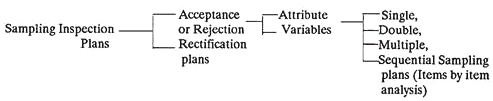

Sampling plans may be classified as follows: 1. Single Sampling Plans 2. Double Sampling Plans 3. Multiple Sampling Plans 4. Sequential Sampling Plan (Item by Item Analysis).

1. Single Sampling Plans:

A lot is accepted or rejected on the basis of a single sample drawn from that lot.

i. Under this plan, a lot is accepted or rejected on the basis of a single sample drawn from that lot.

ADVERTISEMENTS:

ii. Method.

1. Draw a single sample of size n i.e., of n component parts. The sample size may either be

i. calculated, or

ii. found from tables.

ADVERTISEMENTS:

2. Inspect the sample and find the number of defective components.

3. If defective pieces exceed the acceptance number C, the lot is rejected and vice versa.

4. In case the lot is rejected, inspect each and every piece of the lot and replace the defective parts or salvage and correct the defective parts.

Calculation of sample size

ADVERTISEMENTS:

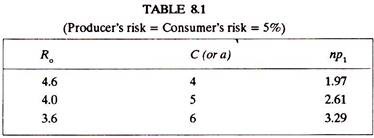

Given AQL or P1 = 2%

LTPD = 9.2%

... Operating ratio, Ro = LTPD/AQL (or P1) = 9.2/2 = 4.6

From Table 8.1 for Ro = 4.6: Acceptance number C = 4 and np1 = 1.97

Thus sample size = np1/p1 = 1.97/2% = 99.

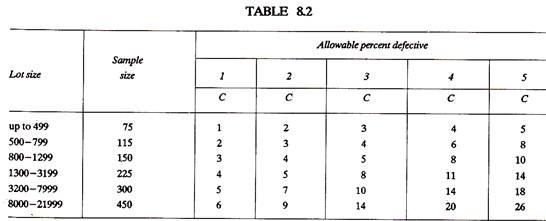

Determination of sample size from the table (8.2)

For a lot size of 850 and allowable percent defective 3%.

ADVERTISEMENTS:

Table 8.2 gives a sample size of 150 and acceptance number, c as 5.

This means from the lot containing 850 parts, at random pick up 150 parts, inspect them and find out the number of defective pieces. If defective pieces are up to 5, accept the lot; if their number is 6, 7, 8 or more, reject the lot.

Characteristics of Single Sampling Plan:

(i) A single sampling plan is easy to design, explain and administer.

ADVERTISEMENTS:

(ii) It is the only practical type of sampling plan under conveyorized production conditions when only one sample can be selected.

(iii) It involves a lower cost of training and supervising employees, transporting and sorting samples, etc.

(iv) It very accurately estimates lot quality.

(v) It is more economical than double sampling plan when lots have their % defectives close to the AQL.

ADVERTISEMENTS:

(vi) It involves a bigger sample size than the double sampling plan.

(vii) It involves record keeping less than that of double and multiple sampling plans.

(viii) A single sampling plan provides maximum information concerning the lot quality because each sample can be plotted on the control chart.

2. Double Sampling Plans:

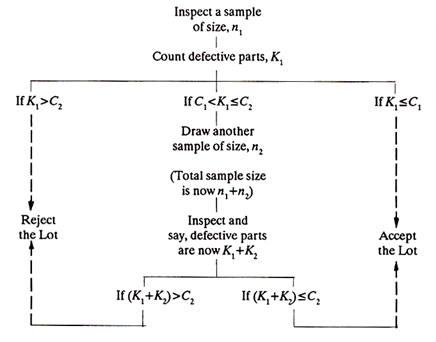

If it is not possible to decide the fate of the lot on the basis of first sample, a second sample is drawn and the decision is taken on the basis of the combined results of first and second sample.

1. If it is not possible to decide the fate of the lot on the basis of the first sample, a second sample, is drawn out of the same lot and the decision whether to accept or reject the lot is taken on the basis of the combined results of first and second samples.

2. Double sampling plan procedure

ADVERTISEMENTS:

Given C1, and C2 as acceptance numbers; C2 > C1,

Characteristics of double sampling plan:

(i) A double sampling plan is more expensive to administer than a comparable single sampling plan.

(ii)It involves less inspection than that required for a single sampling plan.

(iii) Double sampling plan is easier to sell to the personnel because psychologically the idea of giving a second chance to a lot before rejecting it exercises popular appeal.

ADVERTISEMENTS:

(iv) It permits a smaller first sample than the sample size of the corresponding single sampling plan.

(v) A double sampling plan involves more overheads than a single sampling plan.

(vi) It involves more record keeping than a single sampling plan.

3. Multiple Sampling Plans:

A lot is accepted or rejected based upon the results obtained from several samples (of parts) drawn from the lot.

i. A multiple sampling plan accepts or rejects a lot upon the results obtained from several samples (of component parts drawn from a lot).

ii. Multiple sampling plan procedure.

Characteristics of multiple sampling plan:

(i) A multiple sampling plan involves smaller first samples than single or double sampling plans.

(ii) A multiple sampling plan is comparatively difficult to design and explain, and expensive to administer.

(iii) It involves a higher overhead cost as compared to single and double sampling plans.

(iv) It involves more record keeping.

(v) In theory, multiple sampling may often permit lower total inspection than double sampling for a given degree of protection because of smaller sample sizes required.

ADVERTISEMENTS:

(vi) New methods, which simplify multiple sampling, such as automatic sampling boxes may result in greatly improved efficiency in administering multiple sampling plans.

4. Sequential Sampling Plan (Item by Item Analysis):

Sequential sampling involves increasing the sample size by one part at a time till the sample becomes large enough and contains sufficient number of defectives to decide intelligently whether to accept or reject the lot.

It is a plan in which sample size is increased by one piece (or part) at a time till the sample becomes large enough and contains sufficient number of defective pieces to decide intelligently whether to accept the lot or to reject it.

It is easy to design, but more expensive to administer than a comparable multisampling plan, since more steps are needed to take a decision. Since sample size is increased by one at a time, sample results are analysed much faster than in a single or double sampling plan. Sampling costs are least. Overhead cost is maximum. It is seldom used in lot acceptance control but is important because multiple sampling is based on it.