A project report on Materials Management. This report will help you to learn about:- 1. Meaning of Materials Management 2. Scope (Functions) of Materials Management 3. Importance 4. Objectives 5. Organization 6. Economy.

Contents:

- Project Report on the Meaning of Materials Management

- Project Report on the Scope (Functions) of Materials Management

- Project Report on the Importance of Materials Management

- Project Report on the Objectives of Materials Management

- Project Report on the Organization of Materials Management

- Project Report on the Economy of Materials Management

Project Report # 1. Meaning of Materials Management:

Materials Management is a function, which aims for integrated approach towards the management of materials in an industrial undertaking. Its main object is cost reduction and efficient handling of materials at all stages and in all sections of the undertaking.

Materials Management’s functions include several important aspects connected with materials, such as purchasing, storage, inventory control, materials handling, standardisation etc. Hence this subject has become very important and is gaining more and more importance.

Even three decades ago the term ‘materials management’ was little known and understood in the sense in which it is used today. Many terms, like purchasing, store-keeping, material handling etc. were used to denote more or less same meaning as that of materials management, but these terms were unable to give complete idea of materials management.

Materials management covers a very wide field and deals with materials cost, its supply, utilisation and handling. It is concerned with the planning and programming of materials and equipment, market research for purchase, procurement of materials (capital goods, raw material, components and semi-finished items), packaging, storage and inventory control, transportation of materials, salvage, material handling, disposal of scrap and surplus etc.

Project Report # 2. Scope (Functions) of Materials Management:

Following functions are included under the direction and control of Materials Manager, incharge of materials management department:

1. Materials planning and programming.

2. Store-keeping.

3. Purchasing.

4. Inventory control.

5. Simplification, codification and standardisation in stores.

6. Transportation.

7. Materials handling.

8. Disposal of scrap and surplus.

Looking to the above functions it is clear that Materials Manager has to work in close cooperation with different heads of departments.

For example he must co-operate with:

(i) Production Department

(a) For knowing what items, in how much quantity and at what times are required by him;

(b) And for inventory control;

(ii) With Sales Department, for transportation of outgoing material;

(iii) With almost all the Departments, for material handling operations throughout the undertaking;

(iv) With Sales and Production Department for the disposal of scrap and surplus;

(v) With Inspection and Quality Control Department to get the incoming materials inspected.

Project Report # 3. Importance of Materials Management:

A survey was conducted by the Directorate of Industrial Statistics during 1954-57 showed that the average materials cost is 64 per cent of the sales value. Thus only 36 per cent costs is for wages and salaries, overhead and profit etc. In some industries it costs upto 70 per cent. These figures themselves show the importance of materials management.

In addition to the cost of material (being 64 per cent), inventory carrying costs, come out to be 20 per cent of the material costs. Inventory carrying cost comprises interest charges on the cost of inventory, storage and material handling costs, costs of insurance, physical deterioration and obsolescence. Thus total material costs will amount to 76.8 or 77 per cent (64 per cent plus 20 per cent of 64 per cent) of the sales revenue.

In countries like Japan, inventory consciousness has proved to reduce materials cost substantially. In the year of application of scientific methods and techniques of materials management i.e. 1998—a saving of more than 3 per cent could be achieved in a period of merely 18 months. Thus in our country, it is very essential to develop inventory consciousness.

In addition to reduce material costs, efficient materials management is useful for following purpose:

(a) For reducing foreign exchange, by utilising the imported items to their maximum value and thus help in reducing the imports.

(b) By reducing the cost of finished goods and maintaining the quality, it is possible for Indian manufacturers to compete better in foreign market and earn more foreign exchange.

Up till now efforts have been made for saving in the wages (wages are about 16 per cent of sales value), which was not liked by the labour class and such steps created the labour problems. But the above facts show that more efforts must be made for the saving in materials cost (about 77 per cent) by utilising the techniques in materials management and that too without creating any labour problem.

Materials management resulted in increased productivity of capital by preventing large amount of capital locked up for long periods in inventories.

Project Report # 4. Objectives of Materials Management:

The objectives of Material Management as such should be supported in every way by:

(i) Maintaining continuity of productive operations by ensuring a uniform flow of materials.

(ii) Reducing materials costs by systematic use of scientific-techniques.

(iii) Releasing w irking capital for productive purpose by efficient control of inventories.

(iv) Increasing the competitiveness of end products by ensuring right quality at the right price, especially in foreign markets.

(v) Saving foreign exchanges through economic use of foreign purchases and import substitution.

(vi) Establishing good buyer-seller-relations.

(vii) Ensuring low departmental costs and high efficiency.

(viii) Setting high ethical standards. In this way it is clear that Materials management covers all aspects of materials, including, flow, materials cost, quality, supply, conservation and utilization.

