After reading this essay you will learn about:- 1. Meaning of Purchasing 2. Functions of Purchasing Department 3. Duties of Purchasing Officer 4. Classification of Purchases 5. Objectives 6. Specifications 7. Procedure 8. Principles 9. Methods.

Essay Contents:

- Essay on the Meaning of Purchasing

- Essay on the Functions of Purchasing Department

- Essay on the Duties of Purchasing Officer

- Essay on the Classification of Purchases

- Essay on the Objectives of Purchasing

- Essay on the Specifications of Purchasing

- Essay on the Procedure for Purchasing

- Essay on the Principles of Purchasing

- Essay on the Methods of Purchasing

Essay # 1. Meaning of Purchasing:

Purchasing is the activity responsible for getting the right material to the right place at the right time in the right quantity at the right price.

For an Organisation, purchasing (procurement) is that function which is responsible for that phase of the material cycle, from the time an item is requisitioned until it is delivered to the user. This includes the selection of vendors, deciding the price and negotiating for quality and delivery. It also coordinates for transportation, receiving, inspection and inventory control.

In any workshop or industry purchase means buying of equipment, materials, parts, tools, stores etc. required by industry. As one of the first acts of manufacturing business is to purchase materials, hence purchasing is a primary function. Competitive sales cannot be made unless the material used for manufacturing or for resales, are purchased at ultimate cost which is commensurate with that available to competitors.

The importance of the purchasing function varies with the nature and size of industry. In small factories, this function is performed by works manager but in large manufacturing concerns, where large quantities of materials are consumed, the buying function is given to a separate department under highly competent executive designated as chief buyer or purchase manager or purchasing officer.

The costs of direct and indirect materials form a part of the prime cost of the product. Careful buying helps in reducing the cost of materials and thereby increasing profits. Hence purchasing is one of the delicate activities and the persons employed should be sincere, honest and intelligent.

Essay # 2. Functions of Purchasing Department:

1. To purchase materials on properly authorised requisitions.

2. To place orders of the requisitioned goods with right suppliers.

3. To obtain right type and quality of goods at cheapest price.

4. To purchase right quantities in right time.

5. To see those deliveries of all goods are received within time.

6. To check and see that the goods received are in accordance with the orders placed in respect of quality, quantity and specifications.

7. To advice the management regarding possible economics to be maintained by manufacturing an item instead of purchasing or >vice-versa<.

8. To study the market conditions enter into a rate contract with the large suppliers to ensure availability of materials all the time.

9. To study the various sources of supply and decide the most convenient as well as alternate supplies.

10. To maintain the list of available and reliable suppliers.

11. To keep the list of articles needed in the organization up to date with their normal quantities for placing orders.

12. To prepare specifications to obtain quotations and compare these quotations and placing orders.

13. To ensure that supplier’s payments are made promptly so that better relations are maintained.

14. To purchase directly all small items, which do not require quotations?

15. To consider first the interest of the enterprise.

16. To assist purchasing agents, co-operate all, raise the development and purchasing standards.

Essay # 3. Duties of Purchasing Officer:

The most important and essential duties of purchasing officer are:

1. To maintain the standard of quality of product by selecting right quality of materials during purchases.

2. To organise and direct the purchasing department for efficient working.

3. To represent his concern with other concerns during purchasing contracts.

4. He should maintain the reputation of the concern through integrity and fair dealings with others while negotiating.

5. Shops should not wait for materials.

6. To make a final check on all the requisitions received from different shops in the interest of economy, as regards quality, quantity and specifications.

7. To help in the preparation of purchasing budget.

8. To spend money on purchases very carefully and wisely.

9. To suggest if the materials can be economically produced in the concern instead of purchasing and vice-versa.

Essay # 4. Classification of Purchases:

In a manufacturing industry the purchases can be classified as under:

1. Raw materials,

2. Component parts, assemblies or sub-assemblies,

3. Consumable stores or supplies,

4. Office supplies i.e., stationary etc.,

5. Spares,

6. Tools, and

7. Machines and equipment.

Essay # 5. Objectives of Purchasing:

A. From a Top Managerial Perspective:

The management expects the purchase department to achieve the five rights in the acquisition of materials.

Five rights are:

1. Right quality.

2. Right supplier.

3. Right quantity.

4. Right time.

5. Right price.

A sixth factor implied in these items includes the desired services necessary for optimal supply and utilisation of materials.

B. From an Operating or Functional Perspective:

1. Uninterrupted flow of materials and services.

2. To buy competitively.

3. To buy wisely, which involves a continuous search for better combination of quality, services and price relative to the buyer’s needs?

