods and services can be classified into a number of categories.

Products manufactured by an organisation can be classified into two ways, namely:

(i) Purpose of the product i.e. according to definite customer’s order or to keep in stock to meet the future demand and

ADVERTISEMENTS:

(ii) Nature of the production process operations i.e., job, batch, mass and process.

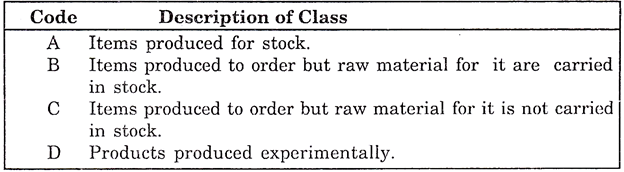

Many combinations of products are manufactured either to stock or to order by any of these operations. The classification of goods can be simplified by using different codes for each category.

Some of the commonly used codes are given below:

The production planning for the manufacturing of the product as well as for the procurement of raw materials depends upon the classification of the products. For products classified as A planning of production is based on sales forecasts only as the items are produced for stock only.

ADVERTISEMENTS:

In the case of type B items planning is done only for raw materials. The stock of raw materials inside the inventory is maintained at some pre-determined level using inventory control techniques. In the case of C type items planning is required both of production process as well as for the procurement of raw materials according to the nature and size of orders.

In the case of type B and C products, sometimes the customer makes some future commitments in advance with the enterprise, i.e. some assurance is given to purchase items monthly or at specified periods giving maximum and minimum limits of purchases each time.

In such cases the producer can plan the production schedule accordingly, manufacturing the items within some pre-determined upper and lower stock limits. Such type of products are coded as ‘BA’ or ‘CA’ indicating that the production is done to stock for duration of the contract.

Essay # 3. Classification of Manufacturing Systems:

ADVERTISEMENTS:

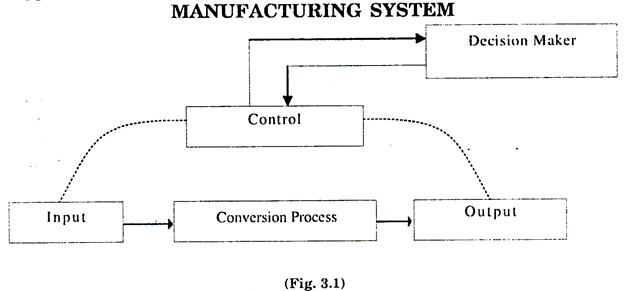

Production is the process by which goods and services are created. A typical production system is depicted in fig. 3.1.

The inputs can be raw materials, components, paperwork, etc. whereas outputs are completed parts, products, paper work output, services and scrap.

The conversion process can be characterised by following activities and operations:

ADVERTISEMENTS:

(i) Receipt and storage of raw materials – These are drawn by the production department according to such rules as FIFO, urgency, time required for delivery etc.

(ii) Means of transportation, if the system is engaged in high volume standardized production belt conveyors as means of continuous transportation are often used whereas in case of chemical plants the transportation is done through pipes or down the gravity chutes.

(iii) Inspection of in-process and finished goods.

(iv) Storage of finished goods.

ADVERTISEMENTS:

(v) The production management is active throughout by the information and control function.

The manufacturing system may therefore be viewed as an interdependent group of sub-systems, each related to its successor, each performing a different function through yet united with one other for the achievement of the overall system objectives.

It interacts both with internal and external environment. The internal environment can be a combination of marketing, accounts, personnel and finance activities. Marketing and production has a very sensitive interface and unless properly designed it can be a perpetual source of conflict between two departments due to their conflicting interests.

The external environment can be a combined effect of customers, competitors, suppliers, labour unions, stockholders, etc.

ADVERTISEMENTS:

Manufacturing systems can be classified into two categories:

a. Intermittent System

b. Continuous System.

a. Intermittent System of Manufacturing:

In this system, the goods are manufactured specially to fulfil orders made by customers rather than for stock. Here the flow of material is intermittent. Intermittent production systems are those where the production facilities are flexible enough to handle a wide variety of products and sizes.

