A project report on Total Quality Management (TQM). This report will help you to learn about:- 1. Introduction to Total Quality Management (TQM) 2. Meaning of Total Quality Management (TQM) 3. History 4. Definition 5. Elements 6. Actions Necessary 7. Techniques 8. Model 9. Deming’s Approach.

Contents:

- Project Report on the Introduction to Total Quality Management (TQM)

- Project Report on the Meaning of Total Quality Management (TQM)

- Project Report on the History of Total Quality Management

- Project Report on the Definition of Total Quality Management

- Project Report on the Elements of Total Quality Management

- Project Report on the Actions Necessary for Total Quality Management

- Project Report on the Techniques for Total Quality Management

- Project Report on the TQM Model

- Project Report on Deming’s Approach to Total Quality Management

Project Report # 1. Introduction to Total Quality Management (TQM):

In order to capture increased market share, quality had been the main concern of every manufacturer since old days. Started with the inspection concept moved to the quality control concept, when it was realised that making the inspection department also responsible for quality of the product would be counterproductive.

Concept of quality control emphasises self-inspection and appropriate systems to ensure quality by identifying defectives and eliminating them. Help of statistical quality control and sample analysis were also undertaken.

Then arose the concept of quality assurance. But the quality movement did not stop with this, and the attempt is to continuously improve the quality and assure higher and higher standards of quality, offer better products to the consumer, ensure better and longer service, and improve the utility of the product.

It was felt that quality is not the job of quality control department only but other departments like sales, procurement, material handling, accounting, industrial relations, design, production, forecasting, marketing, stores, after sales service have also to contribute substantially.

Thus quality is the responsibility of all the employees. The workers should run the system, managers should design, and improve the systems, while top management should provide leadership and team spirit.

In a ‘Total Quality Management’ (TQM) concept, the word quality has a wider meaning, it means quality of output of every department and by every employee, cleanliness, orderliness, punctuality, customer service, standardization of works and continuous efforts for their improvement are also part of T.Q.M. In this, needs of the customer are constantly monitored to improve the products and processes to meet their requirements.

In Total Quality Management programme, voluntary participation of work people is sought for the quality of the task.

Effective T.Q.M. results in greater customer satisfaction, fewer defects, less waste, reduced costs, improved profitability and increased productivity. For the effectiveness of T.Q.M. programme a careful analysis of the customers’ needs, and an assessment of the extent to which these needs are currently met, and a suitable plan to fill up the gap between the current level and the expectation is necessary.

For the success of T.Q.M., top managers must provide vision, reinforce values emphasizing quality, set quality goals and deploy necessary resources for these quality programmes. For this purpose, training and development free flow of information is essential. The top managers must continuously monitor, evaluate, get feed-back about the T.Q.M. programme and take necessary steps for its improvement.

Customer’s satisfaction is the most important aspect of T.Q.M. The customer may be external to the organisation or may be inside the organisation. Meeting the needs of outside customers depend on meeting the needs of the inside customers. Inside customer is an individual or department receiving the output of another individual or department of the concern.

From the above, we can say that, the T.Q.M. involves effective decision making, problem solving and integration of Quality Planning, Quality Implementation and Quality improvement strategies of all the departments of an organisation, committed and involved employees, lower costs, higher revenue and high profits for the organisation.

Project Report # 2. Meaning of Total Quality Management (TQM):

Total Quality Management (TQM) is a very popular term which goes with the cultures of many manufacturing and service sectors. TQM is a philosophy, a set of tools and a process whose application yields customer’s satisfaction and continuous improvement as output.

The philosophy of TQM and the process differs from traditional philosophies and processes in that everyone in the company can and must practice it. TQM combines cultural changing tactics and structured technical techniques whose focus is on internal and external customers satisfaction.

An important requirement of TQM is that it requires the involvement as well as commitment of executive and not just their interest on implementation part. TQM in addition to satisfaction of all customer requirements so as to retain them, improves internal processes to increase profits and generates new business from new products, services and markets.