4. To keep inventory investment at a practical minimum.

5. To keep inventory losses at a practical minimum.

6. To develop effective and reliable sources of supply.

7. To develop and maintain good relationships with the suppliers.

8. To achieve maximum integration with other departments of the firm.

9. To handle the purchasing function in a professional and cost-effective manner.

Essay # 6. Specifications of Purchasing:

Specifications play an important role in the search for the right quality and the right value. They also assist in resolving the design conflicts which exist between engineering, manufacturing, marketing and procurement.

Purchase descriptions directly affect the quality and performance of the item purchased and the payment. Specifications are the detailed method of describing requirements. These are the descriptions that tell the seller exactly what the buyer wants to purchase.

As costs of materials depend upon their specifications, which ultimately determines the cost of product. Describing the material’s specification during design stage is the first point at which numerous costs can be reduced and controlled. The right specifications are those that blend the requirements of all the departments. Specifications developed must balance product quality characteristics and product cost.

Methods of Describing Specifications:

Following methods are generally used for describing specifications:

1. Design Specifications:

For items which are not covered by standard specifications or brands, specifications are prepared by buying firms with the aim to broaden their field of competition. By preparing its own specifications, a company can avoid the premium prices of brand name items and the sole-source problems.

2. Drawing:

Where precise shapes, dimensions, and special relationships are required, drawings are the most accurate method of describing.

3. Material and Method of Manufacture Specifications:

In this method prospective suppliers are asked as to what specific materials to be used and how they are to be processed. This method is however, not very common.

4. Performance Specifications:

Performance specifications describe in words and quantitatively where possible, what the item is required to do. In this method potential suppliers are told only the performance that is required. These are used to buy expensive, complicated machines and machine tools.

5. Brand or Trade Names:

A brand represents the manufacturer’s pledge that the quality of the product will be consistent from one purchase to next. Brand name products are among the simplest to describe on a purchase order, and save purchasing time and reduce purchasing expense. Inspection expense is also low for branded products. The prices for such products are usually higher.

6. Samples:

When samples are used, the buyer is not required to look for an equal brand or describe the performance wanted or pick a standard specification. It is generally difficult to determine by inspection that the product delivered is, in fact, the same as the sample, and therefore, acceptance, or rejection becomes a matter of subjective judgment.

Essay # 7. Procedure for Purchasing:

For a medium industry following purchasing procedure is generally adopted, although slight variation can be there depending upon the circumstances:

1. After receiving the purchase requisition forms, exact quantity of material to be purchased and its specification is decided.

2. Prepare a list of suppliers who deal with the business of the articles to be purchased and are reliable.

3. If the material to be purchased is of small amount and required urgently, it may be purchased locally.

4. If necessary, prepare and issue N.I.T. (Notice Inviting Tenders) to the concerning suppliers, mentioning different terms, conditions, date and time of opening tenders.

5. Open the tenders at prescribed time on the prescribed date.

6. Prepare a comparative statement of the rates, terms and conditions mentioned in the tender and then study them.

7. If required samples may be received from the firms, who have quoted the lowest rates.

8. Place the purchase order, to the firm selected after the study of samples, rates, terms and other conditions, mentioning the date by which the material must be received.

9. Copy of the purchase order must be sent to the stores, to the department who has sent the requisition, to accounts section and to inspection department.

10. A detailed inspection is carried out after the material is received. If the material is found to be satisfactory, the bill of the supplier is passed and the payment is made to the firm.

Steps in Purchasing:

Following steps are commonly used in purchasing:

1. Purchase requisition (Indenting).

2. Tender Enquiry, evaluation of Tenders, selects the supplier.

3. Placing of orders on suppliers.

4. Follow-up of purchase orders.

5. Receipt of materials.

6. Inspection of materials.

7. Close the order.

1. Purchase Requisition (Indenting):

Actual work of purchase starts from the time purchase department receives purchase requisition (generally known as Indent) from the Indentor. Indentor may be either user department (for non-stock items).

User department/Identor sends his requisition in the prescribed form (varies from organisation to organisation), known as ‘Purchase Requisition Form’ or ‘Indent.’ The indent should be signed or countersigned by an authorised officer only and routes through stores to check materials availability.

The indent sent to the purchase department must be complete.

These generally contains following:

(i) Complete specifications of the material required.

(ii) Quantity of material to be purchased.

(iii) Date by which the material is required.

(iv) Place at which the material should be delivered.

(v) Budget provisions.

(vi) Sample, if required.

(vii) Inspection criteria.

(viii) Warranty requirement.

(ix) Special instructions about source of supply.

(x) Any other instructions.

Purchase department should be given sufficient time to procure material.

2. Tenders:

A tender or a quotation is a written offer to do a work or to provide a material at a given price within a prescribed period and under certain specific conditions.

Tender system is adopted for purchasing the materials at the most competitive rates, and to eliminate chances of undue favour or harassment to any particular supplier. The aim of this is to give equal opportunities to all vendors. The system is common in government departments, and public sector undertakings. Large private sector organisations generally adopt this system for high value items.

