After reading this article you will learn about the types and construction of factory building.

Types of Factory Buildings:

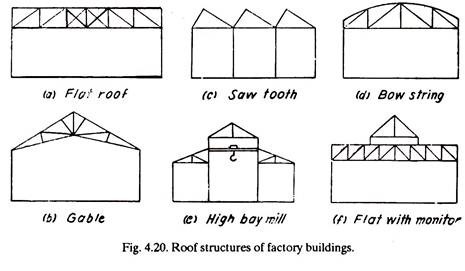

Factory buildings may be classed as follows (refer Fig. 4.20):

1. Single Storey Buildings:

Single storey factory buildings with different roof structures such as flat, bow string, etc.

Advantages:

(a) Easy to expand.

(b) Greater flexibility in layout.

(c) Natural light and ventilation can be supplied through the roof.

(d) Foundations required to be made are light.

(e) A single storey building requires less time to erect.

(f) Since floor to floor movements are not involved, material handling costs are lower.

(g) One floor level makes supervision and control easier.

(h) Less mechanical vibrations are involved.

(i) Heavy machinery can be installed.

(j) It is easy to isolate abnoxious or hazardous areas.

(k) No space is lost due to elevators and stairs.

(l) Building costs are less compared with a multi-storey factory of the same gross area.

(m) Permits high ceilings.

(n) Needs fewer columns.

(o) The risk of serious fire damage is less.

(p) Involves less operating cost.

(q) Maintenance of building and equipment is easy.

Disadvantages:

(a) Single storey factory buildings do not make most effective use of land.

(b) They need more land.

(c) Layout is not very compact.

(d) Gravity cannot be employed for material handling purposes.

(e) Valuable production floor space is occupied by offices and stores.

Use:

Single storey factory buildings are used where:

(i) Land is relatively cheap.

(ii) Heavy machinery is required for processing.

(iii) Growth of factory is expected.

2. High Bay and Monitor Type Buildings:

They are basically single storey buildings. For a given floor space, they provide maximum overhead space. Large overhead space can be utilised for operating cranes. Natural ventilation and natural illumination are the main advantages for these types of factory buildings. Foundry and steel mill buildings are generally of monitor or high bay type.

3. Multi-Storey Buildings:

Advantages:

(a) They possess distinct material handling advantages where goods can be moved by gravity.

(b) They provide for maximum operating floor space per square metre of land.

(c) They involve a lower site cost for a given production area.

(d) They need less land and make more efficient use of land.

(e) They make a more compact layout.

(f) They involve lower heating costs.

(g) Top stories may be utilised for light stores and offices thereby increasing the size of production floor on the ground level.

Disadvantages:

(a) Material handling is expensive for bulky materials.

(b) More time is taken by persons and materials in transit from one floor to another.

(c) Stairways, elevators, etc. reduce the effective area and thus increase the cost per square meter of usable space.

(d) The more the number of stories, the higher is the cost of foundations and the more is the space occupied by supporting columns.

(e) Natural illumination in the centre of a multi-storey building is poor.

(f) Changes in width and length of upper floors (for expansion purposes) is not possible.

Uses:

Multistory factory buildings are used:

(i) Where cost of land is relatively high.

(ii) In process industries such as refineries, chemicals, fertilizers, floor mills etc.

4. Buildings of Special Types:

Special type buildings may be a combination of the three types discussed above. A special type building may be designed to accommodate a particular process. Such buildings are inflexible. They become obsolete, once the process changes.

Types of Building Construction:

An industrial building may have one of the following constructions:

(a) Wood Frame Construction:

Such a building generally is not more than two storeys in height. Floors take lighter loads only. It is highly flammable construction, therefore it is used where fire hazards are rare and are not a serious drawback. Such a building depreciates fast and thus has relatively shorter life. High insurance rates are associated with such construction.

(b) Brick Construction:

Side walls and interior fire walls (i.e., the walls which separate sections of the building to prevent fire spread) are made up of bricks. Floor beams and roof supports resting on the walls are pilastered. It lasts longer than wood construction and facilitates making changes, if any.

(c) Slow Burning Mill Construction:

It is plank-on-timber building with load bearing brick siding. Owing to heavy wood members being used, the construction is fire-resistant because the members, i.e., pillars, etc., are slow to burn and even after getting partially charred, support the building (i.e., floors etc.). Such a factory building can take moderate floor loads but involves high maintenance costs, high noise and vibration transmission and light and ventilation restricted by the load bearing walls. However, electrical, plumbing and other plant utilities can be altered with ease.

(d) Steel Frame Construction:

It makes use of steel girders, columns and trusses. Space between the columns is filled by bricks, etc. Such a construction involves a low insurance rate and facilitates making changes in the building.

(e) Reinforced Concrete Construction:

This is fire-proof construction. All structural members are made up of reinforced concrete, masonry or steel encased in concrete. It is a very good type of construction for multi-storey buildings. Such construction provides heavy floor loading characteristics and involves low maintenance costs. Of course the initial cost of construction is high. Changes in buildings are costly and difficult to make.

(f) Precast Concrete Construction:

It is very speedy and economical. Sections are precast either at vendor’s end or on the ground itself, cured (i.e., set) and then tilted vertically up by cranes to form the wall, roof and floor, etc.

Materials Required for Building Construction:

For floors:

1. Concrete: It is cheap and serviceable; is very commonly used.

2. Wood blocks laid on concrete.

3. Vinyl-asbestos tiles laid on concrete.

4. Grease resistant asphalt tile.

For Walls:

1. Cement.

2. Brick.

3. Tiles.

4. Concrete.

5. Wood.

6. Insulated metal panels.

7. Asbestos cement panels.

A combination of brick and cement is very popular.

For Roofs:

1. Steel trusses, (refer Fig. 4.20).

2. Iron, brick and cement construction (flat roofs).

3. Wood construction etc.