QMS scope covers all functions within an enterprise/industry from sales and marketing through design production and service. TQM aims to broaden the concept of quality so that quality moves from a product appraisal function to a corporate imperative for excellence.

There are three words in TQM-Total, quality and management.

By total we mean:

I. All areas/fields and functions in any unit/organisation.

II. All activities.

III. All employees/workmen.

IV. All time.

By quality we mean:

i. Product or services that satisfy the consumer requirements and expectations completely on a continuous basis.

ii. The above meaning of quality has completely changed its usual meaning that Quality means product produced exactly according to specifications.

By management we mean:

i. Quality does not come up at its own, it needs planning and management.

ii. Quality is a management function and everybody in the organisation is responsible for it. It therefore needs systematic approach.

Hence TQM is a people intensive activity.

According to Feigenboum TQM is defined as “effective system for integrating. The quality development, quality maintenance and quality improvement efforts of various groups in an organisation so as to enable production and service at the most economical level which allow for full customer satisfaction.”

Project Report # 3. History of Total Quality Management:

High customer demand for quality has been widely recognized as a main motive tor implementing corporate quality management. Yet, to satisfy such demand, innovative techniques and services alone are no longer sufficient. Rather, the whole system of management, from the top to the frontline operators, needs to be committed to achieving the corporate objectives and policies.

Total Quality Management (TQM) has been introduced worldwide as an option providing a new insight into quality management. Through such management, companies will improve their quality in terms of not only products and services, but also human resources and relationships. TQM seeks quality in long-term perspectives, through the strong commitment of all levels of employees to obtain corporate objectives.

The significant results of TQM application in large globally operating companies such as Ford, Chrysler, Toyota, Fuji Xerox, Philips, Panasonic (Matsushita), NEC, and Nissan have been widely recognized as success stories in company development. TQM has been introduced in many industries: not only in production, but also in service industry, as seen in the cases of Singapore Airline and some major banks.

Here, the concept of TQM will be introduced, followed by its overall objectives and procedures. The historical development of TQM provides an insight to TQM development worldwide. As a criterion to measure the development of TQM the Malcom Baldrige Award, the first national quality award in the United States.

Additionally, a comparative description of the Deming Prize in Japan will provide examples of different forms of quality award at the national level and how these awards contribute to the development of quality management systems in the country.

International Organization for Standardization (ISO) issues and their fusion with TQM and OCC are also crucial when one talks about quality. The basic relationship between the ISO 9000 series and TQM/OCC will be explained as a complement to these discussions on TQM activities.

Project Report # 4. Definition of TQM:

“TQM is a set of systematic activities carried out by the entire organization to effectively and efficiently achieve company objectives so as to provide products and services with a level of quality that satisfies customers, at the appropriate time and price.” (TQM Committee 2002)

“TQM” is an interlocking arrangement of procedures and practices that ensures that all employees in every department are adequately trained and directed to continuously implement aligned improvements in Quality, service and total costs, such that customer expectations are met (IEEE, 1993).

Total Quality Management is commonly expressed in conjunction with business excellence. It is a scientific management methodology that values the quality of companies and organizations-quality not only in products, but also in their processes and in their organization for quality management.

According to the TQM Committee, in the 21st century a company is to seek quality by establishing respectable existence and a co-delighting relationship with stakeholders (TQM Committee 2002, 37).

In order to accomplish this, the committee continues, “it is crucial that the company achieve competitive and praised ability, technology, speed and flexibility, and vitality.” And TQM has a significant role to play to meet those requirements.

TQM is a management method in which quality is required in all manners, to satisfy customer requirements. It involves every employee’s daily commitment in the office, which differentiates TOM from other management systems.

The term everybody here implies all levels in the organization from frontline operators to middle management to executive management. All of the problem solving processes by all parties contributes to strengthen the organizational capacity and management of the company.

