After reading this article you will learn about the duties and organisation of maintenance department.

Duties or Functions of Maintenance Department:

(A) Inspection:

(1) Inspection is concerned with the routine schedule checks of the plant facilities to examine their condition and to check for needed repairs.

(2) Inspections ensure the safe and efficient operation of equipment and machinery.

(3) Frequency of inspections depends upon the intensity of the use of the equipment. For example, belts in a machine may be checked every week; furnace equipment every month; an over-head bridge crane every four months and so on.

(4) Inspection section makes certain that every working equipment receives proper attention.

(5) Items removed during maintenance and overhaul operations are inspected to determine the feasibility of repairs.

(6) Maintenance items received from vendors are inspected for their fitness.

(B) Engineering:

(1) Engineering involves alterations and improvements in existing equipment and building to minimize breakdowns.

(2) Maintenance department also undertakes engineering and supervision of constructional projects that will eventually become part of the plant.

(3) Engineering and consulting services to production supervision are also the responsibilities of maintenance department.

(C) Maintenance (including Preventive Maintenance):

(1) Maintenance of existing plant equipment.

(2) Maintenance of existing plant buildings, and other service facilities such as yards, central stores, roadways, sewers, etc.

(3) Engineering and execution of planned maintenance, minor installations of equipment, building and replacements.

(4) Preventive maintenance, i.e., preventing breakdown (before it occurs) by well-conceived plans of inspection, lubrication, adjustments, repair and overhaul.

(D) Repair:

(1) Maintenance department carries out corrective repairs to alleviate unsatisfactory conditions found during preventive maintenance inspection.

(2) Such a repair is an unscheduled work often of an emergency nature, and is necessary to correct breakdowns and it includes trouble calls.

(E) Overhaul:

(1) Overhaul is a planned, scheduled reconditioning of plant facilities such as machinery, etc.

(2) Overhaul involves replacement, reconditioning, reassembly, etc.

(F) Construction:

(1) In some organizations, maintenance department is provided with equipment and personnel and it takes up construction jobs also.

(2) Maintenance department handles construction of wood, brick and steel structures, cement and asphalt paving, electrical installations, etc.

(G) Salvage:

Maintenance department may also handle disposition of scrap or surplus materials.

This function involves:

i. Segregation, reclamation and disposition of production scrap, and

ii. The collection and disposition of surplus equipment, materials and supplies.

(H) Clerical Jobs:

Maintenance department keeps records:

i. Of costs,

ii. Of time progress on jobs,

iii. Pertaining to important features of buildings and production equipment; electrical installations; water, steam, air and oil lines ; transportation facilities (such as elevators, conveyors, powered trucks, cranes, etc.), etc.

(I) Generation and distribution of power and other utilities.

(J) Administration and supervision of labour force (of maintenance department).

(K) Providing plant protection, including fire protection.

(L) Insurance administration.

(M) Establishing and maintaining a suitable store of maintenance materials.

(N) Janitorial service.

(O) Housekeeping.

Good housekeeping involves upkeep and cleaning of equipment, building, toilets, wash-rooms, etc.

(P) Pollution and noise abatement.

Organisation of Maintenance Department:

(1) The buildings, plant and services are called by the accountant fixed assets and in many companies they form at least 50% of the money invested.

In any company, small or big, it is therefore essential that some part of the main organization should be responsible for maintaining these important assets.

(2) The section or department which preserves and looks after the upkeep of equipment, building etc., is called maintenance department.

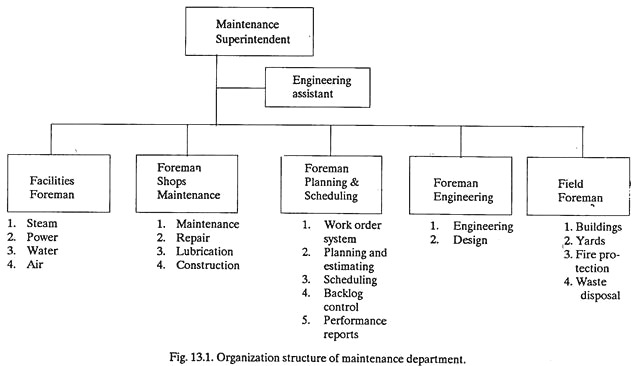

(3) To work satisfactorily, the maintenance department has an organization structure.

Fig. 13.1. Organization structure of maintenance department.

(4) A few basic concepts of good organisations that should be kept in mind in developing an organisation are:

(a) A reasonably clear division of authority with little or no overlap.

(b) Vertical lines of authority and responsibility should be kept as short as possible. In other words, a level which simply transmits information up and instructions down should be eliminated.

(c) Keep optimum number of persons (3 to 6 is the average value) reporting to an individual.

(d) Fit the organisation to the personalities involved. This means that the organisation structure should be flexible and it may be revised periodically to fit changing personnel and conditions.

(5) The basic organisation structure of maintenance department depends upon:

(a) Types of maintenance activities to be looked after:

The wider the maintenance field to be covered, the bigger is the organisation.

(b) Continuity of operations:

The size of the maintenance force and therefore the structure of maintenance organisation depend upon:

i. Whether it is a four, five or six working days week, and

ii. Whether the plant runs in one, two or three shifts.

(c) Size of the plant:

The organisation structure of the maintenance department varies with the size of plant. The larger the plant the more the number of persons in the maintenance force.

(d) Compact or dispersed plant:

A plant spread in a wider area (like ECIL Hyderabad) needs decentralization and may require several parallel maintenance organisations. A compact plant may need only one such Organisation.

(e) Nature of industry, i.e., whether it is primarily an electrical, electronics, chemical or a mechanical industry.

(f) State of training and reliability of work force.

(6) In establishing a maintenance organisation, it is essential to recognize that:

(a) The plant is to be maintained at a level consistent with low cost and high productivity;

(b) Supervisors should be appointed according to the duties and responsibilities involved; and

(c) Modern age indicates greater need of newer engineering techniques and skills.