The prime objective is to supply the user department with the required quantity of material at a constant rate with uniform quality so that production or service rendered is not held up. At the same time materials manager has to ensure the optimum usage of facilities like capital, storage space and other aspects of materials management.

Materials management offers a wide scope for reducing costs, saving the foreign exchange, conserving scarce materials, improving productivity and increasing profits. It is much easier to reduce material costs than to reduce labour costs and as material costs predominate in the total cost of a product, the saving is substantial.

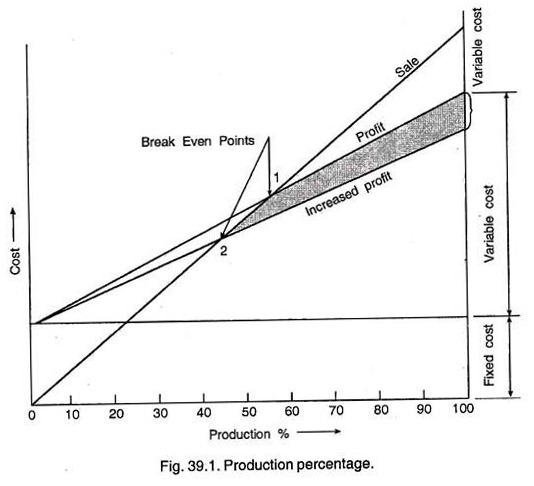

By careful financial analysis, it can be shown that a 5% reduction in materials costs will result in increased profits equivalent to a 36% increase in sales. The Break-even chart shown in Fig. 39.1 indicates that a substantial increase in profits can be obtained with a small decrease in material costs. The chart also shows that profit starts coming much easily if the Break-Even point is shifted backward with the same total production.

Increased production and sales are necessary to bring about the same increase in profits which result in reducing material costs or increasing production and sales to the extent of 30% to 40% which is not easy.

Increased production may need increase in fixed assets and increasing sales to that extent, may not always be possible without extra sales efforts like Additional Advertising which increases sales expenses. Further it depends more on external-environments over which the management has little control.

The primary task of the modern materials management, with an integrated view is purchasing material of:

Right Quality, Right Material, At the Right Price, From Right source, At the Right Time, Using Right Mode of Transport.

Storing the materials in the different warehouses with appropriate methods also forms an important aspect of materials management, since uncontrolled Inventory is “Industry Cancer.” The Materials manager is also responsible for the right quantity of inventory norms, i.e., for fixation of safety stock, re-order point, reorder quantity, etc.

Project Report # 5. Organization of Materials Management (MM):

For the purpose of planning, direction, control and coordination of various activities related to material in an enterprise, there should be a separate department of material management. The organizational structure of a MM department depends upon the size and nature or organization.

Organizational structure of materials management department may be based on:

(a) Commodities

(b) Functions

(c) Locations.

1. Organization Based on Commodities:

In this type, materials are generally classified as, raw material, consumables, fuels, imported items, spare parts, bought-out components etc. or as electrical items, cement, steel, chemical items, spares, consumables, machine tools, fuels, etc.

2. Organization Based on Functions:

In such organizations, MM department is divided into sections based on functions like; purchase, stores, inventory control, material planning, materials handling (or transport), value engineering and cost reduction etc.

These sections are further sub divided into sub-sections based on functions like, purchase section into source development, vendor evaluation, tendering, evaluation and issue of orders, follow-up, importation, procurement of capital equipment, spares procurement etc. depending upon the nature of work and quantum of work in the department.

3. Organization Based on Locations:

When an enterprise has more than one plant located in different locations, they can have either centralized MM department at the head quarter or decentralized set-up at each location.

Where materials management hold a key role in the organization and is considered as a prime activity, the materials manager is a senior level authority, and directly reports to the chief executive. In this case he is treated at par with production, marketing, finance and personnel.

In small scale industries, the function of materials management is considered subordinate to the production function and in such cases the materials manager acts as a subordinate to works manager.

Generally, MM department has various sections, depending upon the nature of work, such as purchase, receiving, stores, inventory control, value engineering and cost reduction, shipping etc.

Functions of Material Management Department:

The functions of materials manager are basically economic, even in non-profit organisations. The most fundamental objective is survival. The materials function also contributes to survival and profits by providing materials at the lowest total cost.

The materials function also helps to achieve the objective when it boosts inventory turnover or gets materials of superior quality. Following are some of the objectives of materials management which contribute to the achievement of some overall company objectives.

If the contribution is made directly by the materials function we call it a primary objective. If it is indirect and results from the materials department’s assistance to another department we call it a secondary objective.

Primary Objectives of Materials Management Department:

There are at least nine primary objectives of materials department. These are low prices, high inventory turnover, low cost of acquisition and possession, continuity of supply, consistency of quality, low pay roll costs, favourable relations with suppliers, development of personnel and maintenance of materials management records.

