After reading this article you will learn about:- 1. Economic Aspects (Cost) of Accidents 2. Causes of Accidents 3. Prevention 4. Proneness.

Economic Aspects (Cost) of Accidents:

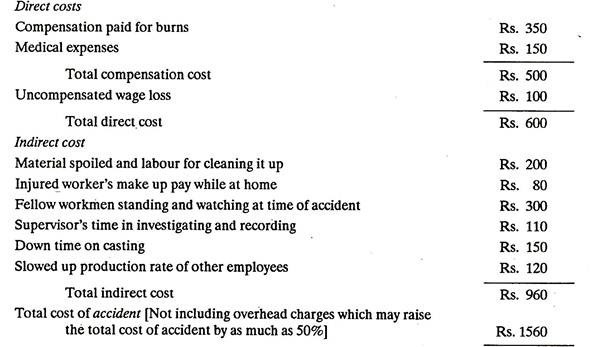

An accident can be very costly to the injured employee as well as to the employer of the concern. There are definite costs associated with the accident, e.g., direct and measurable costs and indirect, i.e., somewhat intangible but nevertheless real costs.

Direct costs of an accident they associate:

(i) Compensation insurance, including Payment, and Overhead costs.

(ii) Uncompensated wage losses of the injured employee,

(iii) Cost of medical care and hospitalization.

Indirect costs of an accident they associate:

(i) Costs of damage to equipment, materials and plant.

(ii) Costs of wages paid for time lost by workers not injured.

(iii) Costs of wages paid to the injured worker.

(iv) Costs of safety engineers, supervisors and staff in investigating, recording and reporting of accidents and its causes.

(v) Costs of replacing the injured employee.

(vi) Cost of lowered production by the substitute worker.

(vii) Cost of delays in production due to accident.

(viii) Cost of reduction in efficiency of the injured worker when he joins the concern after getting recovered.

And lastly the influence of accident on the morale of employees.

Example 1:

Cost of an accident. A foundary worker got burns on his foot while pouring molten metal from the ladle into the mold.

Causes of Accidents:

An accident is an unplanned incident and for each such incident there is usually a specific cause or causes if one could but discover them.

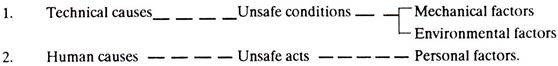

Accident may be caused due to:

Technical causes or unsafe conditions reflect deficiencies in plant, equipment, tools, materials handling system, general work environment, etc. Human causes or unsafe acts by the person concerned are due to his ignorance or forgetfulness, carelessness, day-dreaming, etc. It has been estimated that there are four accidents caused by human causes to everyone that is caused by technical causes.

Mechanical Causes or Factors:

1. Unsafe mechanical design or construction.

2. Hazardous arrangement (piling, over-loading etc.)

3. Improper machine guarding.

4. Unsafe apparel.

5. Defective agencies or devices.

6. Improper material handling.

7. Broken safety guards.

8. Protruding nails.

9. Leaking acid valve.

10. Untested boilers or pressure vessels.

Environmental Factors:

Environmental factors indicate improper physical and atmospheric surrounding conditions of work which indirectly promote the occurrence of accidents.

Environmental factors include:

1. Too low a temperature to cause shivering.

2. Too high a temperature to cause headache and sweating.

3. Too high a humidity (in textile industry) to cause uncomforted, fatigue and drowsiness (especially when the atmosphere is also hot).

4. Defective and inadequate illumination causing eyestrain, glares, shadows, etc.

5. Presence of dust, fumes and smokes (e.g., in foundary or welding shop) and lack of proper ventilation.

6. High speed of work because of huge work load.

7. More number of working hours and over and above them the tendency of the employer to insist for over-time work.

8. Inadequate rest pauses or breaks between the working hours.

9. Noise, bad odour and flash coming from the nearby machinery, equipment or processes.

10. Poor housekeeping.

Personal Factors:

1. Age.

2. Health

3. Number of dependents.

4. Financial position.

5. Home environment.

6. Lack of knowledge and skill.

7. Improper attitude towards work.

8. Incorrect machine habits.

9. Carelessness and recklessness.

10. Day-dreaming and un-attentiveness.

11. Fatigue.

12. Emotional un-stability, e.g., jealousy, revengefulness, etc.

13. High anxiety level.

14. Mental wordiness.

15. Unnecessary exposures to risk.

16. Non-use of safety devices.

17. Working at unsafe speeds.

18. Improper use of tools.

Accident Prevention:

Accident prevention is highly essential in an industry, in order to:

(i) Prevent injury to and premature death of employees.