Types of Tenders:

Following are the three types of tenders:

1. Single Tender,

2. Limited Tender, and

3. Open Tender.

1. Single Tender:

When the quality is of extreme importance only a reliable firm will be asked to supply the material at rates as decided by mutual negotiations.

2. Limited Tender:

When material is required, firms which are registered by the organisation will invited to tender their rates and the most economic offer will be considered for placing the order.

In this system, the tenders are invited only from some limited firms. Hence this system is called “Limited Tender System”.

The last date of tender, the terms and conditions of supply and payments are mentioned in the tender notice. If the lowest rate quoted by more than one firm is same, the order is placed on a known reliable firm.

3. Open Tender:

This type of tender system is adopted when quantities to be purchased involve large amount. Here this system is also known as “unlimited tender system”. A tender notice in trade journals is published, so that wide publicity can be given.

All the interested firms will apply for the tender form available at certain price. These tender forms contain dates of receiving and opening the tenders, the approximate quantity required, period and place of delivery, specifications and other terms and conditions etc. for supply. A certain amount will have to be deposited by the supplier, as earnest money, at the time of tendering to ensure that the supplier does not back out after his rates are approved.

Global tenders are issued for very costly and high-tech requirements.

Notice Inviting Tenders (Tender Enquiry):

After receipt of purchase requisition, purchase action is initiated by selecting a method of purchase (single source, limited or open tender), a tender enquiry is sent to the selected suppliers or published in the news-papers. Most organisations have their prescribed format for tender enquiries.

The tender enquiry should include the following:

1. Instructions to tenderers:

In order to generate healthy competition amongst the tender rules of contract must be set, which must be clear and must contain:

(i) Place and time of submission of tenders.

(ii) Place and time of opening of tenders.

(iii) Validity period of tender.

(vi) If partial tender can be accepted.

(v) If sample should accompany the tender.

(vi) Time and place of delivery of goods required.

(vii) A reservation enabling the buyer to reject any or all tenders or to place purchase order for parallel goods without assigning any reason.

(viii) If the tenders are required to be submitted in two separate covers (one for technical specifications and commercial terms, while other for prices) or in only one cover containing entire detail.

2. General purchase conditions and special purchase conditions.

3. Detailed specifications and other technical information’s about materials to be procured.

4. Quantity of materials to be purchased.

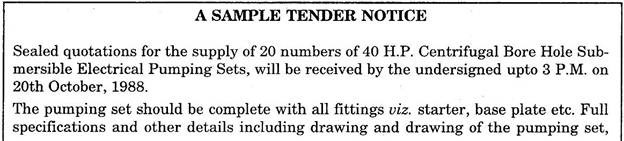

A specimen of Tender Notice is being given below:

After receiving this Tender Notice, supplier must send the tender or quotation so that it may reach before the date and time of receipt. While filling up the tenders, conditions mentioned in the notice must be fulfilled. Other conditions, if any must also be mentioned so that no dispute may arise afterward.

Following should also be clearly mentioned in the tender:

1. Whether the rates are F.O.R. or ex-godown.

2. If rates for items having different specification are quoted, it must be clearly mentioned.

3. Guarantee period, if any.

4. If necessary, drawings must be enclosed.

5. Whether rates are inclusive of sales tax or not.

6. Percentage of advance payment, if desired.

7. Whether packing and forwarding charges are extra or included in the rates.

Receipt of Tenders:

Tenders may be received through post or delivered by hand, in both cases; they must be put in ‘Tender Box’. Tender received by telegram, telex, fax or ordinary letter or in cover not bearing any marking of tender number and due date, opened, must immediately be sealed in a new cover with proper marking of tender number and due date. This cover is then put in the tender box.

If due to unavoidable reasons, opening offenders is to be postponed, it must be communicated to all the firms to whom the tender enquiry had been sent.

The tenders which are posted and received after due date and time of closing of receipt of tenders, are known as late tenders, and are not considered. Tenders posted before the tender opening date but received after due date and time offenders opening are called delayed tenders. These should also not be considered, except in exceptional circumstances like inadequate response or offers received are not competitive.

Opening of Tenders:

The tenders are sent by the suppliers in sealed envelope (the word “tender” or “quotation” and its date of opening must be written on the top of the envelope). On the date of opening, at the prescribed time, purchase officer opens all the tenders or quotations received till that time, in the presence of the representatives of the suppliers, if present.

At the time of opening the tenders or quotations, the purchase officer writes on each tender—S.N. of tender/Total No. of tenders received/No. of pages in that particular tenders e.g., when he writes on any tender 1/13/3, it means, this tender is IV out of 13 tenders received and it has 3 pages. He also attests the corrections and over writings if any, at the time of opening the tender.

