Here is an essay on the ‘Purchasing of Materials’ for class 11 and 12. Find paragraphs, long and short essays on the ‘Purchasing of Materials’ especially written for school and management students.

Essay on Purchasing

Essay Contents:

- Essay on the Meaning of Purchasing

- Essay on the Objectives of Purchasing

- Essay on the Organisation of Purchase Department

- Essay on the Centralised or Localized Purchasing

- Essay on the Functions of Purchasing Department

- Essay on the Methods of Purchasing

- Essay on the Steps in Purchasing Procedure

- Essay on the Evaluation of Purchasing Performance

Essay # 1. Meaning of Purchasing:

Purchasing is the first phase of Materials Management. Purchasing means procurement of goods and service from some external agencies.

The object of purchase department is to arrange the supply of materials, spare parts and services or semi-finished goods, required by the organisation to produce the desired product, from some agency or source outside the organisation.

The purchased items should be of specified quality in desired quantity available at the prescribed time at a competitive price. In the words of Alford and Beatty, “Purchasing is the procuring of materials, supplies, machines, tools and services required for equipment, maintenance, and operation of a manufacturing plant“.

According to Walters, purchasing function means “the procurement by purchase of the proper materials, machinery, equipment and supplies for stores used in the manufacture of a product adopted to marketing in the proper quality and quantity at the proper – time and at the lowest price, consistent with quality desired.”

Thus purchasing is an operation of market exploration to procure goods and services of desired quality, quantity at lowest price and at the desired time. Suppliers who can provide standard items at the competitive price are selected.

Purchasing in an enterprise has now become a specialised function. It was experienced that by giving the purchase responsibility to a specialist, the firm can obtain greater economies in purchasing. Moreover purchasing involves more than 50% of capital expenditure budgeted by the firm.

According to Westing, Fine and Zenz “Purchasing is a managerial activity that goes beyond the simple act of buying. It includes research and development for the proper selection of materials and sources, follow up to ensure timely delivery; inspection to ensure both quantity and quality; to control traffic, receiving, storekeeping and accounting operations related to purchases. ”

The modern thinking is that Purchasing is a strategic managerial function and any negligence will ultimately result into decrease in profits.

Essay # 2. Objectives of Purchasing:

The objectives of Purchasing should conform with the overall objectives of the organisation. It is one activity where reasonable economies can be accomplished.

The following are the main objectives of purchasing:

(i) Purchase of Satisfactory Material:

To procure materials, which are most appropriate to the product and are supplied in right quantity and quality at right time and right price.

(ii) To Control the Quantity of Material:

Purchase of material needs investment. Buying too much or too little quantity may not be in economic interest of the organisation i.e. too much quantity may unnecessary block the capital whereas too little purchase order may affect the regular supply of production. By analysing the requirements of different items and regulating the appropriate ordering policy the purchasing department ensures economic capital investment and regular flow of production:

(iii) Proper Negotiations with Suppliers:

Search for potential suppliers is an important activity of purchasing. This ensures timely supply of materials in the most economic manner. Wrong selection of supplier may be harmful to the enterprise both in terms of price and delivery time. Purchasing department through its dealing with suppliers creates goodwill and enhances the reputation of the enterprise.

(iv) Controls Proper use of Materials:

By analysing the requirements of various departments of the organisation, the purchase department avoids duplication, waste and obsolescence of materials and equipment’s.

(v) Co-Ordination with other Departments:

The purchase department should develop full co-ordination and maintain close relationship between various departments of the organisation.

(vi) Maintenance of Company’s Goodwill:

By maintaining the quality standards of the material the purchasing activity is instrumental in generating the confidence of consumer in the product of the company.

(vii) Other objectives can be:

(a) Exploration to locate new suppliers.

(b) Information about new materials and processes, which can reduce the cost of production and improve the performance of the product.

(c) To achieve economy and efficiency in the activities of the purchase department by analysing.

Essay # 3. Organisation of Purchase Department:

The composition purchase department varies according to the size of the enterprise its comparative significance towards procurement and the capability of the purchase personnel.

In organisations engaged in procurement of smaller range of items but from limited number of suppliers the purchase officer is attached to controller of accounts. In organisations with job or batch system of production, purchasing becomes a complicated exercise and needs regular thorough co-ordination with production department. In such cases purchase manager is directly attached to production manager.

