After reading this article you will learn about the suitable location and layout of a store.

Location of a Store:

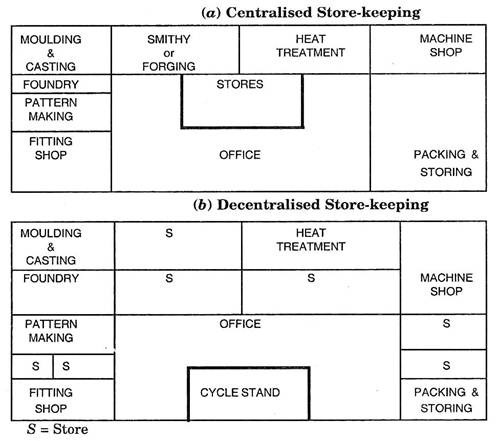

(a) Centralised Store:

In small factories, it is desirable to centralise the materials so that they may be brought under the control of one store-keeper and the store-room should be as far as possible near the place, where material is to be used.

If there are several manufacturing departments, the store-room will be most conveniently situated, where it is near to all departments. This will reduce handling and a lot of manual work is eliminated. This type is called Centralised Store.

(b) Decentralised Store:

In large factories, where there are several departments, each using different type of materials, it becomes beneficial to separate the stores.

For example, near the welding department, store the materials required for welding; near the foundry department, store the items which are used there; near assembly department, store the parts that are required there and so on.

Some stores that are common to several or all departments, as for example, soap, stationary, printed forms, cotton waste etc., should be kept at a central place.

This type is known as Decentralised Store.

Examples of both the types are shown with the help of sketches below:

Location of Materials:

In small factories, where there is one small store, the Store-keeper may remember the location of materials but in large factory where several thousand items are handled by him, memory would become unreliable.

Hence to facilitate the work of Store-keeper, it is necessary to set up a system of numbering the locations. Under this system, all locations in a Store-room are numbered and these numbers are entered in the Index register against the items which are located there.

Suppose code number for any item is 28-18 E-35. This means, the location is in store room 28, Rack 18, Shelf E and Bin 35. By this system, man approaches at the correct place for correct material, and issuing becomes quick and easy.

Layout of Stores:

It depends on the following factors:

1. Flow of Materials:

According to this factor, materials should move minimum possible distances.

2. Character of Materials:

The materials that are not damaged by weather can be stored outside in shed.

Materials like cement, plaster etc., must be placed in dry place. Tools and machines etc., should also be placed in dry places and coated to prevent rusting.

3. Quantity, Weight etc. of Materials:

It is necessary to find the space required for different purposes.

4. Frequency of Handling:

Handling consists of the following four stages:

(a) Receipts,

(b) Inspection,

(c) Storage and

(d) Issue of materials.

The following are general hints to carry out these stages of handling smoothly and correctly:

1. Layout is such that material may be quickly received in stores.

2. Unloading platforms are built of suitable height.

3. All around the stores there is thorough siding. If trucks are used for transporting the materials, sufficient parking space is provided.

4. For heavy material, suitable equipment for internal transport is provided.

5. It is to be seen that each section of the store has sufficient allotting space. The material is to be arranged in such a way that inward and outward movement of supplies can be carried out smoothly.