(ii) Reduce operating and production costs.

(iii) Have good employer-employee relations.

(iv) High up the morale of employees.

Above all, prevention of accidents is a true humanitarian concern.

Accident prevention does not occur by itself; there should be consistent implementation of safety measures and safety programmes emphasizing the need for:

1. Safe Workplace Layout and Working Conditions:

Layout:

Although most accidents take place because of unsafe act of the employees, the role of the environments and surroundings cannot be ignored in determining the cause of accident. A good layout and working conditions play a major role in preventing many accidents which would have otherwise occurred.

For preventing accidents, the layout should be such that:

(i) Every employee has enough space to move and operate.

(ii) Passageways between working places, roads, tracks and alleys, etc. must never be obstructed.

(iii) It prevents the inrush of cold/hot air and draughts to the working place.

For adequate lighting, ventilation etc., the heights of the working rooms should be of 3 metres. Floors must be of nonskid type, satisfactorily plane and must possess such properties that they can be easily cleaned and absorb sounds. Windows should be of adequate dimensions in order to make full use of natural day light.

Doors and gates leading to open should be provided with guards, etc., to prevent draughts at the neighbouring workplaces. Fire hazards can be reduced by utilising fire walls to separate manufacturing area into several compartments. A worker operating on the machine should have easy access to the safety switches provided on the machine/near workplace.

Working Conditions:

In enclosed rooms, in order to have comfortable conditions, the following should be controlled. Air temperature, air purity, velocity of air, humidity of air, and heat radiations between bodies of different temperatures. Not only in enclosed rooms, even otherwise proper ventilation is a must if the manufacturing processes give rise to dust, smoke, fumes, etc.

Whether natural or artificial, there should be sufficient illumination, of adequate colour of light, continuous and uniform and free from glare. A high noise level at the workplace impairs men at work and may even endanger them. Noise develops from riveting, grinding, forging, engines, compressors etc.

To reduce noise level and to minimize detrimental effects (e.g., deafness) arising out of it:

(i) Select, purchase and make use of machines and processes which produce little noise.

(ii) Isolate and keep noise producing machines in separate closed cabins.

(iii) Use silencers to minimize the hissing sound of compressed air escaping from blow-off valves in pneumatic tools and machines.

(iv) Use suitable machine mounts to damp down the vibrations.

2. Safe Material Handling:

Careless handling of heavy materials and components is a major source of back and foot injuries. To avoid premature fatigue of transport workers, full use should be made of mechanised materials handling equipment. Use mechanical means of conveyance to ensure the safety of men engaged in material handling.

The transport workers should not be asked to lift more than the permissible load, e.g., for a boy of 16 to 18 years of age, this load is 19 kgs. During transport, sharp materials, sharp edged goods, poles etc., should be covered, placed in stable holders and retained by means of wire. Goods should be piled up such that they do not collapse due to impact or vibrations.

Containers or vessels employed to transport liquids or small parts:

(i) Should not be too large to limit the range of vision and impede lifting and carrying,

(ii) Should be light, and

(iii) Should not be defective/leaking.

Depending upon the condition of material, use a proper material handling equipment. All material handling equipment should be promptly repaired and adequately maintained on priority basis.

3. Personal Protective Devices:

(a) Protection of Head:

i. Safety hard hats.

ii. Rubberized hats for protection against liquids (chemicals).

iii. Ear protectors.

(b) Protection of Face:

i. Face mask.

ii. Face shields.

iii. Welding helmets.

(c) Protection of Eyes:

i. Goggles of case-hardened and clear glass for protection against impact.

ii. Eye cup goggles for protection against flying objects and dust.

iii. Eye cup goggles impervious to chemicals for protection against acids/alkalies splashes.

(d) Protection of Lungs:

i. Airline respirators.

ii. Cartridge respirators.

iii. Oxygen or air-breathing apparatus.

iv. Gas mask.

(e) Protection of Other Body Parts, e.g., Hand, Foot, Leg, etc.:

i. Protective asbestos clothing.

ii. Gloves.

iii. Safety shoes.

iv. Foot guards.

v. Safety body belt.

vi. Aprons.

vii. Safety (moulder’s) shoes.

4. Safety Measures Essential in Industry:

Other safety measures which may be adopted are:

a. Provide wire mesh safety guards to all rotating parts, e.g., pulleys etc.

b. High voltage equipment and other machines which cannot be properly guarded should be fenced.

c. Pressure vessels and their component parts (e.g., valves, gauges, etc.) should be periodically tested as per their specifications, the defective parts should be replaced.

d. Material handling equipment should have unobstructed paths to move on.

e. Defective tools, e.g., hammers, spanners, etc., should be immediately replaced.

f. Power should be switched off before repairing the equipment.

g. Inflammable material should be stored separately and away from the general store.

h. Electrical connections and insulation should be checked at regular intervals.

i. Fire extinguishers should be kept in proper condition and at key places.

