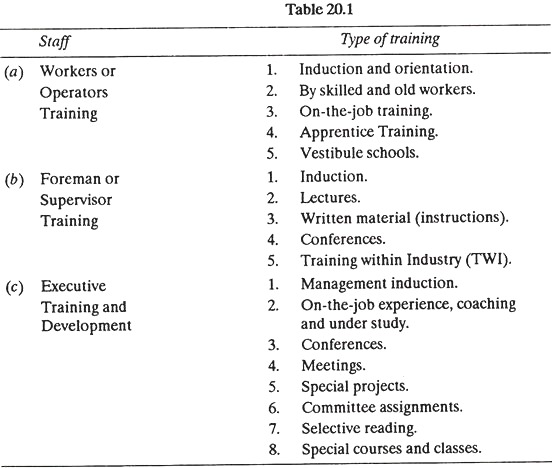

After reading this article you will learn about the forms of training conducted for different levels of staff: (A) Worker’s or Operator’s Training (B) Foreman or Supervisor’s Training (C) Executive Training and Development.

(A) Worker’s or Operator’s Training:

1. Induction and Orientation:

When a new worker joins a concern, everything is strange for him; physical layout is unfamiliar and he does not know to whom to approach for the most obvious day-today requirements. The induction and orientation training aims to get over this settling in period as quickly as possible and with the minimum of emotional upsets being experienced by the new employee.

Induction and orientation training involves familiarizing the new employee about the following:

(i) The concern or the enterprise which he has joined, its history, organisation structure, products being manufactured, etc.

(ii) Conditions of employment, disciplinary rules and other aspects of personnel policy.

(iii) Employee activities and service benefit plans.

(iv) Community facilities and plant facilities (e.g., Canteen, etc.)

(v) Information about the work, he has to undertake and the department in which he has to work.

(vi) Wage rate and incentive schemes.

(vii) Safety and proper use of tools and equipment.

(viii) Introduction with fellow workers and supervisor.

2. Training by Skilled, Experienced and Old Workers:

The new worker is attached with an old, skilled and experienced worker. The new worker watches the experienced worker while he works and then tries to do the same himself in the same way. From time to time he gets instructions from the skilled worker also.

This type of training can be seen in very small concerns, e.g., auto repair shops where there is no established training programme. This method of training has a disadvantage that the new worker will learn even the wrong work practices followed by the old worker.

3. On-the-Job Training:

On-the-job training is imparted to the new workers on-the job itself; no additional training equipment is required. This type of training is conducted either by the shop supervisor or by an experienced worker already familiar with the job.

The supervisor explains and demonstrates to the trainee the job, the use of tools and equipment and the correct procedure to do the job. The trainee is then asked to try himself and make the job. Mistakes, if any, made by the trainee are corrected and he is kept under constant watch until he develops correct work habits.

Advantages:

1. It is a simple and inexpensive method of training.

2. It does not require any additional machinery for training purposes.

3. Its flexibility permits a programme to be started and stopped at will and to be adjusted to the individual concerned.

4. The worker has first-hand experience with the job and learns by doing. He gets introduced very soon to the realism of the actual work situation.

Limitations:

1. All supervisors are not inherently successful teachers.

2. A trainee may not be able to learn efficiently on the production floor because of the noise and bustle of the work-place.

3. This type of training will not produce skilled workers in a short time.

4. On-the-job training does not produce workers uniformly skilled.

5. Working of trainee on the production floor may increase chances of spoilage of material, damage to equipment, accidents, etc.

6. On-the-job training tends to be administered and coordinated on a somewhat haphazard basis.

4. Apprentice Training:

Apprenticeship training has an academic side as well as practical one i,e, a trainee attends certain courses as well as receives practical training. Apprentice training is a variation of on-the-job training in which a trainee is taught the WHY as well as the HOW and he is given a broad training to enable him to take up a wide verity of tasks within his field of specialization. An apprentice is trained to do a job requiring highly skilled work applied to varying work patterns.

Under this scheme young boys 16 to 18 years of age are trained for 2 to 4 years. The training involves doing a planned sequence of jobs and spending a prescribed number of hours in the class-room. The apprentice is paid wages (normally increasing with the passage of time) for hours of instruction as well hours of production. Apprentice training is being conducted in a number of fields such as electrician, turner, welder, moulder, motor mechanic, etc. Apprentice training is a long, thorough and costly practice.

5. Vestibule Schools:

This type on training is performed outside the shop floor-as if it were carried out in the vestibule (i.e., a forecourt or an entrance hall) of the company before actual entry into the working part of the plant. It becomes necessary for a concern to start a vestibule training school when the amount of training to be imparted and the number of trainees exceed the capacity of a shop supervisor (to impart on-the-job training).

A vestibule school is set up on the company property and equipment actually used on the shop floor is duplicated as closely as possible. A large number of trainees undergo a planned course of instructions and practice usually by instructors not attached with immediate production. After the trainees achieve proficiency, they are transferred to production floor to take up regular production work without delay.

Advantages:

1. A large number of trainees can be trained in similar skills, quickly and uniformly.

2. Unlike on-the-job training, the vestibule school training does not damage actual production.

3. The school atmosphere is calm, peaceful and conducive to efficient learning.

4. Instructors are not worried about immediate production.

5. Specially trained and professional instructors can be employed for imparting instructions to trainees.

6. Wastage and spoilage of raw material and damage to production machinery is eliminated.

Limitations:

1. It is a costly affair and every industry cannot afford it.

2. Production machinery need be duplicated.

3. A trainee does not achieve familiarity with actual shop floor conditions while he is being trained in the vestibule school. Therefore he requires a period to adjust himself with the shop floor conditions when he enters the working area of the plant after completing his training in the school.

