The work station design affects the production rates, efficiency and the accuracy with which an operation can be performed. A work station not only needs space for the worker and the machine, there are plenty of other items which also need accommodation.

Space requirements and a few more factors governing a good work station design, are described below:

(a) Space Requirements:

1. Space for the worker to stand, sit (as per requirements) or turn comfortably to operate the machine.

2. Space for the machine, taking into considerations the overhang, projection or the over-travel (OT) of the machine parts, like table of a milling machine or a planer.

3. Space for the work if it is projecting out from the machine like a long bar fed to a turret lathe.

4. Space for bins storing incoming material and processed goods.

5. Space for necessary tools and supplies required by the worker.

6. Space for additional attachments, accessories, or jigs and fixtures.

7. Space to load large work on and off the machines.

(b) Besides space requirements as given above other factors are:

1. Considerations of the space required, for the movements of material handling equipment.

2. Easy access to safety stops in case of emergency.

3. Easy access to machine for inspection, lubrication, maintenance and repairs.

4. Convenience of making foundations and machine installation.

5. Aisle space between one machine and the next.

6. Appropriate ventilating, lighting and safety arrangements.

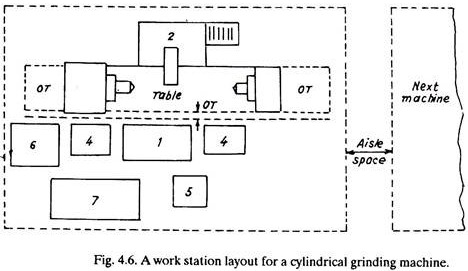

Figure 4.6 shows a work station layout, numbers 1, 2, 4, etc. refer to those of space requirements: