The following article will guide you about how to manufacture:- 1. Paint 2. Varnish 3. Lacquer 4. Distemper 5. Resins and Emulsions 6. Bituminous Paint.

1. Paint Manufacture:

In general, the manufacture of paint requires the following steps:

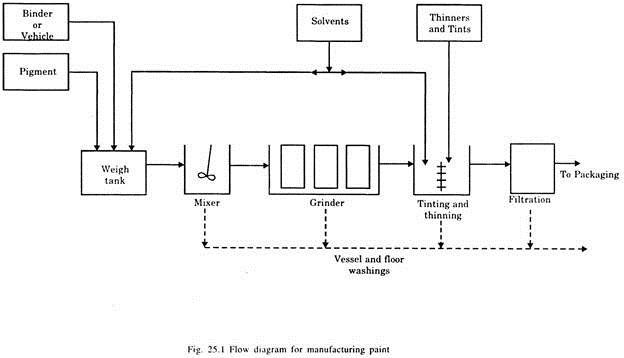

Dry pigments are weighed, mixed and fed through hoppers or chutes into mills where they are dispersed in an appropriate resin vehicle. The milled pigment is transferred to a mixer where thinners, drying agents, etc., may be added to adjust consistency, viscosity, colour and drying time. When mixing is complete, the paint is filtered through filter cloth and packed into containers (Fig. 25.1).

2. Varnish Manufacture:

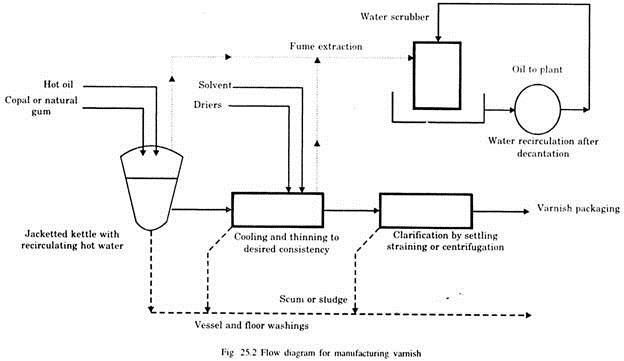

Varnish is an un-pigmented resinous surface coating. In traditional varnish manufacture an open kettle is set over a fire in which copal or other natural gum is heated and dissolved in hot oil. Other ingredients such as driers are added and after cooling the varnish is thinned out to a workable consistency with solvent.

It is then clarified by gravity settling, straining or centrifugation. Modern manufacture takes place in jacketed enclosed kettles. The decomposition products of resin and oil released as fumes are removed through an exhaust system where the fumes are scrubbed by jets of water spray. The fume oil is separated from the water by decantation and the water is recirculated (Fig. 25.2).

3. Lacquer Manufacture:

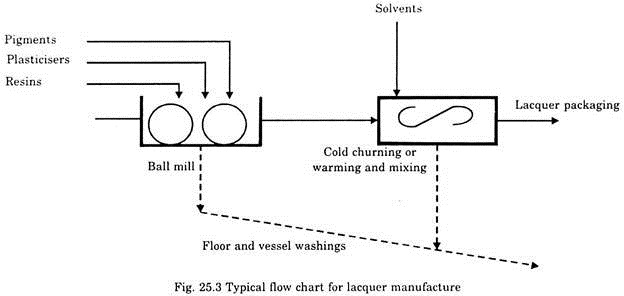

Lacquers are coating that dry only by evaporation. The pigments are first dispersed in ball mills with plasticisers and natural or synthetic resins are added. Solvents are added to achieve required consistency. This may be done either by cold churning or by gentle warming and mixing (Fig. 25.3).

4. Distemper Manufacture:

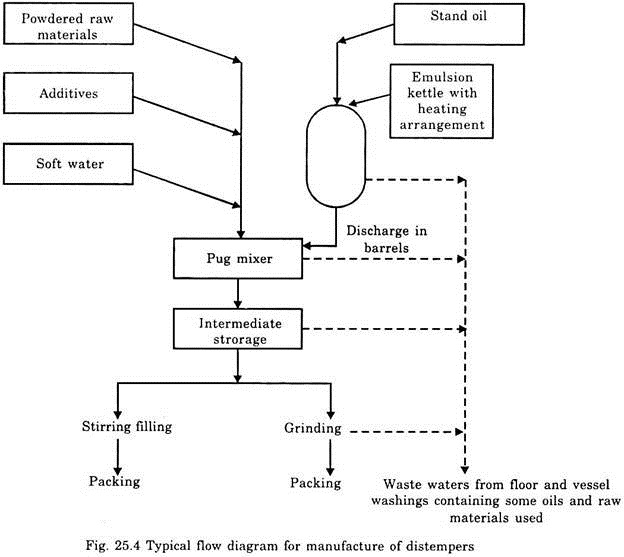

Powdered raw materials together with additives go to pug mill in which soft water is used. Other raw materials are emulsified with stand oil prior to entering the pug mixer. Further grinding may be done before packing (Fig. 25.4).

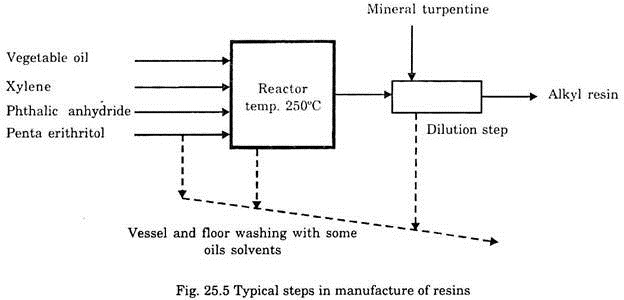

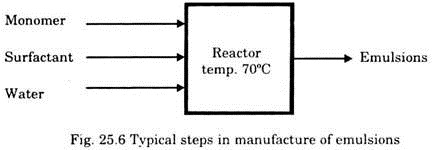

5. Manufacture of Resins and Emulsions:

Other items of interest in paint manufacture are resins and emulsions for the manufacture of which various chemicals/substances are reacted at controlled temperatures in special reactors. (Figs. 25.5 and 25.6).

6. Manufacture of Bituminous Paint:

Bituminous paint is manufactured in synthetic resin plants. The process followed is almost identical to that of resin manufacturing process. The bitumen (generally maxphalt grade of tar is used) is melted in a closed, jacketed kettle.

Heating is done indirectly by circulating thermic fluid around the kettle, at a temperature of 150-180°C. Bitumen is melted in the kettle in 2 hours’ time. During the heating process fumes are given out which are passed through a water scrubber. This water is let out into the drains from where it is finally collected and treated in the effluent treatment plant.

Melted bitumen is then thinned down to the required consistency by mineral turpentine, filtered and cooled. Bituminous paint is manufactured at M/s. Garware Paints Ltd., Thane, Maharashtra and for production of 6000 lit/month, wastewater generated is approximately 1000 lit/month. Bituminous paint is used as anticorrosive coating for water tanks, underground pipes etc.

Coal tar enamel is composed of specially processed coal tar pitch combined with an inert mineral filler. The enamel contains no asphalt of either petroleum or natural base.