This article provides notes on Work Study. After reading these notes you will learn about:- 1. Meaning of Work Study 2. Productivity and Work Study 3. Work Study Department 4. Quality of Work Study Man 5. Good Relations for Work Study 6. Applications 7. Work Study and the Management.

Meaning of Work Study:

Work study is a technique which deals with the problems:

(i) As to how should a job be done and

(ii) How much time a job should take for completion?

Answer for the question, as to how a job should be done, is found by Motion Study (commonly known as Method Study) or sometimes termed as “Work Simplification”. Answer for the second question is found by the Time Study (now-a-days termed as “Work Measurement”).

Object of Work Study is to determine the best method of performing each operation and to eliminate wastage so that production increases with less fatigue. The work study is also used in determining the standard time that a qualified worker should take to perform the operation when working at a normal pace.

According to the British Standard Institution, “Work Study” is a general term for those techniques, particularly method study and work measurement, which are used in its context, and which lead systematically to the investigation of all the factors, which affect the efficiency and economy and the situation being reviewed in order to effect improvement.

Work study was earlier recognized as “Time and Motion Study”. According to Taylor, there was a great difference in these two terms. Work study has a broader concept while time and motion study was mainly used for determining time standards and motion economy.

Work study is the analysis of work into small parts followed by rearrangement of these parts to give the same effectiveness at a lesser cost. It examines both the method and duration of work involved in a process.

Thus, work study is the analytic investigation of the methods, conditions and effectiveness of industrial work, and thereby determination of the ways in which human efforts be applied economically.

Therefore, work study is one of the most important management techniques, which is employed to improve the activities in the production. It assists the management in the optimum use of human and material resources.

Work study has following three aspects:

(a) More effective use of plant and equipment.

(6) More effective use of human efforts.

(c) Evaluation of human work.

Productivity and Work Study:

As we know that, productivity is nothing but the reduction in wastage of resources. The resources may be men, machines, material, power, space, time etc.

We have also seen from the definition of work study, that it reduces wastage of time, effort, and increases the efficiency of man and machine. Thus the work study techniques lead to increase the productivity.

According to V.K.R. Menon, productivity implies development of an attitude of mind and constant urge to find better, cheaper, easier, quicker and safer means of doing a job, manufacturing a product and providing service.

But we see that most of these objects can be achieved by different activities of work study. To improve the economic position of our country in comparison to other countries, we must improve our productivity and performance.

In recent years, there had been regular pay increases, but we have forgotten that without improving the productivity, prices will be sky rocketing and we will lose competition in the world market. To compensate for wage increase, we must increase the productivity.

To fight against inflation, we must increase the productivity. The battle fields of this fight are every place where resources (men, material, equipment, money, time, efforts etc.) are involved.

The factory and the agriculture are most important places where we must emphasize for productivity improvement. Other places like offices, hospitals, teaching institutions etc. also need productivity improvement, if the society and the country is to move forward.

Thus our aim must be to make people more productivity conscious, if we want to improve their standard of living. Productivity holds the key to the prosperity of the individual, a company and a nation.

Increase in productivity results in:

(1) Increase in production and hence higher profits.

(2) Products produced will be cheaper.

(3) Higher wages and bonus can be allowed to workers because of large profits.

(4) Improvement in living standard of workers.

(5) Brings prosperity in the country.

“Work Study is an organised continued efforts to improve productivity and quality, and to reduce costs within an organisation”. For this purpose a work study engineer must continue to lead the way in “Resources Utilisation”.

Following are the lines of attack to improve the productivity:

1. Improve the basic process.

2. Provide more and improved physical means to motivate the workers.

3. Simplify and improve the product and reduce the variety.

4. Improve the methods of operation.

5. Improve organization, production planning and control,

6. Improve manpower efficiency at all levels.

Work Study Department:

Work Study Department must be given a high position in a factory, so that the persons working in the department cannot be influenced by the officers working on the floor and their suggestions can be accepted with respect and acted upon.

Work Study Department generally works as a part of the Industrial Engineering Department. Since the Industrial Engineering Department is for the service of the management of an enterprise, therefore, it must be a staff and not a line activity.

The position of the head of the Industrial Engineering Department in relation to his fellow members of the staff depends upon following important factors:

(i) Size of the organisation.

(ii) Type of organisation and whether managed by owner himself or by professionals.

(iii) Nature of work carried out in the factory.

(iv) Qualifications, experience personality etc. of the Chief Industrial Engineer and those of other departmental heads.

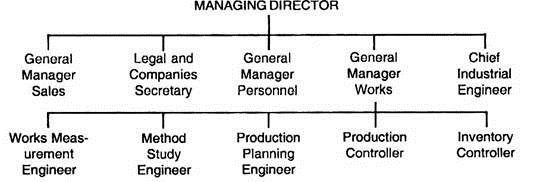

Looking to above factors, there cannot be any standard chart for organisational structure. A typical organisation chart showing the position of Industrial Engineering Department is given as under.