To avoid electrical accidents:

(i) None except the electrician should be permitted to touch electrical connections.

(ii) All live wires should be isolated and insulated from each other.

(iii) Electrical connections and ground connections of all portable and un-portable machinery should be checked periodically.

(iv) Damp environmental conditions (floor etc.) should preferably be avoided.

Accident Proneness:

Examination of safety records often show that out of all the workers doing the same job and being subjected to the same physical environments, only a few have substantially more accidents than the rest. Such few workers who are found consistently to experience more accidents than the average (other) workers, are classified as ACCIDENT-PRONE workers/employees.

ACCIDENT PRONENESS may be defined as the continuing tendency of a person to have more accidents as a result of his persisting characteristics etc. Accident proneness is perhaps because of peculiar psychological and physiological make up of certain persons.

Causes of Accident Proneness:

(i) Un-attentiveness and day-dreaming.

(ii) Poor eyesight and hearing and lack of stamina.

(iii) Poor adjustment of work; distaste for the job.

(iv) Too much sensitivity and tendency to get perturbed easily, (Emotional stresses).

(v) Dislike of the supervisor/foreman, etc.

(vi) Lack of training, proficiency and skill to do a work.

(vii) Insufficient intelligence.

(viii) Unsafe behaviour of the worker (e.g., intentionally not using safety devices and safe practices).

Methods to Reduce Accident Proneness:

(i) Depending upon the job conditions select only those applicants who possess appropriate standards of physical and mental ability.

(ii) Transfer accident prone workers to comparatively less hazardous job situations.

(iii) Impart adequate training to a recruit before putting him on the job.

(iv) Encourage employees working under you and see that they do not get unnecessarily perturbed, frustrated or emotionally disturbed.

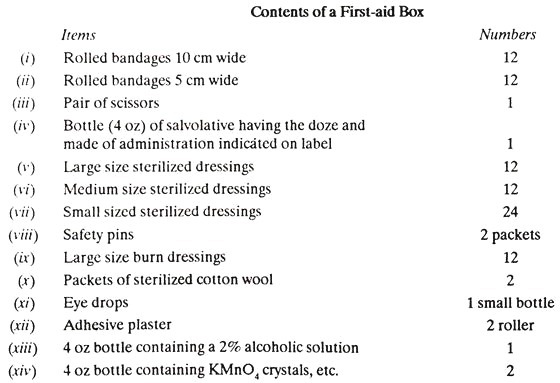

First-Aid:

Even after taking all safety precautions and measures, accidents occur in factories. An injured worker needs immediate proper treatment: in the absence of which, his condition may become critical.

To take care of such situations, factories employ full time, at least a person who has successfully completed his Red-cross first-aid course, and who can give preliminary treatment to the injured person, who may later on be taken to the hospital as the ambulance arrives.

Besides the above service, a first-aid personnel can look after those workers who get minor cuts, burns or electric shock. A first-aid box which contains the following is always kept ready during working hours.

Safety in Industry:

The modern safety movement started around 1912 with the First Cooperative Safety Congress and the organization of the National Safety Council in U.S.A. From 1912 to the present time, remarkable advances have been made in reducing the rate and severity of accidents.

The importance of industrial safety was realized because every year millions of industrial accidents occur which result in either death or in temporary and permanent disablement of the employees and involve a good amount of cost such as resulting from wasted man-hours, machine hours etc. In 1952 in U.S.A., fifteen thousand workers were killed in industrial accidents, 2,000,000 were injured and the total cost of these accidents was about $ 2,900,000,000.

Loss of lives and accidents costs gradually led to the formation of Factories act, Office, Shops and Railway Premises Act etc. The requirement for consideration of safety by management as part of its responsibility arises primarily from these Acts. Safety begins on the drawing board when in the original design of tools or workplace layout, accident hazard may be built in or eliminated.

Safety Results:

(i) From safe plant, processes, and operations, and

(ii) By educating and training workers and supervisors regarding safe practices on the shop floor.

In an industry, safety may be considered from the mechanical side (equipment, tools etc.) or from legal angles of workmen’s compensation or even as a matter of training in and motivation towards safe work practices for workers (especially newly recruited ones).

Need for Safety:

Safety in industry helps:

(i) Increasing rate of production.

(ii) Reducing production cost.

(iii) Reducing damage to equipment and machinery.