Secondary Objectives of Materials Management Department:

The secondary objectives of materials management are not so limited in scope and variety as primary objectives. Since they represent the materials department contribution to the achievement of the primary objective of some other departments, they can vary from industry to industry. Among the more common ones are economic make or buy decisions, promotion of standardisation, product improvement; effective interdepartmental relation etc.

Duties and Responsibilities of Materials Manager:

The number and kind of duties and responsibilities assigned to the materials manager depend to a considerable extent on the nature of his company’s product and the level of management to which he belongs.

The duties and responsibilities of materials manager generally include:

(i) Establishing and supervising materials management functions and procedures in line with company policies.

(ii) Internal organisation of materials management department so as to function efficiently in carrying out purchasing policies and procedures.

(iii) Organising and supervising departmental activities as the selection of vendors, placing of orders, expediting, store-keeping and the approval of invoices for payment.

(iv) Development of sound supplier relationships.

(v) Co-ordination between materials department and other departments of the company. The head of the materials management department frequently serves on company’s committees such as Product Development; Value Analysis; Budget committee and Quality assurance committees.

(vi) Preparing and analysing forecasts of supply conditions and price trends. The purchasing agent may also be responsible for establishing forward-buying policies in the light of these trends or he may serve as a member of a company committee that establishes these policies.

(vii) The auxiliary activities as disposal of scrap and surplus materials, inspection of incoming shipments, and traffic routing for incoming shipments are also frequently assigned to the materials manager.

(viii) Simplification, standardisation, and specification tasks in connection with materials and supplies that are purchased are sometimes the responsibility of materials manager.

(ix) Application of Electronic Data Processing; Computerisation and other Operations Research techniques for effective utilisation of various resources available to the materials manager.

The work of materials management department is broken down and assigned to other executives down in the hierarchy viz. Assistant Materials Manager; Senior Purchase Officer; Purchase Officer; Assistant Purchase Officer; Expediter; Production Coordinator; Materials Controller; Purchase Clerks etc.

Qualifications for Materials Management Department Personnel:

The qualifications for various executives and other supervisory staff in materials management department may conveniently be grouped into three categories—Personal characteristics; Educational background, and business experience relevant to materials management functions.

The personal characteristics that promise success in purchasing are no different from those in any other field of business. The difference is likely to be in importance attached to some of the characteristics.

It is unlikely that any experienced materials manager would agree precisely with the following personality traits:

(i) Integrity:

Materials manager expend huge some of company money. They must be impervious to the financial temptations that accompany such a position of trust, whether in the form of an inordinate gift, or outright bribery. Personal integrity is also required to refrain from making unwarranted promises to potential suppliers in order to secure preferential treatment.

(ii) Dependability:

The personality trait is important in purchasing personnel because frequently the continuity of operations of an industrial plant depends on the reliability of materials management department in following through on requisitions until goods are delivered according to specifications.

(iii) Initiative:

Purchasing personnel are constantly faced with situations demanding initiative and imagination. The continual search for alternative sources of supply is one such area where initiative is of importance.

(iv) Tact:

Many materials managers consider tact the most important personal trait. The reason for this is the crucial importance of maintaining sound and friendly vendor relations.

(v) Industriousness:

Knowledge of materials and sources is acquired only after extended training and experience. The industriousness of materials management department is tested by the long hours they must work.

In addition to the above traits, the executives in materials management department should possess: Ability to learn; Ability to work on details; Possess good human relations skills.

Education:

Present educational trend is toward employing professionally qualified personnel as management trainee. Such trainees possess the post graduate qualification in management with specialisation in materials management.

Most of trainees possess degree in engineering or science before completing their Business Administration qualification. Such trainees are provided one to two years training in various areas of materials management before appointed as first level executives.

Business Experience:

Business experience is almost universally considered to be necessary for materials management in the higher-ranking position. Some of the large companies secure employees for positions in executive cadre by building up a pool of professionally qualified college graduate as trainees.

These trainees are enrolled in an extended programme of indoctrination and work training, which rotates them through the major subdivisions of the company. During the training period those with an aptitude for and an interest in purchasing work can be selected out of the larger group and eventually assigned permanently to the purchasing department.

Project Report # 6. Economy in Materials Management:

Some of the ways to achieve economy in materials management are as under:

1. With large size orders the organization can get more discount, further, cost of transportation and cost of purchasing process is also reduced.

2. If the source of material is nearer, the cost of transportation and inspection are less.

3. Inspection of materials before placing order and other measures prior to actual procurement of materials leads to economy.

4. Make or buy decision also lead to economy.

5. The scrap and waste materials should be properly controlled, if possible, these may be used for some other inferior works.