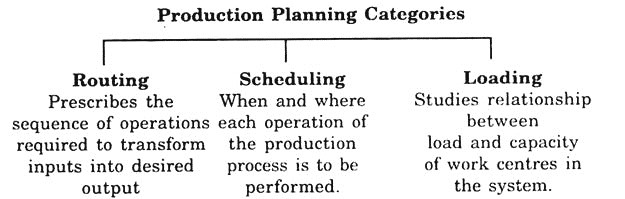

Read this essay to learn about the top three techniques used for production planning in an organisation. The techniques are:- 1. Routing 2. Scheduling 3. Loading.

Essay # 1. Routing:

“Routing means determination of path or route over which each piece is to travel in being transformed from raw material into finished product.”

Evidently where one single product or part is manufactured by a fixed set of machines. The job of routing becomes mechanical. In continuous manufacturing systems with fixed line layout, if needs no managerial effort for routing, though different sets of machines are used in manufacturing the products in such systems.

But in intermittent type of systems routing is a complex task when different kinds of products are to be manufactured. Routing of a production order contains a complete description of the item to be manufactured, details of each operation involved in the process, the setup time and the standard time required to complete the work. It also determines the type of machines needed to perform each operation and also alternative machines in case of emergency.

The precedence of various operations involved in the process is also prescribed. Here various operation involved in the process is also prescribed. Here for every item or batch of production the production process should be outlined on different route sheets. Routing also prescribes the amount of material, types of equipment and machines and the number of skilled and unskilled workers required to perform a particular job or operation.

Actually routing is the basis for scheduling and loading. In the words of Sprigal and Lansburg, “Routing includes the planning that where and by whom the work shall be done. It determines the path that work shall follow and prescribes the sequence of operations. It forms the basis for scheduling and functions of planning“.

In general routing consists of seven decisions, namely:

(i) Whether to make/buy.

(ii) The form and shape of the material.

(iii) The division of work to be done into operations.

(iv) The choice of machines/work centres on which each operation should be done.

(v) The sequence in which operations are to be performed.

(vi) The division of operations into work elements.

(vii) The choice of special tooling.

Routing consists of following steps:

(i) The product is fabricated into sub-components to decide that which components can be produced inside the plant and which parts are to be purchased from outside i.e., to manufacture or out-source i.e. to buy decision is made.

(ii) The decision that which components can be manufactured by the organisation will determine the requirement of inputs i.e. material, labour etc. The production process of transforming inputs into output is then outlined in the form of drawing as a route sheet using different symbols and notations for identification. Preliminary test can be made to ascertain the amount of inputs actually required to produce the desired output.

(iii) The next step is to determine various operations involved in the, transformation process and then to list the sequence of these operations on the route sheet.

(iv) The duration and the nature of equipment and machine required for each operation is determined.

(v) The economic lot size of production order quantity is calculated.

(vi) The amount of waste which depends on the scraping factors is estimated.

(vii) The various types of proformas to record the details of production process at different stages of production are also designed. The format of these proformas depends on the type of manufacturing system.

It can be observed from the steps outlined above that routing mainly depends on the nature of manufacturing system, availability of plant equipment and its component parts, human resources etc.

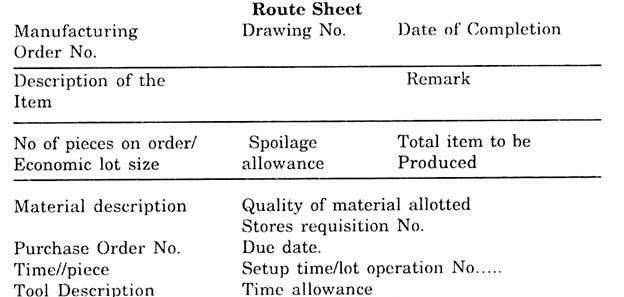

In a manufacturing plant, the routing of an order is generally spelled out on route sheets. There is great similarity between route sheets and operation process charts. A route sheet contains a complete description of the item to be manufactured, the details of each operation required in manufacturing process, the setup time and standard operation time etc.