4. If the demand of workers is uneven, usually either a part of vestibule school is idle or trainees are rushed through it without proper training.

(B) Foreman or Supervisor’s Training:

Foremen or supervisors are the next step above the workers or operators level employees in the organizational pyramid. A foreman is the keyman who interprets management to the workers and at the same time is responsible for production. He stands between management and the rank and file level employees.

A supervisor generally has to take care of the following:

(i) Selecting and training of workers.

(ii) Work production.

(iii) Control of quality, quantity and cost.

(iv) Discipline, motivation and morale of workers.

(v) Work method improvement.

(vi) Accident prevention.

(vii) Maintaining machinery and supplies.

(viii) Compliance with labour laws.

(ix) Cooperation and coordination with other departments.

(x) Handling labour grievances.

(xi) Record keeping.

Therefore, the training of the foreman should be planned by keeping the above-mentioned points in view.

The foreman training should:

(i) Bring his impact up to the standard where he can handle his interactions with others effectively.

(ii) Primarily aim to develop the qualities of leadership.

(iii) Equip him with an adequate knowledge of management methods to deal with other people.

(iv) Broaden him and at the same time develop qualities of analysis that will enable him to visualize his job.

(v) Encourage the development of his motivation and adjustment.

(vi) Develop the foreman to qualify for advancement to positions of greater responsibility.

(vii) Impart to him a deep knowledge about the work so that workers should feel that he is superior to them.

(viii) Develop in him the skill to impart instructions to the workers under him.

(ix) Develop in him the skill to improve upon the existing methods of work.

(x) Preferably be conducted within the company itself.

Foreman Training Techniques:

1. Induction:

Any new employee whether he is a worker or foreman needs proper induction before he is asked to do the job or work pre-decided for him.

2. Lecture (class-room) method:

Class-room training depends entirely upon lectures as the medium of training. Lecture can be delivered to as many supervisors as can be accommodated in the room. Lecture is delivered by experts from within or outside the company. Lecture is a very good medium of training where no reliable books or other written material is available. The value of the lecture can be enhanced by using audio-visual aids such as technical films, slides, overhead transparencies, etc.

3. Conference:

A conference brings together many people who tend to train themselves and learn together. People attending a conference, compare, consider and discuss the subject matter of their interest, e.g., how to control absenteeism, how to minimize scrap rate etc. A conference helps pooling ideas and experiences of different persons and puts them open for discussions to arrive at a feasible solution of the problem in hand.

A conference can uproot fixed ideas, change attitudes and develop analytical and questioning ability. The conference discussions should be thoroughly planned and the points of conclusion (but not the conclusion itself) must be predetermined. The conference leader or trainer should guide, be active, lead, interpret, stimulate and draw out the ideas and opinions of the group engaged in discussion.

4. Training within industry (TWI):

An outcome of World War II was the TWI-Training within Industry Programme of the War Manpower Commission. This was basically a supervisory training programme to make up for the shortage of civilian supervisory skills during the war. One of the parts of this programme was the job instruction training course, which was concerned with how to teach. During war time and even afterwards more supervisors have been trained by TWI than by any other method.

TWI courses can be held on a concern’s premises and cause little disruption of work. TWI courses are based upon group conference method, and supervisors attend on a part-time basis. TWI courses can be easily adapted to special needs and impart effective training in minimum time.

A TWI course imparts training in:

(a) Job instruction:

The supervisor develops the ability to impart clear instructions to the workers as regards what to do and how to do it.

(b) Job relation:

This programme develops in a supervisor, leadership qualities, the ability to analyse and handle labour problems, the ability to promote good working relations.

(c) Job method:

This programme increases supervisor’s skill to improve methods of doing work, and make best use of men, materials and machines.

(d) Job safety:

Supervisor learns how to prevent accidents. Spot dangers and eliminate them.

(C) Executive Training and Development:

Executive training and development is one of the most important and complex tasks of Personnel Management. Larger concerns give increased attention to the training and development of their Managers and Executives. The primary emphasis in executive development should be in self-development. There is no substitute for personal drive, initiative and ability.

Executive training and development can be classified as follows:

(i) On-the-job training and development which includes:

b. Learning by experience.

c. On-the-Job coaching.

d. Understudies. The trainee is kept understudy and he learns the ways of his superior under whom he is at study.

e. Position Rotation. Rotating an executive from one position to another broadens his background in the business.

f. Special Projects. A special assignment, e.g., “to develop a system of dust collection in the foundry,” is highly useful and flexible training device.

g. Committee Assignments. Unlike special projects, committee assignments are regularly constituted. Committee assignments very well impart the necessary general background.

h. Selective Reading, e.g., going through Business Magazines, Trade Journals, etc.

(ii) Off-the-Job training and development which includes:

a. Attending special courses conducted at colleges and universities.

b. Role Playing. It involves constructing artificially a conflict situation in which the trainee is given a strategic position to play. Role playing increases the trainee’s skill in dealing with other people (e.g., Sales Training).

c. Sensitivity Training. It develops executive’s awareness and sensitivity to behavioural patterns of oneself and other people.

d. Simulation. Trainees are asked to make decisions about production, cost, inventories, sales etc., for a simulated firm.

e. Conference Training.

f. Attending Special Meetings of one or two days duration in various fields, e.g., Personnel, Production or Marketing Management, etc.