After reading this article you will learn about the steps and equipments of stop watch procedure for collecting time study data.

Procedural Steps:

The various steps involved are as follows:

1. Establish the quality to be achieved in the product. Strike a balance between a low and very high quality. Low quality means more rejection and scrap and very high quality marks uneconomical production.

2. Identify the operations to be timed.

3. Obtain the improved procedure from the method study department.

4. Collect the necessary equipment and ensure their accuracy.

5. Select the worker to be observed.

6. Take the worker as well as supervisor into confidence and explain to them the objectives of the project.

7. Explain to the worker the improved working procedure and the use of tools, jigs, fixtures and other attachments.

8. Break the operation into small elements and write them on the proper form.

An element may be defined as a distinct part of an operation or working procedure. The element, being a small entity makes it convenient to be observed, measured and analysed.

The different objectives of element breakdown are as follows:

(i) To separate productive and unproductive activities or effective and idle times,

(ii) To get complete and accurate information,

(iii) To access accurately operator’s performance,

(iv) To produce detailed work specification,

(v) To select the best method by comparing the work elements of two or more given methods, and

(vi) To collect information to compile standard data.

9. Separate constant (time) elements from variable (time) elements. (Machine elements and manual elements are the examples of constant time and variable time elements)

10. Determine the number of observations to be timed for each element.

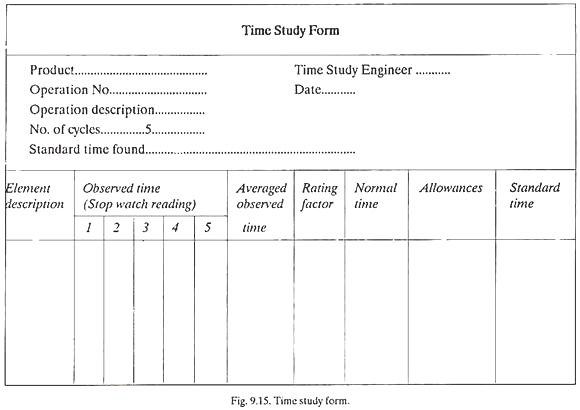

11. Conduct the observations (of timing the elements) and record them on the time study form (Fig. 9.15).

Measurement of time can be done by any one of the three, i.e., non-fly back, fly back or split hand techniques. In continuous timing method a non-fly back type of stop watch is employed. It is started as the first element begins and the reading is taken as the first element ends and the second element begins. Stop watch hands move continuously and the reading is noted again as second element ends and third begins and so on.

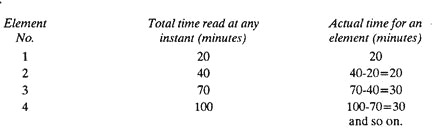

At the end of the specified number of elements, the time for each element is found as follows:

12. Rate also the performance of the worker during step (11).

13. Repeat steps (11) and (12) for taking more than one observations.

14. Compute observed time from the measure of central tendency.

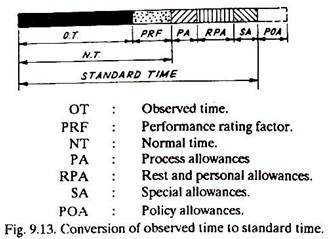

15. Calculate normal time from observed time by using performance rating factor.

16. Add process allowance, rest and personal allowances, and special allowances to the normal time in order to obtain Standard lime or Allowed time. Policy allowances are in addition to standard time. (Fig. 9.13).

Standard Time may be defined as the amount of time required to complete a unit of work:

(a) Under existing working conditions,

(b) Using the specified method and machinery,

(c) By an operator, able to the work in a proper manner, and

(d) At a standard pace.

Stop watch study is employed:

(a) For checking time standards obtained by other methods;

(b) For timing repetitive operations employed in manufacturing different jobs;

(c) Where it becomes necessary to break down an activity (involving motions of head, leg, foot, trunk, etc.) in detail and study.

Stop Watch Time Study Equipment:

Stop watch is one of the principle timing devices employed for measuring the time taken by an operator to complete the job. Besides stop watch, motion picture cameras and time recording machines have also been used.

Stop watch is an accurate time measuring equipment (watch) which can run continuously for one hour or half an hour normally and records time by its small hand. One revolution of the big hand of the watch (Fig. 9.14) records one minute and the scale covering one minute may be calibrated in intervals of 1/300th of a minute or 1/100th of a minute.

A stop watch may be of the following types:

1. Non-fly back,

2. Fly back, and

3. Split hand or split second type.

1. Non-Fly Back:

Non-fly back stop watch is preferred for continuous timing. First pressing of the winding knob starts the watch and long hand begins moving. If winding knob is pressed second time, the long hand stops and with third pressing, hands return to zero position.

If two elements are to be timed and the second element is immediately after the first, the non-fly back system does not work well because it involves stopping the watch at the end of first element, pressing the knob to bring hands back to zero, and again pressing the knob to start the hands; which consume quite some time and hence the second element cannot be timed accurately. Such cases require the use of fly back or split hand type of watch.

2. Fly Back:

In fly back system, the watch is started and stopped with the help of the slide (Fig. 9.14). Pressing the winding knob brings the hands back to zero, but they do not stop, start immediately moving forward again. To stop the hands at any point, slide is used. This stop watch is preferred for taking fly back (or snap back) timing or continuous timing observations.

3. Split Hand or Split Second Type:

Split hand type of watch gives greater accuracy in reading when two elements are to be timed and one immediately follows the other. As one element finishes, pressing the winding knob makes one hand to stop (so that an observer can read time accurately) while the other keeps moving. After the reading has been taken, a second pressing on the knob restarts the (stopped) hand and the two hands go together.

Besides a stop watch, the other equipment needed for time study are, time study form (Fig. 9.15), time study board, steel rule or measuring tape, tachometer, micrometer, pencil, slide rule or calculator, etc.