The route sheet also specifies the machines to be used and the possible alternatives wherever feasible. Route sheet also provides the sequences of various orders as well as the best/optimum sequence for the desired, operations taking into consideration the resources available.

The following points should be kept in mind for drawing route sheets:

(i) The machines are to be operated at full capacity.

(ii) The product passes through those work centres, which are manned by best possible personnel.

(iii) The route is shortest and most economical.

(iv) The person solving routing problem should be well acquainted with various operations.

A specimen of route sheet is given below:

Advantages of routing are:

(i) Efficient use of available resources.

(ii) Reduction in manufacturing costs.

(iii) Improvement in quantity and quality of the output.

(iv) Provides a basis for scheduling and loading.

Essay # 2. Scheduling:

The next technique used for production planning is scheduling. Scheduling is the process of prescribing ‘when’ each operation in a production process is to be executed. In other words it involves designing the time table of manufacturing activities indicating the time required for the production of units at each stage.

According to Sprigel and Lansburg, “Scheduling involves establishing the amount of work to be done and the time when each element of the work will start“, in the words of Kimball and Kimball, “The determination of time that is required to perform each operation and also the time required to perform the entire series as routed is scheduling“.

Thus scheduling can be termed as:

(i) A description of when and where each operation in a production process is to be executed.

(ii) Establishment of timetable at which to begin and/or complete each, event or operation comprising any procedure.

Objectives of Scheduling:

The fundamental objective of scheduling is to arrange the work of the production unit in such a way that (i) items are delivered on due date and (ii) the production cost is minimum.

In general scheduling may be carried out to meet following objectives:

(i) To plan the sequence of work such that delivery date is met.

(ii) To have minimum throughput time for having better utilisation of resources.

(iii) To minimise idle time of machines, labour etc. for having maximum utilisation of plant and reducing the cost of wages.

(iv) To prevent unbalanced allocation of time among various departments and work centres.

Classification of Schedules:

I. Operation Schedule:

Operation schedule determines the total time required to do a piece of work with a given machine or process. It indicates the time required to perform as well as other details of type of materials, machines, labour etc. required for each and every operation.

II. Master Schedule:

Master Schedule is a list showing how many of each item to make in each period of time in future. These are usually changed as time moves along in response to change in conditions. It is first step towards planning for Production. Here on the basis of sales forecast and levelling of production, the quantities to be produced are determined.

It is initially based on the released and planned orders and is then refined by the iterative process with the use of flow charts. After finalizing master schedule each customer’s order can be verified for the proposed delivery date and the promises made.

The nature of master schedule depends on whether the manufacture is to order or to stock. When the products are made to customer’s orders, the job of master schedule is largely to look out at the future work load of orders already on hand and seeing the date of delivery desired by the customer to fix the date of delivery i.e. one must know approximately, how many man-hours work load is already there in each major department.

It is also necessary to pay attention to the sequence of workloads in different departments. If an item needs to be designed, the engineering workload will have to come early. Unless the work load needed in the early stage departments can be handled on time the work in later stage departments will be delayed even if they have open time earlier.

The development of a master schedule for manufacture to stock begins with a sales forecast. In such cases one of its major function is to smooth out the differences as much as possible between regular sales and steady production largely by inventories to cushion the differences.

III. Sequential Scheduling:

A best or optimum schedule can rarely be recognized, even assuming the optimum to be known. Here the problem is to define a sequence for a multi-product plant, which pass through a number of departments. If the sequence is varied in each department the number of sequences will increase and there is no known technique to identify the optimum sequence even assuming that; the optimum can be explicitly defined.

If the duration of each operation is known then two general rules for finding the optimum sequence can be:

(i) For minimum time lost each operation should be longer than any predecessor in a programme.

(ii) For minimum individual lead time each operation should be shorter than any predecessor in a programme.

Scheduling Devices:

Scheduling can be considered as a typical queuing problem with following criteria:

i. Each job joins the end of the queue with first in first out priority.

ii. Job with the longest duration always goes first.

iii. Jobs may be ranked according to earliest delivery date.