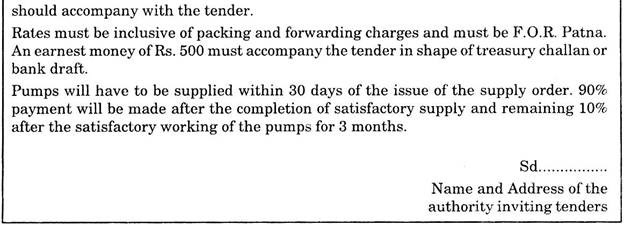

Comparative Statement:

After opening and numbering of all the tenders or quotations, a comparative statement is prepared. This helps to study the proposals in one sight.

Following proforma is generally used for preparing the comparative statement:

This statement gives all the details including alternative offers, terms and conditions of delivery, if differs than that required. This statement should be perfectly correct. Purchase Officer studies this statement thoroughly and takes the advice of the experts, if required.

It is not always necessary to purchase the items only from the firms quoting lowest rates. For this purpose, sample, specifications, make, guarantee period, period of supply, other expenses like freight, sales tax, packing and forwarding charges etc. are considered.

Example 1:

When tenders were invited by a firm it received two quotations as follows:

Supplier A quoted rates as Rs. 5.60 per unit. While supplier B quoted rates as Rs. 5.40 per unit plus Rs. 2000 as fixed charges irrespective of quantity of units to be ordered.

Suggest to whom order should be placed for the purchase of 12,000 units.

Solution:

Rates of suppliers other than fixed charges are:

for supplier A—Rs. 5.60 per unit,

and by supplier B—Rs. 5.40 per unit.

This shows saving of Rs. 0.20 with supplier B. But Rs. 2000 extra has been demanded by supplier B.

Therefore, these extra charges can be compensated if the order is for more than 2000/0.20 = 10,000 roman units.

Therefore, it is economical to place the order for 12,000 units to supplier B.

Check:

Cost for 12,000 units from these suppliers shall be:

Supplier A — 5.60 × 12,000 = Rs. 67,200

Supplier B — 5.40 × 12,000 + 2000 = 64,800 + 2,000 = Rs. 66,800

This shows the supply from B is cheaper by Rs. 400.

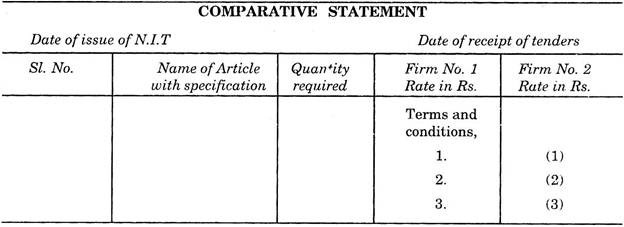

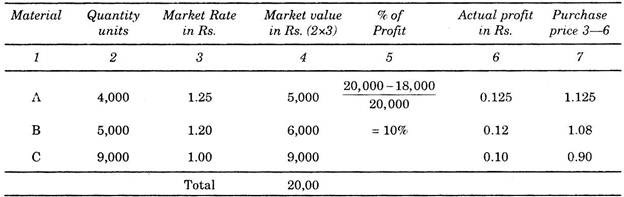

Example 2:

A consignment of following 3 types of materials has been purchased for Rs. 18,000. The market rate of each type of material is shown against each.

Find the purchase price of each unit for each type of material, if all type of materials give same rate of profit.

Solution:

Evaluation of Tenders:

The purpose of evaluation of tender is to determine the ‘lowest evaluated tender’ or ‘lowest technically acceptable tender’. These expressions indicate that order may be awarded to the tender who is not only low in price but also provides advantages in respect of other evaluated criteria, and fulfills the purchasing parameters like: right quality, right time, right price, right source, right quantity etc.

Evaluation is most important while purchasing capital equipment, in such cases additional criteria may be: efficiency, capacity, after sales service, spare parts availability, ease in maintenance, standardisation, energy saving, economy and ease in operation etc.

Negotiations:

Most organisations prefer negotiations as a policy, where full advantage of competition could not be explored. Negotiations are not only carried out for getting prices reduced, but also for getting favourable conditions, like packing, forwarding, insurance, transportation, delivery schedule, penalty, discount, payment terms etc. For effective negotiations, purchase manager must know negotiating techniques and skills for better bargaining.

Major objectives of negotiation are:

(a) To obtain a fair and reasonable price for specified quality,

(b) To get the supplier to perform the contract on time,

(c) After sales service, availability of spares, guarantee, warranty, buy back clauses and supply of free spares with capital equipment,

(d) To exert some control over the manner in which the contract is performed,

(e) To persuade the supplier to give maximum cooperation,

(f) To develop a sound and competitive relations with the competent suppliers.

Price Analysis:

Price analysis is defined as the examination of a seller’s price proposal (bid) by comparison with reasonable price bench-marks, without examination and evaluation of the separate elements of costs and profit making up the price.

