After reading this article you will learn about the design considerations for work place layout.

(1) Materials and tools should be available at their predetermined places and close to the worker.

(2) Tools and materials should preferably be located in the order in which they will be used.

(3) Wherever possible gravity should be employed for, the raw material to reach the Operator, and finished product to be delivered at its destination. However, it should not be too automatic to become monotonous and boring for the operator. Under such conditions suitable breaks and rest periods should be provided.

(4) The opera tor should have comfortable posture. The height of his seat should position the worker such that the work table is about 50 mm below the elbow level of the operator.

(5) A worker should have his choice to sit or stand freely during work; that means it should be possible to work both while sitting or standing. A flat foot rest should be provided for the Sitting Workers.

Sitting is less tiring as compared to standing. Seat should not be very long and may have an angle of four degrees. The back of the seat should not restrict the arm movements (essential) during work.

(6) Worker should be able to operate levers and handles without changing body position.

(7) The work place should have enough illumination, proper conditions of heat, cold and humidity, and reduced dust, noise, etc.

Suggested Work Place Layout:

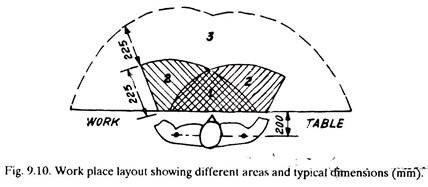

Figure 9.10 shows a work place layout with different areas and typical dimensions.

1. Actual Working Area:

It is most convenient area for working.

2. Normal Working Area:

It is within the easy reach of the operator.

3. Maximum Working Area:

It is accessible with full arm stretch.

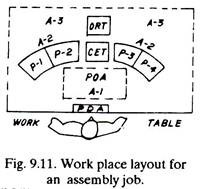

Figure. 9.11 shows work place layout for assembling small component parts. A-1 is the actual working area and the place of assembly (POA) where four component parts P-1, P-2, P-3 and P-4 are assembled together. Bins containing P-1, P-2, P-3, P-4 and commonly employed tools (CET) (like screw driver, plier, etc.) lie in the normal working area A-2. Occasionally required tools (ORT) (hammers, etc.) lie in the maximum working area A- 3. After the assembly has been made at POA, it is dropped into the cut portion in the work table-PDA (place for dropping assemblies)-from where the assembly is delivered at its destination with the help of a conveyor.

This work place arrangement satisfies most of the principles of motion economy.