In this article we will discuss about the concept of industrial value chain, explained with the help of a diagram.

The technological environment is fast changing all over the world due to competition. There is, thus, a need to find improved solutions to problems.

These changes demand increased emphasis on activities like quality, material utilisation, machine availability and use in manufacturing, and indigenous research and development. Against this background, a systematic and in-depth analysis of an ‘industrial value chain’ is considered a strategic move for a firm.

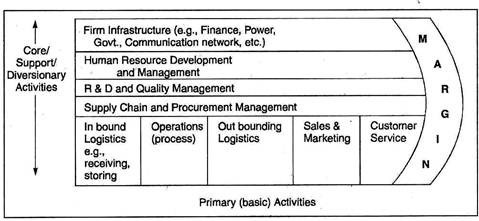

The concept of industrial value chain can be better understood through the model below:

Through the performance of the above kind and nature of activities, the firms create ‘values’ for their customers. So, it is useful to think of the end-use of a product or service as delivering value to the customers and the business unit as a collection of ‘value’ generating activities.

The value chain is about the creation of value, not just the addition of cost and margin. It is considered strategically important as it helps in identifying and measuring the value-creating activities.

The value chain framework is broader in scope and highlights four profit improvement areas:

(i) Linkage with suppliers;

(ii) Linkage with customers;

(iii) Linkage with processes and operations; and

(iv) Linkages across business unit value chains (as shown in the above model) within the firm.

Careful management of linkages is the decisive source of competitive edge.

The value chain analysis with a cost reduction perspective (to create and sustain a competitive advantage) involves the steps as follows:

(i) Identification of industry’s value chain and assigning costs, revenues, and assets to value activities

(ii) Diagnosing the cost drivers regulating each value activity (both structural cost drivers and operational cost drivers).

(iii) Developing sustainable competitive advantage either through controlling cost drivers better than the competitors or by re-configuration the value chain.

The value chain identifies the distinct strategic activities, analyses them and their respective cost drivers and addresses to the following key questions from strategic view point:

(i) Can a firm reduce costs in particular activity, holding the value (arising from external/internal customers) constant?

(ii) Can a firm increase the value in this activity, holding the costs constant?

(iii) Can a firm reduce assets in this activity, holding costs and revenues constant?

(iv) Is there any surplus facility (spent but unutilised resources) that can create value?

The value chain analysis enables a firm to understand and focus on the aspects like:

(i) Cause of the activity;

(ii) Resource consumption by the activity; and

(iii) activity linkage.

Knowledge and analysis of the above three factors brings opportunities for process redesign with a view to reducing the cost of the process.

This analysis points out:

(i) If there is any complexity of the activity,

(ii) If there is any duplication of the activity,

(iii) If there is any alternative way of doing the activity so that it will consume lesser resource,

(iv) If there any activity which is performed with no contribution to the process objective (i.e., no ‘value’ adding),

(v) If there is any activity, when added in between two activities, that will increase the overall process value.

Again, the three-tier classification of activities into core/support/diversionary categories facilitates analysis that helps a firm to meet different competitive situations. When the ‘micro-activities are identified and analysed with regard to their cost effectiveness, the management gets insights into the areas where Unnecessary activities can be dropped or their costs can be reduced.

The benefits of ‘Value Chain Analysis’ are immense.

These are as follows:

(i) It highlights the cost of activity, e.g.,

Does the employee at the time of causing an activity know its cost?

Does the salesman know the cost of each order processing?

Does the scheduling manager know the cost per batch?

(ii) It encourages new thinking towards process improvement, e.g.

How can the activities be carried out to improve efficiency?

(iii) It links to Total Quality Management programmes as the activity cost can be related to the service level achieved.

(iv) It facilitates cost cutting by taking activity levels into consideration, and thus making cost targets more realistic to achieve.

(v) If enables trend analysis and ‘benchmarking’ of costs to take place.