The size of the purchasing departments depends on the nature of products manufactured by the organisation, sizes of the production runs type of the manufacturing system.

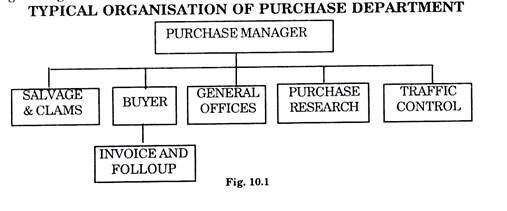

In general, the purchasing department can have the composition given fig. 10.1.

Typical Organisation of Purchase Department:

In the organisation, purchase manager occupies an important position. He should be a man of quick decision-making power, pleasing personality, quality of good leadership and farsighted approach should be inherent in him.

Essay # 4. Centralised or Localized Purchasing:

Centralised or Localized purchasing policy depends upon the nature of the manufacturing organisation.

In companies with only one plant there is mostly Centralised purchasing system. In multi-plant organisation sometimes centralised purchase system can be adopted on the basis of homogeneity in terms of product produced, location of plants and suppliers of the material required etc.

Generally in the case of multi-plant organisations decentralised location for purchasing units are preferred in each plant. This system is more appropriate in cases where plants are distantly situated and are producing different kinds of products.

Advantages of Centralised Purchasing:

The following are the main advantages of having a centralised purchasing section:

(i) This ensures undivided responsibility. The officials can concentrate in their operations more efficiently.

(ii) There can be economies due to buying in bulk. Bulk buying increases the bargaining power of the department and can encourage quality discounts

(iii) Reduces inventory carrying costs as well as investment in inventories.

(iv) More specialised personnel in purchasing can be employed.

(v) There is more economy in maintenance of records, easy adaptability to the market conditions. All this leads to most efficient and effective use of the resources.

Disadvantages of Centralised Purchasing:

(i) Localized purchasing can have more flexibility in purchases.

(ii) Cannot have close liaison with suppliers as well as other departments of the organisation.

(iii) Cannot properly deal the demand and supply problems to avoid misunderstanding and possibility of wrong purchases.

Essay # 5. Functions of Purchasing Department:

The main object of purchase department is to purchase items of specified quality and lowest price.

To accomplish this, the functions of the department are:

1. Processing the Requisition:

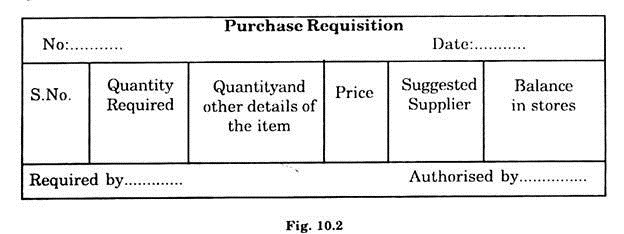

The departments of the organisation communicate to the purchase department their requirement for various items through requisition form. The format of requisition form contains the details of the quality, and other necessary specifications about the item to be purchased. The requisition is to be signed by the competent authority.

The purchase requisition is prepared in duplicate and the original copy is sent to the purchase department. The purchase department processes and scrutinizes the requisition and then proceeds to other operations for making purchases.

2. Location and Choice of Suppliers:

The potential vendors are contacted through authorised representatives; their catalogues and sample of the items are inspected and examined either at the purchaser’s place or at the vendor’s place. On the basis of findings from inspection, examination of samples and analysis of the quoted prices, suppliers are approved for placing the orders.

The criterion for the ultimate choice of a vendor is based on following aspects:

(i) Reliability of Supply:

Past performance specially in the time of crisis as well as sound financial position of a supplier classifies him to be reliable.

(ii) Assurance of Timely Delivery:

The punctuality pattern in observing the delivery schedule provided by the purchaser during past deals ensures the prompt supply by the vendor.

(iii) Other Considerations:

After sales service, technical assistance, attitude with regard to the goods rejected by the purchaser and co-operation in disposal of waste are some important guiding factors for the choice suppliers.

Purchasing agents continually scan the market place in search of potential new suppliers. Continued monitoring and evaluation of the supplier performance is necessary and should be based upon actual results.

