After reading this article you will learn about:- 1. Introduction to Replacement of Equipments 2. Reasons for Replacement of Equipments 3. Factors to be Considered.

Introduction to Replacement of Equipments:

In replacement, one is concerned with equipment and machinery that deteriorates with the passage of time. Since over time, an equipment ages, every piece of equipment in an industry is a candidate for replacement. However, with increasing maintenance, the productive life of an equipment can be increased but the maintenance cost goes high.

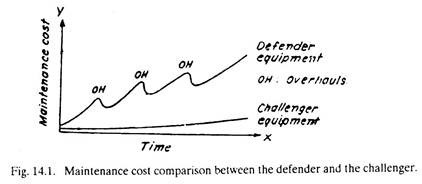

Fig. 14.1 shows the maintenance costs per unit time of the presently owned equipment called the Defender and the new equipment (under consideration for replacing the present equipment) hereafter known as the challenger.

Replacement whereas reduces (equipment) maintenance cost, it involves a high average capital cost. It is decided to replace an equipment when the maintenance and capital costs of the defender equipment is more than the average capital and operating costs of the replacement, i.e., the challenger equipment.

Many people feel that equipment should not be replaced until it is physically worn out. But it is not correct; preferably equipment must be constantly renewed and updated (taking financial aspects into consideration) otherwise there is increasing risk that it will become obsolete.

In recent years manufacturing management has given serious thought to the policies for equipment replacement. The new trend is to replace all those equipment which are not operating as productively as possible. For example, a lathe which cannot produce jobs as per the desired surface finish and dimensional tolerance or if it cannot make use of the capabilities of the newer cutting tool materials, should be replaced.

Reasons for Replacement of Equipments:

Equipment are generally considered for replacement for the following reasons:

(a) Deterioration:

Deterioration is the decline in performance of an equipment as compared to a new equipment identical to the present one.

Deterioration may occur due to equipment wear and tear, misalignments, etc., Deterioration:

(i) Increases maintenance costs;

(ii) Reduces product quality;

(iii) Decreases rate of production;

(iv) Causes loss in operating time;

(v) Increases labour costs; and

(vi) Reduces efficiency of the equipment.

(b) Obsolescence:

Technology is progressing rapidly; newer and better equipment are being developed and turned out every year.

If management of a concern does not go for a change in the equipment or machinery, the unwarranted manufacturing costs arising from obsolete equipment will:

(i) Reduce profits; and

(ii) Seriously impair the concern’s competitive position in the market.

A first class machine, but producing only 15 pieces per hour is rendered obsolete in spite of its excellent mechanical condition, when another new machine capable of satisfactorily producing 100 pieces per hour comes into the market; because with the new machine cost per piece produced is much lower. Obsolescence causes loss in value of machinery.

(c) Inadequacy:

When an existing equipment becomes inadequate to meet the challenge of making new products or existing product in large quantities, the question of replacement arises. An existing pit furnace may be melting gray cast iron till present in a foundry, but huge orders necessitate its replacement by a cupola.

The pit crucible furnace is inadequate to boost the production rate. A milling machine may not become obsolete, but it is inadequate in producing gears on mass production. Under such conditions one may go for automatic gear cutting machines and form cutters.

(d) Working conditions:

It may be thought of replacing old equipment and machinery which create unpleasant (i.e., smoky, noisy, etc.) and hazardous working conditions causing worker un-safety and leading to accidents.

Factors to be Considered for Replacing Equipment:

Two main factors are:

(a) Technical factors:

They tend to consider:

(i) Whether the present equipment has deteriorated, i.e., whether it is functioning properly or not?

(ii) Whether the present equipment has become obsolete?

(iii) Is the present equipment inadequate in meeting production rate?

(iv) Can the present equipment hold tight tolerances?

(v) Can the present equipment provide required surface finish?

(vi) Is the new equipment better designed from a method’s standpoint?

(vii) Is the present equipment polluting or spoiling working conditions of the factory?

(viii) Is the present equipment making more noise and vibrations and thus distracting the attention of the workers?

(ix) Is the existing equipment hard on the workers?

(x) Does the existing equipment increase likelihood of accidents?

(xi) To what extent the existing equipment is not capable of making use of the newer developments in the field?

(xii) How often the existing equipment needs maintenance and repairs?

(b) Financial factors:

They are:

(i) The initial cost of the challenger.

(ii) Operating expenses:

They include:

(a) Direct and indirect labour cost,

(b) Direct and indirect material cost,

(c) Power,

(d) Maintenance cost,

(e) Cost of replacing parts,

(f) Insurance, and

(g) Interest on invested capital, etc.

(iii) Expected salvage value at the end of the service life.

At the time of replacement, rather than considering only the factors pertaining to the particular equipment involved, replacement studies should be carried out on plant-wide cost basis because the effect of replacement upon other operating costs may be highly significant.