This article throws light upon the top nine techniques of scientific management introduced by Taylor in order to improve work efficiency and organisational productivity. Some of the techniques are: 1. Separation of Planning and Doing 2. Functional Foremanship 3. Job Analysis 4. Standardisation of Work 5. Financial Incentives 6. Differential Rate System 7. Scientific Selection and Training and Others.

Technique # 1. Separation of Planning and Doing:

Before scientific management principles were introduced, workers used to plan their work and worked under supervisors. Planning and also doing by workers themselves, though under the supervision created problems in productivity. Taylor advocated separation of planning from doing. Planning should be the task of supervisor and workers should only perform the work.

Technique # 2. Functional Foremanship:

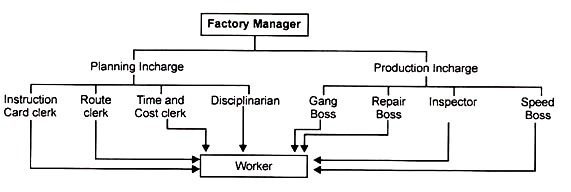

He introduced the concept of functional foremanship which violated the principle of unity of command. As planning was separated from doing, Taylor advocated that activities of workers should be supervised by two sets of supervisors based on specialisation of functions as one supervisor cannot supervise all aspects of the work (functional foremanship).

While one set of supervisors dealt with planning function to direct the activities of workers, the other set of supervisors dealt with the doing function. Both the Planning and Doing (Production) in-charges had four supervisions each resulting in eight supervisors who supervised the workers.

These supervisors are as follows:

I. Supervisors concerned with planning of work in the factory office (Planning In-charge):

(i) Route clerk:

He specifies the route that workers should follow in performing the task, that is, how work moves from one machine to the other and in what sequence (or route) to complete the task.

(ii) Instruction card clerk:

Various instructions for completion of the task like, which tools and equipment’s are to be used, at what speed the work has to be performed and other technical details are given by the instructions card clerk.

(iii) Time and cost clerk:

He specifies the time in which workers should perform the various work activities and also determines the cost at which work should be performed.

(iv) Disciplinarian:

He ensures discipline in the organisation by observing that workers work according to factory rules and regulations. Cases of absenteeism, insubordination, violation of rules etc. are dealt according to rules by the disciplinarian.

II. Supervisors concerned with execution of work at the shop floor (Production In-charge):

This set of supervisors has the following four supervisors:

(i) Gang boss:

He performs the preliminary operations regarding how workers should work on the machine. He also decides about which physical resources (tools and equipment’s) are required at the work place and arranges for them.

(ii) Speed boss:

He ensures that work is done in time. The speed at which various operations are performed should be in accordance with the standards laid for time taken to complete the task.

(iii) Repair boss:

He ensures security and maintenance of the machines on which work is performed. Workers should keep the machines in perfect order by taking proper care and perform maintenance activities like regular oiling, check ups and repairs.

(iv) Inspector:

He ensures that work is done according to the standards laid by the planning in-charge.

Functional foremanship, a technique of scientific management can be represented as follows:

Technique # 3. Job Analysis:

It involves analysing the job on the basis of following parameters:

(i) Time study:

It analyses the job by breaking it into different elements and determines the time taken to complete each element of the job. In order to increase productivity, optimum time to perform each operation is determined. The optimum time is the minimum time taken to perform the task. It helps in determining the ‘fair day’s work’ that each worker can perform in a specific time period.

It divides the work into smaller units or operations, observes the time taken to perform each operation (difference between the finishing time and starting time) by an average worker (after making adjustments for rest time while performing the operation), arrives at standard time on the basis of performance of average worker and determines that standard time as time required to perform the operation of work.

Similar exercise is carried for other operations and standard time is found for completing the whole work. Time study helps in determining the fair day’s work, that is, given the number of working hours in a day, how many units can be produced per worker per day.

(ii) Motion study:

It analyses the job by breaking it into various movements, identifies the essential movements and eliminates the unnecessary or wasteful movements. When only necessary movements are performed in doing the job, work is done in lesser time and reduces the fatigue of workers.

Motion study helps to find out the best way of doing the work. It studies the motions that a worker carries out while performing a job, eliminates unnecessary or wasteful motions that result in fatigue and extra time to perform the work, arrives at the best combination of motions or the minimum time required to perform the work to improve efficiency and determines that as the standard motion for performing the given task.

The time and motion studies together determine what is fair day’s work and what is the best way of performing it.

Time study studies the time taken to perform each operation of the task, motion study studies the motion of workers to perform that operation.