3. Placing of Orders:

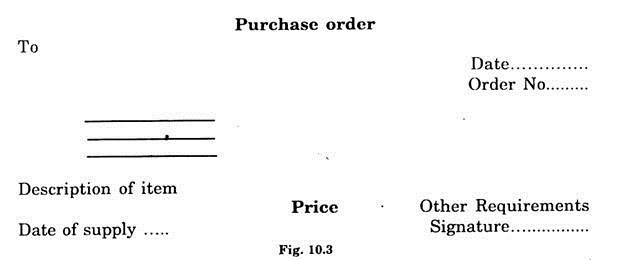

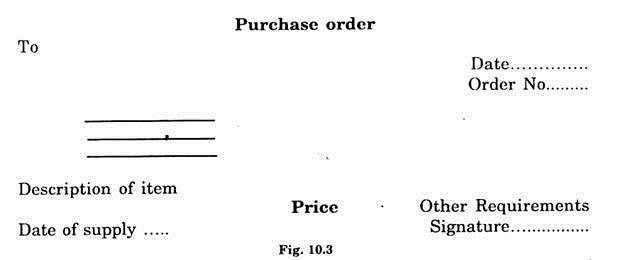

The purchase department tries to purchase the materials with desired quality and quantity at the most advantageous terms. All purchases should be made through a purchase order in a specified form and duly signed by some authorised person. The purchase order must contain the details about the supplier, description of the items required, corresponding prices and amount required.

The format of standard purchase order can be:

As a rule original copy is sent to the supplier, one copy is retained by the purchase department and one copy is sent to the concerned department requiring the ordered items.

4. Follow-Up or Progressing the Purchase Orders:

Receiving the ordered material at the right time is most important for an organisation. Late deliveries can close the enterprise. For this follow- up or expediting the purchase order after waiting for some reasonable time is essential. The priority of follow-up operations should be given according to the importance or classification of items e.g. ‘A’ class items are to be given top most priority.

It is also necessary to review the outstanding orders at regular intervals.

5. Invoices received from suppliers are checked and verified with the order specification.

The process includes the following activities:

(i) The goods supplied are of desired specifications both in quality and quantity.

(ii) Comparison of quoted price and the price charged in the invoice.

(iii) If some goods supplied does not conform with the specifications or are damaged during transshipment then steps are taken for adjustments on claims.

6. Some other functions of purchase department can be:

(i) Delay in availability of requisitioned material should be conveyed to concerned departments in time.

(ii) To maintain records regarding suppliers, their performance in past, products available with them, probable delivery period for each order etc.

(iii) To dispose off out-dated and scrapped items.

(iv) Control stores operation of receiving the items from vendors and issuing it to concerned departments of the organisation.

(v) To evaluate the performance of the department.

(vi) To collect information about trends in market regarding availability of improved goods and services and also about the substitute products in case of emergency.

(viii)To handle damages and demurrage claims.

Essay # 6. Methods of Purchasing:

There are a number of methods used by different purchase departments. The methods used depend on the classification of products in the production system, policy of the organisation and behaviour of the market.

Following are some popular methods of purchasing:

(i) Purchasing According to Requirement:

In such cases an order is placed only when there is some need for the product. This method is appropriate for those items, which are not of regular and common use in the production process.

These items are generally not stored in inventories. In such cases the purchasing department should keep a record of reliable and trustworthy suppliers who were sincere to the organisation in past.

(ii) Purchasing for some Definite Future Period:

This method of purchasing is generally used for those items, which are regularly consumed, but the consumption is comparatively low and the price changes for these items are not much.

(iii) Market Purchasing:

The policy of making the purchases at a time when the fluctuations in price of the items provide advantage to the purchaser is known as market purchasing. This method provides procurement at lower price and saving in purchase expenses.

This method is useful in situations where major price variations are prominent. Here the purchasing may not relate with the production needs and if the assessment of price fluctuations is wrong then the organisation may suffer losses.

(iv) Speculative Purchasing:

Here excessive purchases are made when market is low for the item with the hope of earning profit by selling the items purchased in excess at a higher price. This procedure is most suitable in the case of staple commodities e.g. cotton for textiles. The merits of this method lies in more profits and more protection against shortages. This method involves more financial commitments on the part of the organisation.

(v) Contract Purchasing:

Here the purchase department enters into agreement with various suppliers to supply the items at some future period periodically. In the words of Alford and Beatty, “All purchasing is contract but the term, ‘contract purchasing’ is applied to that special contract which calls for differed delivery a period of time.” According to Sprigel, “The purchasing under contract is usually formal for the needed material, the delivery of which is frequently spread over a period of time.”