There are 4 ways of conducting price analysis:

1. Analysis of Competitive price proposals.

In this approach following conditions must be satisfied for fair and reasonable prices:

i. Response by atleast two qualified sources.

ii. Supplier competed independently for the award.

iii. Lowest bidder does not have an unfair advantage over its competitors.

iv. Lowest evaluated price is reasonable.

2. Comparison with regulated, catalogue or market price.

3. Comparison with historical quotes (earlier-quoted prices) or prices for the same or similar items.

4. Use of independent cost estimates.

Methods for Smaller Value Purchases:

Whenever the purchases are made for smaller value, there is no need for following lengthy procedure of tendering.

In such cases following methods are generally adopted depending upon the organisational policies:

(i) Purchases through personal enquiry:

In these cases quotations (not less than 3) are collected personally and order is placed on the spot and purchase is done either in cash or by a letter order and cheque payment.

(ii) Repeat orders:

The order may be placed against previous orders, without calling for fresh tenders, provided the supplier is ready to supply the items at the same rate and conditions.

3. Placement of Purchase Order:

The contract is concluded with the posting of the purchase order to the successful bidder. The purchase order must be posted within the validity period of the offer. It becomes legally binding only on its acceptance by the other party.

Acknowledgement of purchase order should be closely watched and disputes, if any, on any of the terms or other stipulations must be settled immediately so as to bring a legally enforceable contract into existence.

Purchase order must contain:

(i) Complete description of material/equipment.

(ii) Item wise quantity, unit rate and value.

(iii) Date of delivery.

(iv) Terms of delivery.

(v) Prices (firm or variable), provision of taxes and duties.

(vi) Clause for liquidated damages.

(vii) Payment terms and paying authority.

(viii) Security deposit and performance guarantee.

(ix) Warranty.

(x) Consignee addresses and despatch instructions including transit insurance and freight payment.

(xi) Instructions governing supply, inspection and testing criteria and drawing of samples.

(xii) Place of inspection.

(xiii) General purchase conditions.

(xiv) Arbitration and jurisdiction clause.

(xv) Force Majeure clause.

(xvi) Provisions for cancellation, removal of rejects, penalty, bonus etc.

Purchase order is a letter sent to the supplier asking him to supply the said material. At least six copies of purchase order are prepared by the purchase section and each copy is separately signed by the Purchase Officer. Out of these copies, one copy each is sent to the storekeeper, supplier, Accounts section, to the Inspection department and to the department placing the requisition and one copy is retained by the Purchase department for record.

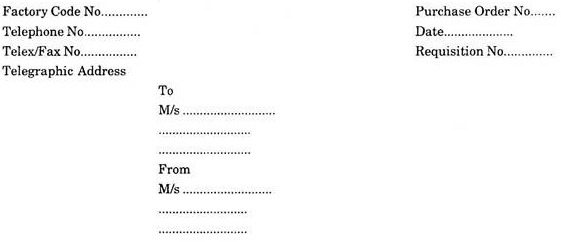

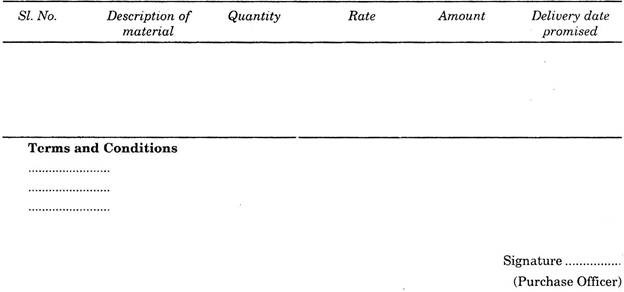

Ref. your Tender/Quotation No………………. Date…………… Please supply the following in accordance with the terms and conditions mentioned as under:

Specifications for Ordering Machinery:

Purchase of machinery for a manufacturing concern calls for great skill and knowledge of the particular type of machine. This problem has to be looked at from three points of view.

These points are:

(a) Quantity,

(b) Quality, and

(c) Price.

It is from the point of view of quality that specifications have to be laid down before ordering machinery. There are many forms of specifications.

Thus important among them are as under:

(i) Brand or Trade Name:

The buyer depends entirely on the producer’s reputation for quality, when he specifies material by brand or trade name.

(ii) Blue Print or Dimension Sheet:

This is prepared by production engineering department to meet the special requirements of the concern. This form of specification is useful in the purchase of tools and fixtures.

(iii) Chemical Analysis or Physical Characteristics:

Specifications by chemical analysis or physical characteristics are considered to be ideal for raw-materials in the metallic class.

It is essential to conduct laboratory tests to check such specifications.

(iv) Description of Purchase or Use:

It is very advantageous to the buyer. Here it would be the responsibility of the supplier or seller to meet the requirements of specification.