These can be used to manufacture those products where the basic nature of inputs changes with the change in the design of the product and the production process requires continuous adjustments.

Considerable storage between operation is required, so that individual operations can be carried out independently for further utilisation of men and machines.

Examples of intermittent system are:

i. Machine shops,

ii. Hospitals,

iii. General office etc.

Chief characteristics of intermittent system are:

ADVERTISEMENTS:

(i) Most products are produced in small quantities

(ii) Machines and equipment are laid out by process.

(iii) Workloads are generally unbalanced.

(iv) Highly skilled operators are required for efficient use of machines and equipment.

(v) In-process inventory is large.

(vii) Flexible to suit production varieties.

ADVERTISEMENTS:

Planning and Control Mechanism for Intermittent System:

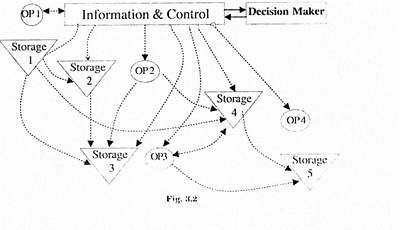

Organisation of production planning and control operations in intermittent systems needs estimation of jobs, routing, scheduling, preparation of manufacturing orders, dispatching and production control. Here customer provides the blue print and other specification regarding the product to be manufactured. Then the organisation formulates their production strategy to suit the needs of the customer.

(i) This type of manufacturing system covers specialties of every type arid sub assemblies or parts which are required to manufacture the product. Due to this there is continuous planning at each fresh order.

(ii) Due to variety of orders and different lot sizes, the system needs wise and careful sequencing of operations which makes routing and scheduling operations elaborate and complex.

(iii) Proper regulation and close inspection is required at different stages of production.

(iv) Storage facilities are to be provided at each operational stage.

ADVERTISEMENTS:

So the job of stock control of raw materials, semi-finished goods and finished goods should be entrusted to competent personnel, who can regulate the operations and flow of material smoothly.

Intermittent systems can be further classified into two categories, namely:

(a) Job production and

(b) Batch production.

(i) Job-Production:

Job or ‘make complete’ production is the production of single complete unit by one operator a group of operators e.g. bridge building, dam construction, ship building etc. Here whole project is considered as one operation and work is completed on each product before passing on to the next. Each product is a class by itself and requires a distinct and separate job for production purposes.

ADVERTISEMENTS:

The system requires versatile and highly skilled labour with high capital investments. Control of operations is relatively simple. In this system the goods are produced to definite customer’s orders. There is no assurance of continuous demand for specific items and the manufacturing depends on the receipt of orders from customers.

Job-order process is characterised by:

(i) Whole project is taken as a single operation.

(ii) Work is to be completed on each product before processing the next item.

(iii) Versatile and skilled labour is needed.

(iv) High capital investment.

(v) Control operations are relatively simple.

(vi) High unit cost of production.

Any organization manufacturing heavy and- special purpose machinery use Job-production system. The items produced in such systems are tailor made for a particular project or use and as such may be rarely or say sometimes never required again e.g. some special type of equipment required in a dam.

(ii) Batch-Production:

Here the production schedule can chalked out according to specific orders or on the basis of demand forecasts. The items are processed in lots or batches unlike job-type system where one item is produced during each production run. In batch-type system new batch is undertaken for production only when the work on all items of a batch is complete. In fact batch type production can be considered as an extension of Job- type system. Prof. Druncker has given a single name “unique product production” to job and batch type of systems.

In the system of batch production, any product is divided into parts or operations and that each operation is to be completed throughout the whole batch before the next operation is undertaken. In other words, here after the production of one batch, the plant and machines become available, to other batch of similar type of production. One can employ more specialized labour for each operation with comparatively low investment.

