After reading this article you will learn about the storage space requirements of a factory.

Adequate storage space allocation to different materials and supplies is of great importance because otherwise, a small increase in their quantities may give rise to congestion and the whole storage system maybe out of gear.

The following items and the amount of stock holding determine the storage space requirements:

(a) Incoming new materials,

(b) Checking and sorting the raw material,

(c) Inspection of raw material,

(d) Temporarily storing the new material before it is placed at the proper location,

(e) In-process inventory,

(f) Tools and other supplies, and

(g) Finished products.

The space to be provided for above factors depends upon:

(1) Size and weight of raw material, in-process goods and finished goods,

(2) Their quantities, and

(3) Frequency of use.

Liquid materials are stored in drums, cans, barrels and bottles. Gases are kept in cylinders whereas solid materials can be placed in boxes, barrels, bags, pallets, containers, etc. Castings or forgings can be stored in pallets and stocked in rows. Toxic materials are generally stored in well ventilated areas.

The storage space should be such that the materials can be quickly and easily taken out for delivery or stocked as soon as they are received in the factory. Suitable equipments can be used for handling the material. Bins, drums, barrels, racks, shelves, tanks, tote boxes, pallets, etc. may be usefully employed for storage purposes.

Storage space should be adequate, considering the material requirements and the load bearing capacity of the soil if heavy materials are to be stored. Aisles are passages for the movements of men and materials. Depending upon the type and size of the material to be stored, the amount and frequency of men movements and other traffic involved, and the size of material handling equipment, the aisles and the sub-aisles are designed. Generally aisles can be 1.5-3 metres wide and sub-aisles between racks may be 75 cm wide. The aisles should not have many turns or blind corners which may cause accidents.

A window as a part of the enclosed store space can be used for issuing salable and portable products, which can be passed on to the workers through the same so that operators can be kept outside the store room. It is very necessary for an effective store room control.

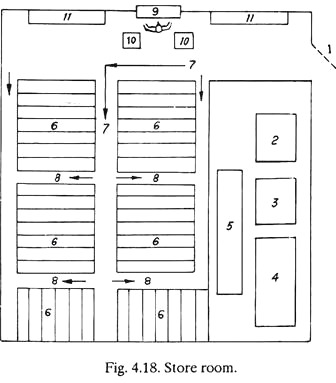

Figure 4.18 shows the plan view of a store room indicating various spaces required:

(1) Incoming material receiving gate,

(2) Place for dumping raw material,

(3) Place for sorting and checking of raw materials,

(4) Place for raw material inspection,

(5) Place for temporarily storing the materials before putting them on racks, etc.

(6) Proper place for storing each type of material,

(7) Main aisles,

(8) Side aisles,

(9) Service window,

(10) Boxes containing materials to be issued, and

(11) Counters for keeping materials, to be issued, which have been brought from (6) and will be placed in (10).