For example, when tools or machines are to be bought, the buyer generally does not possess complete technical knowledge about them. It would be desirable to specify the performance along with physical and mechanical requirements.

(v) Samples:

The use of sample as form of specification has its limitations. Sometime disputes may arise and, therefore, samples should be used in the form of specifications. Samples should only be used when more effective firms are not available.

(vi) Identifications with Standard Specifications:

This is the most satisfactory method; of course, the standard must be such that the buyer’s requirements must be met. Sometimes standards for certain materials may be fixed by reputed institution and have been accepted by all. This facilitates trade and commerce considerably.

The specifications given must have the following essential features:

1. It should be as simple as possible.

2. It should be exact.

3. It should be capable of verification.

4. It should be such that a number of suppliers can meet it.

Standard Specifications:

These are published in our country by Indian Standards Institution. Standard specifications published by Indian Standards Institution (now Bureau of Indian Standards) are called “Indian Standards”.

These are written in a very clear and concise manner. Wherever necessary, they are supplemented by tables, schedules and diagrams. Their study will give some idea as to how specifications are to be written.

Indian standards are constantly being revised and amended so as to keep them up-to-date and so it is desirable to refer always to the latest version. From First April 1987, the “Indian Standard Institution” has been renamed as “Bureau of Indian Standards”.

Earnest Money:

It is the amount of money, which is demanded along with the tenders, so that the supplier may not back out at the time of accepting the rates. If the supplier does not agree to supply the material at the quoted rates, his earnest money can be forfeited.

Security Deposit:

For the tenders of large supplies, the firm whose rates are lowest is asked to deposit security deposit after accepting his lowest rates. When the firm makes deposit of security money, he is given supply order. If the firm fails to supply the materials of right quality, quantity and at agreed rates, his security money is forfeited.

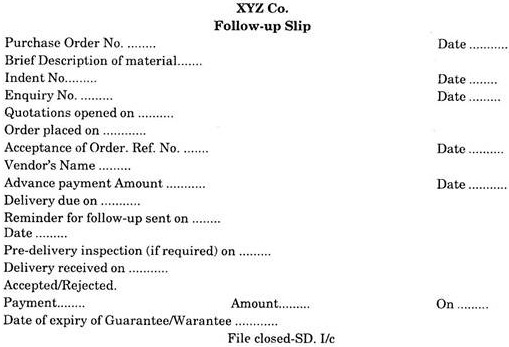

4. Follow-Up:

Function of purchase department does not cease with the placement of purchase order. There should be a regular follow-up of purchase orders placed. A register for this purpose is maintained for all the orders placed. Supplying firms should be contacted constantly so as to ensure timely supply of materials.

If the delivery date is expired, firm should be asked to indicate the expected date for supply of materials and extension might be granted subject to such penalties as may be specified in the contract or otherwise, if necessary. Critical items need vigorous follow-up, while others need routine follow-up.

The follow-up section should carry out following functions:

(i) To secure an acceptance of order from the seller.

(ii) To secure a commitment for delivery schedules.

(iii) To chase various activities from placement of orders till final payment after receipt of satisfactory and timely supply of material.

Critical items require vigorous follow-up, while others a normal one. Generally printed letters are sent to the sellers for expediting the supply of materials. Normally a follow-up card for each purchase order is maintained in the section.

A sample follow-up card is given here under:

5. Receipt and Inspection of Material:

All incoming material on receipt is physically checked, counted and then referred to inspection/quality control department, to ensure whether it meets the purchase order requirements.

The rejected items are returned to supplier, while accepted items are identified, and sent to storage for recording, and keeping them properly at their locations. Some-times inspections of items are carried out at suppliers place, known as pre-delivery inspection. On receipt of such items it must be got ensured from the same team, which carried out pre-delivery inspection, that the material is same.

Purchase department then verifies the bills and ensure timely payment. The rates, quantity accepted are verified, and copy of purchase order, sellers invoice, inspection note and material receipt note are forwarded to the accounts department for payment.

Record Keeping:

Following basic records are essential for effective operation of purchasing department:

1. Record of open orders concerning the status of outstanding orders.

2. Record of closed orders provides a historical record of all completed purchases.

3. Purchase log provides an ongoing record, in numerical sequence of all purchase orders issued.

4. Commodity record provide vast reservoir of materials data for each major material and service that is purchased repetitively.

5. Supplier record provides quick access to information about suppliers.

6. Contract record provides immediate access to all contract documents.

Essay # 8. Principles of Purchasing:

(i) Right Time:

Since delayed supply can cause shortages resulting in disruption of production schedule and might mean avoidable losses. In order to ensure timely supply, proper follow-up and control over delay in transportation, placing order and inspection of incoming material is essential.

