The following factors should be considered while planning a factory building:- 1. Nature of Manufacturing Process 2. Flexibility 3. Expandability or Future Expansion 4. Service Facilities 5. Employee Facilities 6. Lighting 7. Heating 8. Ventilating 9. Air-Conditioning 10. Other Consideration.

Consideration # 1. Nature of Manufacturing Process:

1. Buildings required to house continuous or intermittent production processes differ quite a lot in their design. Seldom the same building is suitable for both these types of productions.

2. Building design varies with the type of product to be manufactured and the equipment utilised.

Buildings manufacturing rubber tyres, clothes, machine tools, glass bottles, presses or steel plates possess designs which differ as regards floor loading, height of the ceiling, bay size, ventilation and humidity requirements, etc.

Consideration # 2. Flexibility:

ADVERTISEMENTS:

Suppose a factory owner is interested to leave his original product and decides to manufacture another product which he feels is probably more profitable. He cannot construct another building and thinks of using the same old factory building for making the new product.

This is not strange; many old cotton mills and sugar factories are now being used for light engineering works. At this stage the question arises, whether the old factory building is flexible enough to be used for manufacturing the new product?

Thus, flexibility in the factory building avoids it from becoming obsolete and imparts to it (i.e., to the building) the same operating efficiency even when there is a change in product, process or technology.

The flexibility of a factory building can be increased by:

ADVERTISEMENTS:

(i) Providing a large floor area unobstructed by pillars, columns, etc., so that processes and layouts can be changed easily;

(ii) Keeping adequate roof truss strength and ceiling height so that newer material handling equipment can be installed and inside building temperatures may be controlled;

(iii) Erecting no permanent obstruction such as walls and partitions on the production floor;

(iv) Providing individual motor drives for the machines;

ADVERTISEMENTS:

(v) Providing overhead electrical grid so that electrical supply (at various voltage levels) can be tapped near the equipment;

(vi) Making heavy duty floors to accommodate even heavier machines;

(vii) Making machine installations such that the machines can be moved easily when layout changes are required.

Consideration # 3. Expandability or Future Expansion:

Keeping provision for future expansion has become very necessary because of the enormous expansion of industry in recent years. Due consideration is being given to future expansions while designing a new building; but before that a plant site size large enough for current needs and for future expansion requirements should be purchased. While designing the factory building, it is thought of carefully that in future, whether the building will expand length or breadth-wise or more number of floors will be constructed.

ADVERTISEMENTS:

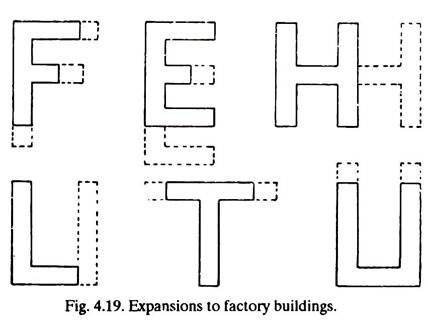

If it is decided to expand length- and breadth-wise, false and non-load bearing end walls are constructed to make expansion easier. If more floors are to be added in the building above the ground floor, adequate foundations, supports, etc., should be provided in the original structure to carry the weight of added floors. Where processes are housed in separate buildings, certain plan shapes have become popular due to their ease of extension (expansion) and they are in the form of the letters F, E, H, L, U, T, etc.; (refer Fig. 4.19) original building is in full lines and extensions are shown dotted.

Consideration # 4. Service Facilities:

Service facilities such as firefighting equipment, sewage-treating systems, emergency and standby power equipment, compressed-air equipment, heating, lighting, ventilating and air-conditioning equipment, etc., should be housed separately and suitably.

Consideration # 5. Employee Facilities:

Good employee facilities are incentives to the employees of an organisation and they build up the morale of the employees. Adequate provision should be kept as regards washroom and toilet facilities, dispensaries, cafeterias, recreation rooms, parking areas etc.

Consideration # 6. Lighting:

ADVERTISEMENTS:

One of the most important environmental factors is Lighting which increases productivity, reduces accidents and adds to employee satisfaction.

Advantages of Good Lighting:

(i) Increased output, therefore decreased costs,

(ii) Reduced accidents,

ADVERTISEMENTS:

(iii) Improved product quality,

(iv) Better visibility, therefore less strain on the eyes,

(v) Less spoilage and consequent rework,

(vi) Better floor space utilisation and improved house-keeping,

ADVERTISEMENTS:

(vii) Plant neatness and cleanliness can be better maintained.

(viii) Easier and better supervision of materials in process and finished products, and

(ix) Improved morale among employees resulting in reduced labour turnover.

Characteristics of Good Lighting:

1. Light should be of sufficient intensity for the particular operation being performed.

2. Light should be equally bright throughout the shop floor.

ADVERTISEMENTS:

3. Light should be diffused and not glaring.

4. There should be adequate but not sharp contrast between each part of an object and from the surrounding background.

5. Light should not permit marked shadows.

6. Dazzling light should be avoided.

Nature of Light:

1. Natural light is actually the best for working, but it varies with the time of day, time of the year and weather (cloudy) conditions. It also varies with the size and positions of windows and moreover it is just not possible to regulate the intensity of natural lighting. This necessitates the use of artificial lighting.

ADVERTISEMENTS:

2. Artificial lighting is designed in such a way that it should supplement natural lighting. Artificial lighting, during day time, serves only those areas which do not have enough light to work.

Artificial Light Sources:

(i) Tungsten filament lamps,

(ii) Fluorescent tubes, and

(iii) Mercury vapour lamps.