But organization and planning is more complicated in this system. It is characterized by the irregularity in the increase of work added to the basic material. The best example of batch production system is of chemical industry, where different medicines are manufactured in batches. Other examples can be, production of electronic instruments, machine tools, printing press etc.

In this system a batch is not passed to next operation until the work on the previous operation is complete for the whole batch and no new batch enters the production line, till all the operations for manufacturing any product are completed. This results in considerable idle time for various operational centres.

A common characteristic of Job-Batch systems is that items are produced to definite customer orders and not for stock. There appears to be no significant deviation in planning and scheduling processes in both these systems. In general diagrams are used for functions, rectangles for documents and solids for raw or semi-finished goods.

Here production planning is not based on sales forecasts but one has to estimate or evaluate the requirements on the basis of general business conditions, past information and future sales promotion programmes of the organization.

In a Job/Batch System on receipt of orders, these are placed on load chart. Once the orders are received, production-scheduling operations begin. Here the schedules are not prepared in advance. Similarly no advance planning and scheduling is done for procurement of raw materials in these systems. The systems working starts only on the receipt of orders from the customers.

Features of an Intermittent System:

(i) Demand can be discontinuous.

(ii) All operational stages may not be balanced.

(iii) Elaborate sequencing and scheduling is required.

(iv) Needs high investment.

(v) Planning, routing and scheduling changes with fresh orders,

(vi) Storage is necessary at each stage of production process,

(vii) Can adjust to new situation and specification,

(viii) Inspection is not in line with production,

(ix) Items are manufactured according to order.

b. Continuous System of Manufacturing:

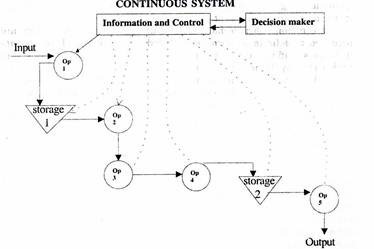

In this manufacturing system the items are produced for the stocks and not for specific orders. Before planning manufacturing to stock, a sales forecast is made to estimate likely demand of the product and a master schedule is prepared to adjust the sales forecast according to past orders and level of inventory.

Here the inputs are standardized and a standard set of processes and sequence of processes can be adopted. Due to this routing and scheduling for the whole process can be standardized. After setting of master production schedule, a detailed planning is carried on. Basic manufacturing information and bills of material are recorded. Information for machine load charts, equipment, personnel and material needs is tabulated.

In continuous manufacturing systems each production run manufactures in large lot sizes and the production process is carried on in a definite sequence of operations in a pre-determined order. In process storage is not necessary which in turn reduces material handling and transportation facilities. First in first out priority rules is followed in the system. In short, here the input-output characteristics are standardized allowing for standardization of operations and their sequence.

Production Control Mechanism for Continuous Manufacturing system:

In this system the control mechanism is not as elaborate and complex as for intermittent system. In continuous system large quantities of standardized products are produced using standardized production process.

Following points of control mechanism are worth noting for such a system:

(i) This system does not involve diverse work, due to which routing standardized route and schedule sheets are prepared.

(ii) In case of standard products meant for mass production, master route sheets are prepared for more effective co-ordination of various departments.

(iii) Scheduling is required to rate the output of various standard products in their order of priority, operations and correct sequence to meet sales, requirements.

(iv) Work relating to dispatching and follow-up is usually simple.

Dispatch schedules can be prepared well in advance in such systems.

Continuous system can be divided into two types of production, namely:

(i) Mass sand

(ii) Process production.

(i) Mass Production:

Standardization is the fundamental characteristic of this system. Here items are produced in large quantities and much emphasis is not given to consumers orders. In fact the production is to stock and not to order. Standardization is there w.r.t. materials and machines. Uniform and uninterrupted flow of material is maintained through predetermined sequence of operations required to produce the product. The system can produce only one type of product at one time.