The schedules based on above criteria can be prepared with the help of following techniques:

i. Gantt Charts.

i. CPM and PERT techniques.

iii. The Run out approach.

i. Gantt Chart:

These charts portray planned production and actual performance over a period of time for any or all of the factors that require planning and control. It is a rectangular chart divided by parallel horizontal and vertical lines.

Some other type of charts viz. machine record charts showing the available machines and the time at which various jobs are planned, order charts indicating the time to start various orders and the time of completion can be used for scheduling.

ii. CPM and PERT Method:

Critical Path Method (CPM) Project Evaluation Review Techniques (PERT) based on network analysis have become powerful scheduling devices. Here the job is first broken into basic elements and a network is constructed. The network is then analysed to prepare the schedule.

iii. The Run out Approach:

This method is applicable to production that is geared up-to inventory level. It is demand oriented and tries to minimise stock outs by assigning highest priority to items most in danger of running out. The run out time for each product is calculated and a monthly forecast for future monthly usage is developed.

Finally the number of months that may elapse before the inventory will run out is calculated by subtracting the monthly forecast from the total inventory. The method is easy, quick and inexpensive. It also minimises stock-outs and helps to improve the consumer service.

V. Comparison of Routing and Scheduling:

Both routing and scheduling are important techniques of production planning. Routing provides the best and the most economical production sequence, whereas, scheduling prepares a logical time-table showing the starting and finishing time of each production work in accordance with some pre-determined programme. In the words of Stanley Vance, Routing Considers the ‘where’ aspect and scheduling ‘when’.

Essay # 3. Loading:

Another important technique of production planning is loading. In planning the production process the management-must know when a particular equipment/machine will be available for work on each order or item. For this information a list of the number of machines capable of performing similar operations is prepared.

Knowing the number of machine shifts available for each kind of operation and number of shifts required for such operations in the production process to complete the schedule, the planning staff can evaluate whether the work load is greater or less than the capacity of the equipment.

Loading does this. ‘Loading can be defined as the study of the relationship between load and capacity at the places where work is done. Loading and scheduling are designed to assist in the efficient and systematic planning of work.

Loading provides complete and correct information about the number of machines available and their operating characteristics such as speed, capacity, capability etc. This information can be used to calculate the difference between work load and actual capacity and then to determine whether customer’s order can be completed on due date or not.

I. Objectives of Loading:

The following are some of the main objectives of Loading:

(i) To plan new work orders on the basis of spare capacity available.

(ii) To balance the work load in a plant.

(iii) To maintain the delivery promises.

(iv) To check the feasibility of production programmes.

II. Loading Devices:

There are two main approaches for loading viz. loading step by step, and machine loading and load charts:

A. Loading Step by Step:

Sometimes an individual production order may require a finite number of operations and the order of these operations may vary too much from item to item. In such cases overloads are scheduled to account for interaction among various operations by identifying the operation which imposes maximum delay on the order.

Following are the steps in this approach:

(a) Find the earliest date and the hours required that can be scheduled onto each operation.

(b) Determine the hours required at each operation and the time thereafter to complete the job if no loading delay occurs.

(c) Schedule the bottleneck operation as early as possible.

(d) Schedule subsequent operations as early as possible.

B. Machine Loading:

Using information from schedules, weekly/periodic load in hours is determined for each machine and is then recorded on machine load chart. The chart also gives the time for which the machine is busy for parts pertaining to different work orders.

A machine load chart for all the machines in a production department shows the future spare capacity of machines. The machines should be loaded to full capacities as idle capacities of machines are sources of loss to the organisation and also increase the cost of production.

C. Load Charts:

Load charts shows the work assigned to various departments, machines or components of an organisation.

During “periods of peak/heavy loads information from load charts can be used to Determine”:

(i) Priorities to future orders and to decide whether to subcontract or refuse new orders.

(ii) Provision of overtime or multi-shift operations.

(iii) Acquisition of extra men or equipment for additional capacity.

One common procedure for Loading is to maintain a register at each machine center. When any order is loaded on a machine a entry is made in the register showing the estimated time, the order is likely to devote on the machine and the estimated time off. The information can also be presented with the help of Gantt chart.