Lead time also plays an important role in identifying the right time. Lead time is the time that elapses between ordering goods, receiving them and placing them into use. For longer lead time, working capital commitment will be more. The stock has to take care of normal consumption during average lead time, as well as normal consumption during abnormal lead time. Stock is also required to take care of increase in consumption during normal lead time.

From above, it is clear that as the lead time increases, the inventories will have to increase, resulting in increased working capital.

In order to control major components of lead time, purchaser is expected to:

(a) Follow-up and expedite the supply,

(b) Take efforts to reduce transportation/shipment period taken by road/rail/marine carriers,

(c) Control internal lead time, which includes the time needed for the conversion of the indent to a purchase order. The internal lead time depends upon the systems, procedure, initiative etc.,

(d) Avoid delays by expediting the inspection of material received for getting it approved for use.

Main reasons for increase in lead time are:

(a) Bad planning,

(b) Wrong specifications,

(c) Incomplete indent,

(d) Wrong estimation of requirements,

(e) Lack of efforts in controlling lead-time,

(f) Lengthy procedures,

(g) Delays in decision-making,

(h) Incomplete purchase order.

(ii) Right Price:

As per economics, ‘price is the value expressed in terms of money’. Here the emphasis is on the word ‘value’ which may mean utility value, aesthetic value, and moral value to different people.

But here we are more concerned with the exchange value. Money is that commodity which is used to measure this exchange value, and its quantitative expression denotes the ‘price’. Therefore ‘right price’ is the ‘ideal exchange value’ which is fair and reasonable.

The right price is not necessarily a lowest price; it is the best ultimate value, which is generally determined with other factors, such as quality, quantity, delivery, availability, standard/non-standard, repetitive or non-repetitive, seasonal or non-seasonal. Other factors influencing the price are: reliability, financial and technical capability of supplier, after-sales service, market structure etc.

Since main aim of purchasing is to pay reasonably low price for the best values obtainable, determination of right price is very important. The basis for deciding the right price depends upon the type of material, market conditions, availability, demand and supply, and socio-politco-economic aspects.

Right price includes ordering cost and carrying cost. ‘Make or buy’ decision help to decide when to go for manufacture or purchase. ‘Value analysis’ also helps in reducing the price. For getting right price, competitive bidding and negotiations should be adopted.

(iii) Right Source:

Various factors considered for selecting a ‘right source’ are reliability, quality, cost, past performance, after-sales service, public relations etc. Market research is carried out for locating reliable source (vendor).

Source identification process involves the following:

(a) Vendor selection

(b) Vendor development

(c) Vendor rating.

Following are the main sources for the procurement of items:

(i) Authorised dealers or manufacturers.

(ii) Local dealers.

(iii) Buy getting them manufactured.

(iv) Right Quantity:

In order to decide the quantity of item to be purchased, the purchase department should remain in touch with production department. Purchase department should carry out ‘inventory analysis’ and ‘operation research’ to decide the quantity to be purchased, especially when dealing with discount offer to decide the optimum quantity.

The problem of determining the right quantity is interlinked with the right time.

(v) Right Quality:

Since quality aspect is most important factor, purchase manager, for the purpose of ensuring good quality should take cognisance of quality assurance system adopted by the supplier firm, brand/make of the item, standardisation, past performance/reputation of supplier firm/brand of the item etc.

While inviting the tenders or placing the enquiries, quality specifications mentioning tolerances etc. should be clearly spelled out. Right quality means suitability of an item for its intended purpose.

(vi) Right Transport:

Purchase department’s function is also to ensure that the material is shipped from the vendor’s premises to the company. Transportation cost is a substantial part of the cost of materials purchased. It is higher if suppliers are located far away and in cases of ore, coal, mineral etc.

The buyer’s efforts are to seek constant improvements in transportation with a view to cutting down transportation costs, achieving greater speed, and better quality of service. It is possible to reduce the transportation cost by appropriate choice of mode of transport, selection of route and adopting techniques for optimum transportation costs.

The choice of the mode of transport depends upon type of material, weight, size, volume, safety, handling charges, time available, loading and unloading charges etc.

The usual modes of transport are:

(i) Railways,

(ii) Road transport,

(iii) Water transport,

(iv) Air-transport, and

(v) Transportation through pipe lines.

(vii) Right Procedure:

Right procedure to be adopted has to be formally developed for the pre-purchase, ordering, and post-purchase systems. Pre-purchase system means initiating the purchase through indents requirement, planning, selection of suppliers, obtaining quotations and evaluating them.

With purchase order generally an acknowledgement copy is also sent to the supplier, who then return it as a written acceptance of supply order and to abide by the terms and conditions mentioned in the order. Post-purchase systems include follow up with the suppliers.