The organisation tries to enter into the contract when prices are comparatively low. Here the supply is ensured per scheduled requirements as well as there is protection against frequent price fluctuations e.g. car manufacturers, coal consumers, flour mills etc.

Here the purchaser is able to reduce the size of the inventory and supplier is assured for stable demand. Thus this method is in the interest of both purchaser and supplier.

(vi) Scheduled Purchasing:

It is a scientific method of purchasing. The purchasing is scheduled according to requirements of various departments of the organisation. Vendors know in advance about the future demand of the purchaser. Proper balance is made between amount procured amount required. Sprigel is of the opinion that scheduled purchasing is closely related to carefully controlled production.

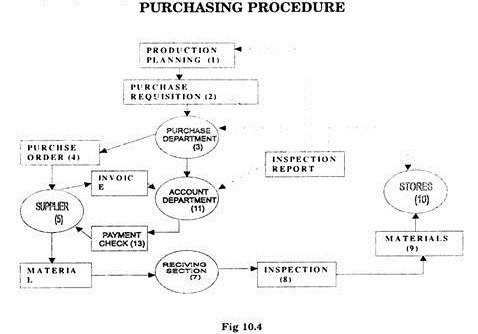

Essay # 7. Steps in Purchasing Procedure:

The following is the routine commonly followed by various purchasing departments:

(i) Various departments are requested to send their requirements on a proper requisition form (see fig. 10.2). This authorises the purchase department to procure the requisitioned items i.e. to issue purchase order.

(ii) Purchasing department consolidates the requirements from various departments to know the total requirement for each item.

(iii) Market exploration is made to locate the goods and services of desired quality and quantity at the reasonable price.

(iv) Potential suppliers are identified from catalogues, quotations and past records.

(v) Purchase order in specified form (see fig.10.3) is prepared and sent to the approved suppliers. Purchase order is the commitment of the buyer to the supplier establishing a contractual relationship between buyer and seller.

(vi) After some time of placing the order, follow-up process starts to get quick delivery of the items. The follow-up procedure implies acceptance of the order and promise to supply the items on desired date.

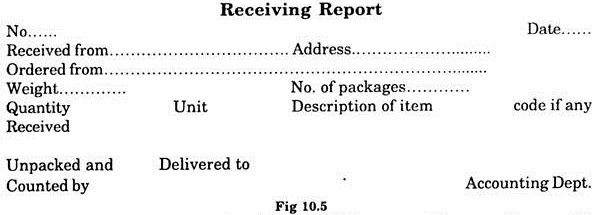

(vii) The items are received by the purchasing department at the time of delivery and the items received are compared with purchase order. The checking of the delivered goods is done with regard to (i) Prices charged and quoted (ii) approval of the invoice (iii) to ascertain the quality and quantity of the items.

The receiving report can be given on a specified form given below:

(viii) Defective items i.e. items which are not in accordance with the -specifications laid down in the purchase order are returned to the supplier on credit note for exchange.

The received consignment is then delivered to the stores department or the department which requisitioned the material.

Essay # 8. Evaluation of Purchasing Performance:

Purchasing performance in most areas is quite difficult to be expressed in quantitative terms. The intangible nature of primary purchasing responsibilities prohibits the direct measurement of purchasing accomplishments.

Most of the organisations follow fairly broad approach on the lines described below:

(i) Evaluation of Purchasing Managerial Personnel:

The experience, qualifications and knowledge of purchasing managers in relation to the materials purchased, suppliers and markets etc. are analysed.

(ii) Analysis of the procedures adopted for purchasing.

(iii) Buying Proficiency:

This is measured by:

(a) Checking the actual price paid with target price

(b) Savings resulted from negotiations

(c) Percentage of overdue orders

(d) Percentage of stock outs caused by late deliveries

(e) Gains and losses from forward buying activities

(f) Number of orders issued/period.

(iv) Purchasing Efficiency:

It involves evaluation of workloads, personnel utilisation, operating costs and processing times as related to specific volumes of purchasing operations. Some organisations continually audit a small random sample of completed orders to determine.

Correct method of purchase, consolidation of orders requirements advantageously, selection of suitable vendor. Such audit frequently detects newly developing problems more quickly. Moreover the psychological effect of the audit generally stimulates to more consistent levels of performance.