These days, mass production system is generally used to manufacture sub-assemblies or particular parts/components of an item. These parts are assembled together by the enterprise to get the final product. One distinct advantage of this approach is that different combinations of sub-assemblies or parts can be used to manufacture different kinds of products. Specialisation and standardisation in manufacturing single component also leads to economies in production and product diversification to meet specific demands of consumers.

(ii) Process Production:

This system is analogous to Mass production system with more stress on automation in production process. The volume of production is very high. This method is used for manufacturing those items whose demand is continuous and high e.g. petroleum products, particular brand of medicines, heavy chemical industries, plastic industries etc. Here single raw material can be transformed into different kinds of product at different stages of the production process e.g. in processing of crude oil in refinery one gets kerosene, gasolene etc. at different stages of production.

In mass and processing systems planning and scheduling for materials and finished products is done well in advance. The loading chart gives information about the availability of adequate equipment. The requirement of labour and equipment to produce desired quantity of items is known in advance and knowing the plant capacity, planning can be done for arranging shifts system. The procurement schedule can be also be planned in advance.

Production control operations are done during the production process. Minor adjustment can be done in case of emergency. The whole system is designed to produce some specific type of product only.

Features of Continuous Type of Manufacturing Systems:

(i) There must be continuity of demand.

(ii) The product must be standardised.

(iii) Material should be per specifications and delivered in time.

(iv) All operational stages in the process must be balanced.

(v) Work must conform to quality standards.

(vi) Appropriate plant and equipment must be provided.

(vii) Maintenance must be by anticipation and not by default.

(viii) Inspection must in line with production.

Advantages of Continuous Type of Manufacturing Systems:

(i) Direct labour content is reduced.

(ii) High accuracy.

(ii) Work in progress is at a minimum.

(iv) Storage at different stages of operation not necessary.

(v) Reduced material handling.

(vi) Control process simple.

(vii) Any weakness in the system is easily located.

(viii) Material requirements can be accurately planned.

(ix) Investment in material can be more rapidly translated into income from sales.

Essay # 4. Comparison of Various Manufacturing Systems:

Different systems of production can be compared in terms of following characteristics:

1. Manufacturing Costs:

Per unit cost is maximum in Job production and minimum in process production. The four methods of production in increasing order of costs can be arranged as process, mass, batch and job.

2. Capital Investment:

The requirement of capital varies according to the nature of the product and the input needs. The systems in ascending order of capital investment can be arranged as job, batch, mass and process.

3. Size of Plant:

In job and batch system same equipment/machine can perform a number of operations to manufacture different type of items. So the size of the plant is likely to smaller than those for mass and process system where whole production process is to be strictly arranged in a predetermined sequence of operations.

4. Technical Requirements:

Highly skilled labour is required in job and batch production to operate and carry out specialized work on machines. In the case of mass and process systems semiskilled persons can also operate the machines. But due to large scale of production, more managerial skill is required in continuous systems.

5. Organisational Structure:

In job and batch production generally functional organisational approach is adopted whereas divisional organisation pattern is used in mass and process systems. There is decentralisation concept in organisation of job and batch whereas centralisation is prominent in mass and process systems.

6. Flexibility in Production:

Job-batch systems can easily adjust to changes in the requirement of the consumer with incurring any heavy expenditure. But in the case of mass and process system we can produce one single product and with change in demand of products the systems cannot be adjusted easily. Thus job-batch system using general purpose machines is more flexible than mass-process system using single purpose machines.

7. Type of Products Produced:

Job system can be used in buildings, bridges; specific machines production etc. and batch system can be used in producing machine tools, garments, shoes etc. Mass production is useful for production is useful for producing electrical items like switches, plugs, refrigerators etc., cars, trucks, tractors etc. Process production is suitable to manufacture petroleum, dairy and chemical products.

8. Security of Job:

Job and batch systems produce items only when orders are received. During slack periods when there is no or very little demand workers are likely to sacked. Thus there is less job-security in Job- batch systems. In mass and process system, items are manufactured for stock and so production is continuous. Due to this there is more job-security for workers.