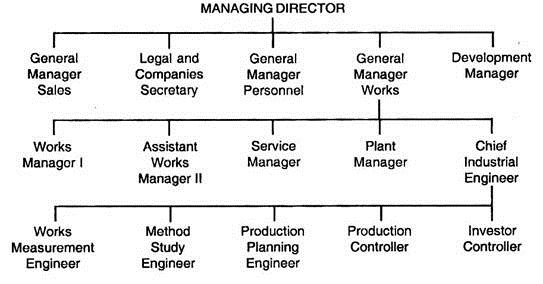

Sometimes Chief Industrial Engineer is given a place under General Manager Works. It is due to the reason that he is responsible to increase the overall productivity and by putting the Industrial Engineering Department under him, he can give more importance to the suggestions or advices placed before him.

In such case, the organisational structure will be similar to that shown in the chart below:

Quality of Work Study Man:

Certain qualities are expected from a work study man, however they vary from work to work. Here some of the required qualities are explained.

(A) Qualifications Abilities:

(i) Good knowledge of work study techniques.

(ii) Good knowledge of different manufacturing process for which he is conducting the work study.

(iii) He must be well qualified and sufficiently trained.

(B) Mental Abilities:

(i) Mentally prepared and interested to do that work.

(ii) Good observation power, i.e. mental alertness, quick to notice.

(iii) A man of clear thoughts.

(iv) Power to express things clearly.

(C) Personal Qualities:

(i) Sincere and honest, so as to gain the confidence and respect of those with whom he had to deal.

(ii) He must have enthusiasm.

(iii) Tactful in handling the situation.

(iv) Self-confidence, strong will power and courage.

(v) Leadership capabilities.

Good Relations for Work Study:

One of the greatest difficulties in obtaining the active cooperation of the workers is the fear that increasing the productivity will lead to their unemployment. Therefore, before introducing the work study, relations between the management and the workers must be reasonably good and the workers must have confidence in the sincerity of the management towards them. In the absence of good relations, workers will consider it as a trick to get more work out of them without giving any benefit.

The second main difficulty is that, due to the general conservatism of human beings, any change in existing methods and practices is an interruption of a comfortable situation in which well-established routines have been set up.

The third important difficulty is that, when a work study team work in a plant, it appears that it has taken up management’s role. The sitting managers do not like it and feel that their positions have been illegally seized.

Therefore, it is necessary to know how the good relations with the workers on one side and with the management on the other side can be maintained.

Application of Work Study:

If the workers have confidence in the sincerity of the management then there will be no difficulty in the application of work study. Before conducting the work study all the problems must be discussed honestly.

Before and during the course of application of work study following steps are advisable:

1. Management must take initiative for free and sufficient consultation before the work study is started.

2. If work study is applied, then workers and their representatives are kept fully informed of all that is being done. All the record of work study must also be made available for them to develop a feeling of confidence.

3. Work study improves the flow of work and supply of material. This improves the efficiency of the workers and thereby their earnings. This aspect is liked by the workers very much, specially if they are on piece work.

4. Generally there is a fear of redundancy arising out of the results of work study. There must be definite policy in respect of their retrenchment or transfer to another department. This is a very important factor and must be discussed by the management and the unions.

5. There may be strong resistance to changes in method of work as a result of method study. The workers must be explained about the new method and its advantages. Sometimes old skilled workers are not satisfied even after this, then as a solution of it, if the output of these old workers is reasonably satisfactory, they will have to be left alone and the changes are taught to the new workers only.

6. Sometimes workers hesitate in being timed, because somebody standing nearby and watching worries them, in such cases position of work study man must be such that so as to disturb the worker as least as possible. Work study man must also see that before attempting to record times, worker becomes accustomed to his presence.

7. Workers representatives should be trained in the techniques of increasing the productivity. This will help in understanding them about the importance of work study and they will also be able to explain it to their fellow workers. This will also help them in ensuring that no steps are being taken which may harm to them.

Work Study and the Management:

Two types of difficulties are generally experienced from the management side. Firstly, as a psychology of human beings, any change in the existing method is an interruption of a comfortable situation in which routines have been set up.

Secondly main difficulty is that when work study experts are active in the plant, sitting managers may feel that their role of management has been taken up by the work study experts and their position has been illegally seized.

Sometimes supervisory staff like Foreman etc. do not co-operate with these experts which will result that workers also not care for these specialists and do not make any efforts to carry out their suggestions.

This difficulty do not occur at all, if all concerned are clear that the Work Study Department is like a tool of the management for helping to improve the productivity.

Work Study man must observe following rules so as to overcome these difficulties:

1. Work study man must not give orders to the workers directly.

2. They must not discuss any matter with the workers which are outside the jurisdiction of work study. If such questions are asked by the workers, they must be referred to their Foreman.

3. The work study man must also seek help from the Foreman regarding managerial matters.

4. At the start of the work, study man must seek the introduction of the workers through the Foreman.