Tungsten filament lamps are inexpensive, easy to install and are available in different wattage ranges. But they have low rate of efficiency, need shielding to eliminate glare and therefore are used only for local lighting. They have been partly replaced by fluorescent lamps and tubes.

ADVERTISEMENTS:

Fluorescent lamps and tubes have best efficiency rate and are in very common use in factories. Their current consumption is less, they have a low brightness rating, longer life and are available in a number of colours.

However, sometimes they cause stroboscope effect when looking at rotating parts and create maintenance problems because they are being used in large number even in an average installation.

Mercury vapour lamps have a high brightness, are easy to maintain and have long operating life. Its greenish blue light gives an unnatural look. Mercury vapour lamps are used in large machine shops, hangers, and in high bays for general industrial lighting.

Reflectors may be employed for getting direct, diffused or indirect light.

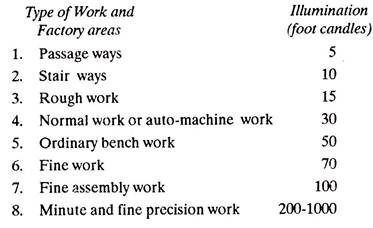

Levels of Illumination:

The unit used to measure the intensity of illumination is the lumen, I lumen/ ft2 being equal to a foot candle.

ADVERTISEMENTS:

Recommended standards of illumination for different types of work are given below:

Consideration # 7. Heating:

In a factory, heating is required for following purposes:

(i) Processing:

Heating is required for melting metals and alloys, making forging, etc.

(ii) Work-place heating:

ADVERTISEMENTS:

Work-place is heated for improving the efficiency of the workers in the winter season. The temperature maintained is within the comfort zone of about 60-65° F.

(iii) Cooking and preparation of factory meals.

Heat sources for:

(i) Processing:

Electric, coke or oil fired furnaces, boilers etc.

(ii) Workplace Heating:

Electric heaters, coal stoves etc.

(iii) Cooking:

Gas or electric stoves.

Fuel is generally burnt centrally and heat is transmitted to different work places, etc., with the help of pipes containing hot water, steam or hot air. Heating systems can be automatically controlled.

Consideration # 8. Ventilating:

Ventilating is basically replacing stale air (of the factory building) by fresh air. If the stale air is not removed, it will smell bad and the concentration of carbon-dioxide, humidity and temperature will rise. Inadequate ventilation results in discomfort and fatigue. Modern plants provide ample ventilation by increasing the number of air changes per hour.

Methods to provide ventilation:

(i) Natural ventilation through windows and roof or wall ventilators.

(ii) Mechanical ventilation, employing exhaust fans to extract stale air from the factory building. Fresh air enters from doors and windows.

(iii) Mechanical ventilation employing fans which draw fresh air into the factory building; the stale air escapes naturally.

Consideration # 9. Air-Conditioning:

Air-conditioning is the control of air temperature, humidity, cleanliness and distribution of air. Temperature control involves heating the air in winter and cooling it in summer. Heat may be generated from a central heating plant using hot water or steam as a heating medium. Cooling may be caused by piping the coolant from a centralized compressor plant to local areas where air is run through the coils. Self-contained air-conditioners may be installed directly in the rooms to be cooled. Humidity of the air is adjusted by adding moisture to it in winter and by removing moisture from the moist summer air.

Air is cleaned of foreign materials such as dust, etc., by:

(i) Forcing air through a spray of water,

(ii) Passing air through filters, and

(iii) Electrostatic precipitation.

Air motion is achieved by proper positioning of incoming air ducts and exhaust outlets. Odors and Bacteria in air are removed by passing air over chemicals.

Air-conditioning of buildings is done for the following purposes:

1. To avoid the precision measurement errors due to expansion of instrument parts.

2. To increase workability as in tobacco and textile industries.

3. To promote quality of workmanship.

4. To minimize deterioration as in meats, fruits, vegetables, certain oils and chemicals.

5. To increase employee efficiency, to reduce fatigue, to maintain morale and to create good public relations.

6. To increase output and improve product quality.

7. To reduce corrosion and deterioration of certain materials in process.

8. To protect workers against harmful dust (silica dust), smoke and poisonous gases.

9. To promote plant cleanliness and better psychological atmosphere.

Consideration # 10. Other Consideration, such as:

1. Good Appearance:

Good appearance can be achieved by making use of appealing colours, more glass and metal sections. The style of architecture and building materials are responsible for the good appearance of a factory building.

2. Strong, Durable, Economical and Safe Construction:

Make use of steel structures for roofing and supports. Use prefabricated doors, windows etc. Precast concrete construction may be advantageous.

3. Security Measures:

It include providing fencing wires, laying broken pieces of glass on the boundary walls, keeping explosive and inflammable materials outside the factory building in separate enclosures, etc.

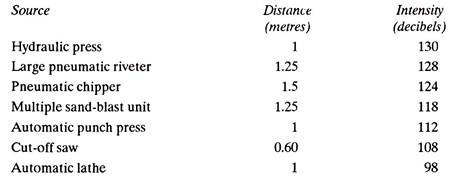

4. Noise Control:

Noise control i.e., minimizing undesirable noises to reduce mental fatigue of the workers (resulting in) accidents and industrial deafness.

A. Noise Affects:

i. Job performance,

ii. Health of employees, and

iii. Employees morale.

B. Sources of Noise in Industry:

Noise can be reduced by:

(i) Proper maintenance and lubrication of machines.

(ii) Isolating noise sources from other machinery.

(iii) Mounting machines on spring rubber or felt, etc.

(iv) Redesigning the plant for better acoustical properties.