(iv) Preventing premature death of talented workers who are an asset to the society.

(v) Preventing needless pain and suffering to its employees.

Organization for Safety:

In a small concern each shop supervisor may be made responsible for safety in his shop. Each shop supervisor may report to top executive as regards safety matters. Since the shop supervisor has its main job to turn out production, he may treat safety as a secondary aspect. For this reason sometimes the safety function is taken care of by personnel officer or general foreman.

With the growth in the size of the industry and depending upon the hazardousness of processes/ operations, a full-fledged safety department may be created with the safety Director/Manager as its chief executive and a number of persons under him at different levels. The safety Director/Manager may be given a line position or staff position depending upon the conditions in the industry. Sometimes the responsibility for safety rests on a safety committee.

Safety Committee:

A safety committee may consist of executives, supervisors, and shop floor workers. Thus the lower level employees get a channel of communication on safety matters direct to executive level. It was observed that those organizations which made safety committees had lower record of accidents than those without safety committees.

Safety committees aid in developing safety consciousness as well as it is a policy making body on such safety matters as come before it. The Safety Manager/executive requires a degree of firmness and ready discrimination to exclude personal and union matters in which safety is merely the pretext for their airing. The safety executive should guard jealously the responsibilities of management and supervision.

Lastly, to get maximum out of a safety committee:

(i) It should be assigned specific problems and duties such as planning safety rules, publicizing them etc.

(ii) Its members should be asked to go on the shop floor and watch what is being done about it (i.e., the safety).

(iii) It should be asked to report periodically as what improvements have been made and what more can be done.

Safety Programmes:

A safety programme tends to discover when, where and why accidents occur. A safety programme aims at reducing accidents and the losses association with them. A safety programme begins with the assumption that most work-connected accidents can be prevented. A safety programme does not have an end; rather it is a continuous process to achieve adequate safety.

A safety programme tries to reduce the influence of personal and environmental factors that cause accidents. A safety programme involves providing, safety equipment and special training to employees.

A safety programme is composed of one or more of the following elements:

(i) Support by top management.

(ii) Appointing a Safety Director.

(iii) Engineering a safe plant, processes and operations.

(iv) Educating all employees to work safely.

(v) Studying and analysing the accidents to prevent their occurrence in future.

(vi) Holding safety contests, safety weeks etc., and giving incentives/prizes to departments having least number of accidents.

(vii) Enforcing safety rules.

A safety programme includes mainly four E’s (as explained above also):

(i) Engineering i.e., safety at the design and equipment installation stage.

(ii) Education of employees in safe practices.

(iii) Enlistment. It concerns the attitude of employees and management toward the programme and its purpose. It is necessary to arouse the interest of employees in accident prevention and safety-consciousness.

(iv) Enforcement, i.e., to enforce adherence to safety rules and safe practices.

Safety Instructions and Training:

This is essential for educating the employees to think, act and work safely so that the number of accidents can be minimized. Safety training/education gives knowledge about safe (and unsafe) mechanical conditions, personal practices and of the remedial measures.

Safety training involves:

(i) Induction and orientation of new recruits to safety rules and practices.

(ii) Explaining safety function, during, on the job training.

(iii) Efforts made by the first level supervisors.

(iv) Formulating employees safety committees.

(v) Holding of special employee safety meetings.

(vi) Displaying charts, posters, films etc., to emphasize the need to act safely.

Educating Employees to Develop Safety Consciousness:

A worker will usually accept the use of a safety measure if he is convinced of its necessity. Therefore, suitable measures should be adopted to increase the awareness of a need for safety in the environment of work.

Some such measures to develop safety consciousness among workers/employees are as follows:

(i) Display of safety posters and films to remind workers of particular hazards/accidents.

(ii) Providing simple and convenient safety devices.

(iii) Providing allowance (in the standard time) to the worker for setting, removing and replacing any necessary safety devices.

(iv) Ask the employee from the first day he starts work to adopt safety measures because a worker who has commenced work and has become familiar with it would never feel the need for safety measures at a later date.

(v) Hold safety competitions and award prizes to the winners.

(vi) Give due respect and recognition to safe workers and create in employees a feeling of pride in safe work.

(vii) Elaborate on the safety theme until all the employees are safety-conscious.

(viii) Hold regular safety meetings. They stimulate ideas and workers get more safety conscious as the time of meeting approaches near.

(ix) Lay out work areas to reflect safety considerations.

(x) Man information and literature pertaining to safety at the homes of all employees.

(xi) Report safety activities to all employees.

(xii) Welcome all safety suggestions.

(xiii) Cross-mark all accident areas.

(ix) Conduct safety training lectures periodically.