After reading this article you will learn about the meaning of line balancing in plant layout.

Meaning of Line Balancing:

“Line Balancing” in a layout means arrangement of machine capacity to secure relatively uniform flow at capacity operation.

It can also be said as “a layout which has equal operating times at the successive operations in the process as a whole”. Product layout requires line balancing and if any production line remains unbalanced, machinery utilisation may be poor.

Let us assume that there is a production line with work stations x, y and z. Also assume that each machine at x, y and z can produce 200 items, 100 items, and 50 items per hour respectively. If each machine were to produce only 50 items per hour then each hour the machines at x and y would be idle for 45 and 30 minutes respectively. Such a layout will be unbalanced one and the production line needs balancing.

As an another example, a bakery would not be in balance, if the oven continuously baked loaves at the rate of 600 per hour and wrapping machine could only wrap 400 loaves per hour Hence the production line requires balancing.

Methods of Line Balancing:

(i) The one possibility in the right direction, as far as balancing the line is concerned, would be to increase the output.

(ii) The second possibility is that another product may be sent close to the first one so that some idle machines may be used jointly.

(iii) The third possibility may be to estimate the output of the last work station. This can be taken as the minimum output of all the intermediate work stations.

A balanced layout eliminates bottleneck operations as well as preventing the unnecessary duplication of equipment capacity. Line balancing is a major consideration in layout because a lack of balance can most easily hinder the production.

For balancing it is not essential that output of each operation should be same but the essential is to see that output of fastest machine should be multiple of the output of the remaining other machines.

Example 1:

A product requires 4 operations on 4 work stations in line.

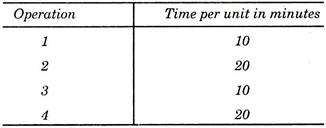

The operation time per unit is as follows:

The total working hours per month are 150. The required production is of 450 units per month. Suggest how the time should be balanced for maximum utilisation of machines. What percentage of each machine time is idle?

Solution:

Working hours/month = 150 = 150 × 60 minutes = 9000 minutes

Production/month = 450 units

Time/unit = 9000/450 = 20 roman minutes

In the question operation time for the last operation 4 is 20 minutes, on the basis of this last operation work station utilisation can be calculated.

In this question work station 2 i.e., operation 2 also consumes 20 minutes.

Therefore, Work station No. 2 and 4 are 100% engaged while work station No. 1 and 3 are 50% engaged.