Time study eliminates wasteful time in performing an operation and motion study eliminates wasteful motions in performing the same.

Time study determines the fair day’s work and motion study determines the best way of doing that work.

(iii) Fatigue study:

In order to increase the capacity to work to their maximum potential, workers require rest between the work activities. The amount of rest and the frequency of rest intervals helps in removing the fatigue and enhances their work potential.

Rest periods help them regain energy and bring change in the quality of performance. This increases productivity and profits.

According to Gilbreth, motion and fatigue are directly related. Elimination of unnecessary motions from the work eliminate some amount of fatigue also. This increases efficiency of the worker and contributes to his and the organisational welfare in terms of productivity, profits and wages.

(iv) Method study:

Method study determines the best method of doing the work through optimum utilisation of human and non-human resources. It determines the specifications and technological feasibility of the products and designs an operation system that is optimum in terms of product design, job and process design, capital equipment selection, location of facilities, layout of facilities etc. It results in optimum utilisation of production facilities, reduces the materials, reduces transportation, storage costs and handling costs and results in low cost per unit of output.

Technique # 4. Standardisation of Work:

In order to ensure uniformity in work operations, work should be standardised. It ensures that everyone works according to same standards framed in respect of time, cost, amount of work, working conditions, quality of work etc.

Standard is “a unit of measurement established to serve as a criterion or level of reference for performance.” Standardisation is the process of setting standards for products, tools, equipment’s, work methods etc. Standards are set after scientifically observing and analysing the present performance, assessing the past performance and judging the capacity of employees to achieve those standards. Standardisation determines similar methods and techniques for production and maximises efficiency with which work is performed.

Technique # 5. Financial Incentives:

Workers have dominant financial needs and put in hard efforts if they are rewarded with financial incentives. Taylor advocated that reward system should be related to individual performance and not position of a person at the job. Thus, incentives can be provided by relating remuneration with productivity.

Technique # 6. Differential Rate System:

Taylor introduced ‘differential rate system’ where higher wage rate was paid to workers who finished the work in less than standard time (standard time was determined on the basis of time study) i.e., higher wage to productive workers and lower rate to those who produced less than the standard output. In fact, those getting less could also look for alternative jobs as labour supply was scarce at that time.

This system of incentive increased the wages by 30 to 100%.

For example, if workers are paid 0 per unit if they produce less than or equal to the standard output (100 units) and Rs. 11 if they produce more than the standard output, wages of A (who produced 100 units) and B (who produced 120 units) would be as follows:

A: 100 x Rs.10 = Rs.1,000

B: 120 x Rs.11 =Rs.1,320

Thus, A would be motivated to produce more to earn more and B would be motivated to maintain his production to earn more. This increases organisational productivity.

Technique # 7. Scientific Selection and Training:

Scientific selection involves selecting the right person for the right job. Workers should be selected on the basis of knowledge, ability and experience and placed at the most appropriate job for which they are suited. Training enhances their skills to make them more effective and productive on the job.

It develops workers by imparting them formal education, training (through time and motion studies) and motivation to enable them to perform at maximum efficiency. Workers will perform at their best, thus, maximising organisational output and job satisfaction.

Technique # 8. Task Planning:

Task refers to the work to be performed. It transforms organisational plans into reality. It is a series of operations which have to be performed scientifically to maximise the efficiency of task. Scientific task is the task that an average worker can perform in a day.

Task planning refers to setting standards of performance in terms of task features such as skill variety (skills required to perform a task), task identity (whether a product is produced in whole or in parts) task significance (importance of task for people working within and outside the organisation), autonomy (the extent to which task can be performed by the individual alone) and feedback (information about how successfully the task has been accomplished).

Scientific task planning involves the following five functions:

(i) Routing:

It determines:

(1) The operations,

(2) The sequence of operations, and

(3) The path through which the operations will be performed.

(ii) Loading:

It refers to assigning the work to a machine in advance so that best machine can be selected to optimise the production and control decisions.

(iii) Scheduling:

It enables different operations to be finished on time so that subsequent operations do not suffer and the goods can be delivered in time. Scheduling determines the time at which each operation is to take place.

(iv) Dispatching:

It involves issuing orders by the head operations department to start the operations.

(v) Expediting:

This is similar to controlling function. It ensures that production activities are carried according to the plans.

Technique # 9. Shorter Hours, Rest Pauses:

Long working hours without rest periods is tiring. Workers report low performance if they work continuously without rest periods. Taylor introduced shorter hours and rest pauses during work to increase the efficiency in terms of quantity and quality. The above techniques of scientific management aimed at improving organisational productivity and rewarding workers for increasing their individual productivity.