After reading this article you will learn about:- 1. Meaning of Critical Path Method (C.P.M.) 2. Language of Critical Path Method 3. Advantages.

Meaning of Critical Path Method (C.P.M.):

The use of this management technique of modern network systems has become very essential in the developing countries like India. This was developed in 1957 and is suitable for the construction of projects and for scheduling plant maintenance etc. C.P.M. technique is useful to determine how best to reduce the time required to perform routine production, maintenance and construction and to minimise the direct and indirect expenses. C.P.M. was first used by the research team led by Morgan R. Walker to determine how best to reduce the time required to perform routine plant overhauling, maintenance and construction work.

With the help of C.P.M., a manager can know that which operation should be started after completing a particular operation and what is the status of the work as related to the scheduled timings?

Although, an experienced person knows it but this information, available from the network helps all concerned. It also tells that at what moment, and in which operation time schedules are adhered strictly so that future programme is not affected, and where it can be delayed and to what extent without affecting the last date of completion of project.

Language of C.P.M Network:

The C.P.M. technique has its own language, which can be understood only when following terms and their representation is known.

These terms are being described here:

(i) Operation or Activity:

A Project consists of several activities or operations and the project is known to be completed when all such activities are completed. In AON system, operations are represented by the circles.

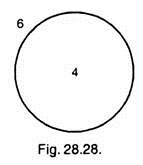

Different operations are numbered and these numbers are posted inside the circles representing that operation. The schedule time is written on the left top corner of the circle. Fig. 28.28 shows that the operation number 4 has its schedule time of 6 days.

(ii) Pre-operation:

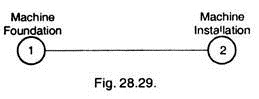

Pre-operations (PRE-OPR) are the operations which precede the operation under consideration, e.g., machine installation can only be done after machine foundation is completed, and thus machine foundation is the pre-operation of machine installation and is written on the left as shown in Fig. 28.29.

The arrow connecting these two circles shows the relation between them and indicates that the operation on the left end of the arrow should be completed before the beginning of the operation on the right end of the arrow.

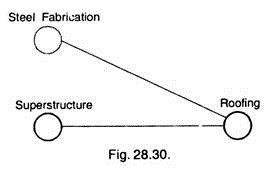

Sometimes an operation has more than one pre-operation e.g., roofing of a workshop can only be started when super structure and the steel fabrication is completed. Thus ‘steel fabrication’ and super-structure are the “Pre-operation” of the roofing as shown in Fig. 28.30.

(iii) Post-operations:

Post-operations (POST-OPR) are the operations which follow after the operation under consideration is completed. In the previous example of Fig. 28.29, ‘Machine Installation’s is the POST-OPR’ of the machine foundation’. In the example shown in Fig. 28.30, ‘roofing’ is the POST-OPR’ of ‘Steel fabrication’ and ‘super-structure’.

(iv) Concurrent Operations:

These are the independent operations and do not have any ‘PRE-OPR’ and these can be started separately at the same time. In Fig. 28.30, Steel fabrication and superstructure are the concurrent operations.

(v) Earliest Finish:

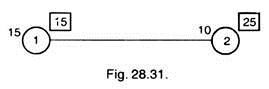

It is the earliest possible time in which the particular operation can be completed. This is given on the top right corner outside the operation circle and is enclosed in a rectangle.

It will be clear from the example shown in Fig. 28.31 in which machine foundation has its schedule time of 15 days and it does not have any PRE-OPR, hence its ‘earliest finish’ is 15 days. Operation ‘Machine installation’ has 10 days schedule time and its PRE-OPR will take 15 days, thus the ‘earliest finish’ of this is 15 + 10 = 25 days i.e., this operation can be completed after 25 days of starting of the work.

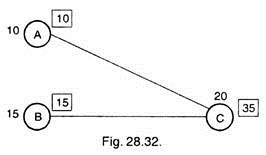

When any operation has more than one PRE-OPR than earliest finish time = Largest of the earliest finish of PRE-OPRS + schedule time for the operation under consideration. In the example shown in Fig. 28.32, earliest finish time for operations A and B are 10 and 15 days respectively (as they have no PRE- OPRS, their earliest finish = schedule time) and the earliest finish for C.

= Largest of the earliest finish of PRE-OPRS plus schedule time for operation C.

= 15 + 20 = 35 days.

(... 15 is the largest earliest finish among operations A and B)

(vi) Latest Finish Time:

It is the latest time by which the operation must be completed so that scheduled date for the completion of the project may not be delayed.

For last operation: Latest finish = Earliest finish

For other operation: Latest finish = Latest finish of the post-operation-time required for post operation.

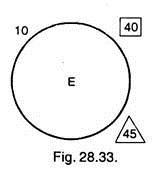

Note that if any operation has more than one post operations then use smallest among them. It is written in a triangle below the operation circle. Fig. 28.33 shows that operation time for E is 10 days and its earliest finish is 40 days while its latest finish time is 45 days.

(vii) Critical Path:

A path along the network in which ‘Earliest Finish’ and ‘Latest Finish’ are equal is known as ‘Critical Path’ and is represented by the double or thick arrow line to distinguish clearly. More stress is given on this path, because a slight delay on this path will effect adversely on the completion time of the whole project.

(viii) Slack:

It gives the range of time available at an event for accomplishing an activity without delaying the project completion date. On critical paths slack is zero. Slack is the difference between the latest finish time and the earliest finish time i.e. in the event shown in Fig. 28.33 slack is (45 – 40) = 5 days.

(ix) Earliest Start:

It is the earliest possible time by which the work can be started.

Earliest Start = Earliest finish time—Operation time.

(x) Latest Start:

It is the latest possible time by which the work can be started.

... Latest start = Latest finish time—Operation time

(xi) Positive Slack:

If TL – TE is positive, then this represents a situation where extra resources (men, material and machines) are available.

Negative Slack:

If TL – TE is negative, then this represents that the programme is falling behind schedule.

Zero Slack:

If TL – TE is zero then this represents an ideal situation which falls on the “Critical Path”.

Due to slack conditions, there may be more than one critical path. In such a case, all the paths should be analysed to evaluate the resulting actions by changing one or more events or activities along the path as a means of improving ‘the schedule’.

Advantages of Critical Path Method:

Some of the important advantages are summarised here:

1. It helps in ascertaining time schedules.

2. With its help, control of the management becomes easy.

3. It makes better and detailed planning possible.

4. It enourages discipline.

5. It provides a standard method for communicating project plans, schedules and cost performance.

6. It identifies most critical elements and thus more attention can be paid on these activities.

The CPM technique requires greater planning than required otherwise. Thus, this method increases the planning cost but this cost can easily be justified by concentrating attention on critical paths only and avoiding unnecessary expenses on the strict supervision over the whole programme.