After reading this article you will learn about the design of work station and work place layout.

Design of Work Station:

“Work station” or “Work place” may be defined as the floor space occupied by the worker and machine or group of machines.

In the design of work station layouts, generally following space requirements are taken into consideration:

(i) The rectangular space occupied by the length and width of the machine or group of machines. This should include the space for the travel of moving parts and for projected machine parts such as cover, wheels, shafts, levers, doors, pulleys, handles etc.

ADVERTISEMENTS:

(ii) Floor space for the power source or say electric motor when placed on the floor or within the working area.

(iii) Floor space required by the workers to perform work.

(iv) Clearance space for feeding the work on and off the machine.

(v) Space for racks, conveyor stations, bins etc. which either contain the work to be processed or receive the work after it has been processed on the machine.

ADVERTISEMENTS:

(vi) Space for tool racks, work benches, auxiliary equipment etc. required by the individual machine, if any.

In addition, the work station needs much more space and equipment than the machine indicates. Hence enough floor space for individual machine should be left aside while making plant layout.

Storage Space Requirement:

In plant layout, while allotting space for work stations provision must be made for material storage space essentially required inside the plants. For waiting processing or moving from one area to the next area, every area or department must have a space required for such purpose.

The space requirement depends on various factors, such as:

ADVERTISEMENTS:

(i) The quantity of raw materials required to be used per hour.

(ii) Volume and weight of semi built parts awaiting move from one machine to the next machine.

(iii) Volume and weight of parts on the move from one department to next department.

(iv) Volume and weight of scrap.

ADVERTISEMENTS:

(v) The ceiling height of the plants building.

(vi) Total production per assembly.

(vii) The load bearing capacity of floor.

(viii) The raised ground required for storage.

ADVERTISEMENTS:

(ix) Methods to be adopted for storage purpose.

When the total space required for all the machines has been estimated, provision must be made for employee’s service facilities such as canteen, first aid, drinking water, rest room, waiting room, washing places, urinals, sales department, personnel department office, store keepers enclosure etc.

Design of Work Place Layout:

Bad working conditions always affect the productivity adversely. It has been established that comfortable work place will keep workers more satisfied and more will be the productivity. Hence while designing a work place environment and such other factors must also be considered.

The science which considers all these factors is known as “Ergonomics”. Ergonomics combines the knowledge obtained from the study of anatomy, physiology, psychology etc. to reduce the stress (like fatigue, eye strain, mental and muscular fatigue) on the worker in his work area.

ADVERTISEMENTS:

While designing the machines and equipment, efforts are made to reduce these stresses and thus study on human and machine becomes necessary. Thus the job of machine design is conducted by an ergonomics team which consists engineers, designers, anatomists, physiologists and psychologists (in small industries this work is generally carried out by work study team).

Following are some of the important elements which are related to the work place:

1. Cleanliness:

As cleanliness effect on the workers’ efficiency hence the working place must be clean. For this purpose care must be taken to provide a suitable place for everything connected with the job and worker must be asked keep everything in its place. Work area must be clean and well painted.

ADVERTISEMENTS:

2. Proper Illumination:

Work place must be properly illuminated (illumination of proper intensity) so to avoid eye strain. Care must be taken to avoid glaring, flickering. Colour of light selected must reduce eye fatigue.

3. Noise:

A work place must be selected so as to have as less noise as possible. Experiments have shown that reduction in noise result in the increase of efficiency with lesser fatigue.

4. Location for Tools and Materials:

All tools and materials required by a worker must be located within the normal grasp area and as far as possible in front of the worker. These tools and materials when placed as near to the worker as possible, he will have to travel lesser distances to take these tools and materials again and again and then put them at their desired places which otherwise will be the loss of energy and time.

ADVERTISEMENTS:

For the assembly work, it advisable to provide such arrangement so that the components can slide along the smooth surface and the worker picks them up. It will greatly reduce the time and effort.

5. Proper Chairs:

Chairs permitting proper posture for the workers must be provided. This is possible when the worker is working on the work bench (e.g., assembly, fitting an inspection etc.). Performing a job on floor in sitting position or on table in standing position requires more energy.

The height of chair and of the work bench must be arranged in such a way so that the worker may not feel any difficulty while working. Their height must be such that the top of bench remains at the height of the elbow of the worker. If possible the height of the bench must be such that worker can work both in fitting and standing position. Chairs must be provided with foot rests.

6. Work Bench:

ADVERTISEMENTS:

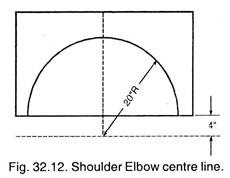

All the tools and materials must be located within the normal grasp area and as close in front of the operator as possible. Experiment have shown that a semi-circular table having a radius of 20″ or 50 cm from a point at 4″ or 10 cm back (4″ or 10 cm back gives approximately centre line of the operator shoulders and elbow) as shown in the Fig. 32.12, follows a most comfortable position.

The work bench must be so designed so that both hands can be used simultaneously.

7. Designing Machines:

When a worker operates or uses a machine, instrument or tools, it is essential that man-machine must be considered as a single working unit from the design points of view, as explained above.

Machine must be so designed that worker can use both hands and foot simultaneously for operating it and all the levers, pedals, instruments, hand- wheels, knows and buttons must be located within the normal grasp at a suitable height and in front of the operator. Foot pedals must be provided with suitable returning springs. Care must be taken to avoid eye strain, muscular and mental strain.

Space Requirement:

Space requirement for production mainly depends on the sum of the areas of individuals work places. An allowance is added to this, to provide aisles and other non-productive areas. Total production space is determined after determining the areas for all work places, machines and operators engaged for each operation or activity.

ADVERTISEMENTS:

Work place area is determined by designing the work place to include the following with the overall objective of determining as to how the personnel should be integrated into the production process:

1. Material,

2. Operator,

3. Machines and other auxiliary equipment,

4. Tools, and

5. Utility services.

Factors Considered in Designing a Work Place:

ADVERTISEMENTS:

While designing a work place, designer should follow the principles of motion economy and work place design.

It should consider the following factors:

1. Direction of flow of material or activity.

2. Items to be kept in the workplace e.g., machine, bench, stock containers, and conveyors.

3. A sketch is prepared indicating the equipment, direction of material flow indicating the sources and destination of material. Area and relative positive of each of these should be indicated in the sketch drawn to the scale.

4. Waste and scrap disposal route.

ADVERTISEMENTS:

5. Path of material handling equipment indicating the area needed.

6. Distances between items in the workplace are indicated on the sketch drawn as mentioned above.

Characteristics of Material Handling at Workplace:

1. The distances involved are short as compared to those in traditional material handling.

2. Number of cycles performed is high.

3. Always there is a scope for improvement in handling activity at the workplace.

4. Handling at workplace is categorised as direct labour.

5. A large proportion of cycle time is consumed in handling.

Work Area Planning:

While planning a work area, following points should be kept in view:

1. Area required by machine while it is in operation.

2. A fixed location for tools, gauges, incoming material and outgoing material.

3. Use of gravity feed where possible.

4. Arrange material so that it is not required to be re-position.

5. Adequate means and system for removal of scrap.

6. Leave sufficient space for material supply, storage and delivery.

7. Select appropriate handling equipment.

8. Minimise walking by operator.

9. Machines should be placed in such a way, so that lubrication or repairs is not difficult.

10. Location of aisles, lifts, elevators etc. be considered.