(viii) Right Contract:

Purchase order is a legal document that binds selling company with the buying company regarding various terms and conditions such as insurances, sales tax, octrai, customs, excise, breach of contract, settlement of dispute, F.O.B., F.I.R., C.I.F., etc. should be clearly mentioned.

Essay # 9. Methods of Purchasing:

(a) Purchasing strictly by requirement.

(b) Purchasing for a specified period,

(c) Market purchasing.

(d) Contract purchasing.

(e) Central purchasing.

(f) Through Directorate General of Supplies and Disposals.

All these methods of purchasing are described in brief below:

(a) Purchasing Strictly by Requirement:

This is also known as hand to mouth purchasing. When a job is taken in hand only then the required quantity of material for that particular job is purchased.

Therefore, it is suitable for the concerns, having less working capital.

Advantages:

(i) The market fluctuations will not affect as costing is based on the market rates.

(ii) Small storage space will be required.

Disadvantages:

(i) Distribution costs will be higher.

(ii) Sudden demands cannot be met.

(iii) Bargaining is not possible due to the small amounts involved.

(b) Purchasing for a Specified Period:

Generally, the standard items are regularly purchased in quantities that will be sufficient for a particular future period.

Advantages:

(i) As the order is received, production can at once be started.

(ii) Short duration market fluctuations will not affect much, being small quantities.

(iii) The involved working capital will be less.

(iv) Less storage space is needed.

(v) Cost analysis is easier.

(c) Market Purchasing:

The reasonable requirements based on production planning are calculated. Market trends are analysed and then purchasing is done.

Generally, raw materials in process of manufacturing are purchased by this method.

Advantages:

As purchasing is done in lot, distribution cost is less.

Disadvantages:

(i) If the market topples, there is big loss.

(ii) Large storage space is required.

(d) Contract Purchasing:

Contracts are given to suppliers for large amounts of future requirements, for a certain period (say 2-3 years), subject to review and cancellation with a specified period of notice.

In addition, contract purchasing can be classified in the following two groups:

(i) Rate contract and

(ii) Running contract.

(i) Rate Contract:

Under this system rates are fixed for certain items of stock or component part of product for certain period. In this system, no tenders are invited but rates are fixed by analysing the market trends by the purchaser. Any firm whatsoever is interested in supplying the material at these fixed rates for that duration can make the supply.

Products like fans, paints, cables, tyres etc. can be purchased through this method. This is simple and convenient method. In this method, it is not necessary to purchase from one supplier and they can buy the materials from any-body.

(ii) Running Contract:

In this, the rate as well as quantity for certain period is decided by buyer and supplier. As soon as the desired quantity is supplied by the suppliers, the contract is automatically terminated.

Advantages:

(i) It avoids necessity for keeping stocks.

(ii) It gives a measure of safety to suppliers.

(iii) The purchase is not affected by market fluctuations and the supply is ensured.

(iv) As fewer purchase orders are required to be placed, it therefore, reduces to a great extent clerical work, accounting and receiving work etc.

(v) The purchase department is relieved from the routine work and it can pay more attention on the major works.

(vi) No time is needed to be wasted in calling quotations and finalising the purchase. It ensures quick purchases.

(vii) The maintenance of records is improved as the items are standardised.

(viii) Normally during the period of contract, there is no change in price rate.

(e) Central Purchasing:

Large concerns or certain big government concerns may have section wise stores at different places and each section may have a separate store. In such a case, there arises a problem as to whether each store should make its own purchases or whether purchases should be made by the central stores that would go on supplying materials to section wise stores.

If the local sectional store is allowed to make its own purchases there would be no delay and the shops can get materials very soon after they have sent their requisitions, but local purchases may sometimes lead to malpractice. The purchase officer may have some kind of under- Standing with the local dealers and this may result in purchases at higher rates.

Advantages of Central Store Purchases:

(i) When the central stores make a purchase, it is on a large scale, naturally it can obtain a good bargain and things will be cheaper.

(ii) A strict control and check is possible. Therefore, there will be a little chance of malpractices.

(iii) It can have direct contract with the manufacturers and can get things as per specifications.

(iv) Scientific arrangements for storage can be made.

The only difficulty in this system is that sometimes there may be delay in getting material from the central stores but this can be minimised by supplying sufficient quantities to the sectional stores.

(f) Directorate General of Supplies and Disposal:

To avoid unpleasant situations in various government departments in purchasing materials and equipment’s there is Central Purchasing Organisation which provides supplies at very cheap rates. This relieves a lot of botheration to the individual department.

This department enters into contract with various firms for supply of certain materials to government departments during the year at agreed rates. These firms have to certify that they are not supplying to others the same materials at rates lesser than that mentioned in the rate contract.

The various government departments as and when required place order on the firms for the supply of materials at the rate contract prices.

Directorate General of Supplies and Disposal with various branches in the country for the Central Government Department and the Central Purchases Department for State Government Departments are such organisations.