TQM is not a program. It is “a strategy, a way of doing businesses, a way of managing, a way of looking at the organization and its activities”.

Therefore, the success of TQM is measured not only by its tangible outcome but also by both the way in which the organizational structure is established and the processes by which corporate objectives are achieved.

Project Report # 5. Elements of Total Quality Management:

1. Customers Satisfaction.

2. Employees involvement.

3. Morale of employees.

4. Quality Control Circles and suggestion system.

5. Higher revenue.

6. Lower cost.

7. Quality control.

8. Control of Production.

9. Quality planning.

10. Quality Improvement.

11. Quality implementation.

12. Quality Assurance System.

13. Vendor control and quality in procurement.

14. Customer relationship management.

15. Total organisation involvement.

16. Measurement information analysis.

17. Quality education and training.

18. Strategic quality management.

19. Leadership.

Project Report # 6. Actions Necessary for T.Q.M.:

In order to implement T.Q.M., following actions are necessary:

1. Adopt new philosophy of refusing to allow defects.

2. Create consistency of purpose for improvement.

3. Improving production and service quality should be a continuous process.

4. Cease dependence on mass inspection and adopt Statistical Quality Control.

5. Insist quantifiable evidence from the suppliers about their products.

6. All employees should be trained, retrained and refresher courses be arranged.

7. Provide proper tools to all the employees.

8. Adopt proper communication system.

9. Encourage productivity.

10. Encourage coordination between departments.

11. Permanent commitment of top management to quality.

12. Respect towards ‘work’ and ‘humanity’.

13. Adopt consumer orientation and not the product orientation.

14. Objective should be, ‘Quality first, and not the short term profits’.

15. Use facts and data.

Project Report # 7. Techniques Utilized for TQM:

The following is the list of techniques used for TQM:

1. Surveys of Customer’s satisfaction.

2. Quality function deployment.

3. Total quality seminars and quality training.

4. Cost of quality statement.

5. Departmental goal analysis.

6. Top team work shops.

7. Quality circles & suggestion schemes.

8. Visible data & process management.

9. Statistical process analysis.

10. Process capability analysis.

11. Just in Time manufacturing.

12. Fool proofing.

13. Quality Improvement Team (QIT).

14. Business Process Reengineering (BPR).

15. Standardization of production processes.

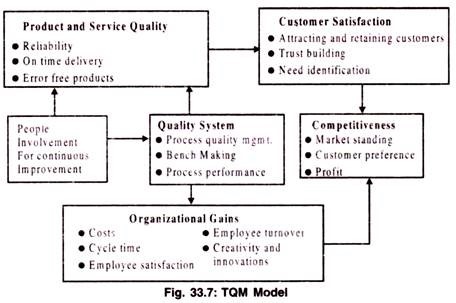

Project Report # 8. TQM Model:

The focus of TQM is customer satisfaction. Fig. 33.7 shows the model highlighting how the implementation of TQM benefits the organization in both long term and short term and at the same time achieves customer satisfaction.

Project Report # 9. Deming’s Approach to TQM:

Deming is among the pioneers of the TQM concept. His views on quality improvement consist of fourteen point approach as follows:

1. Aim at creating consistency of purpose for improving products and services.

2. Aim at adopting the new philosophy for making the accepted level of defects, delays or mistakes unwanted.

3. Aim to stop reliance on mass inspection as it neither improves nor guarantees quality. Remember that team work between the firm and its suppliers is the way for the process of improvement.

4. Try to stop awarding business with respect to price.

5. Aim to discover problems. Management must work, continually to improve the system.

6. Aim to take advantage of modem methods used for training. In developing a training program, lake into consideration such items as:

i. Aim at identification of company objectives.

ii. Aim at identification of training goals.

iii. Aim at understanding of goals by everyone involved.

iv. Aim at orientation of new employees.

v. Focus on training of supervisors in statistical thinking.

vi. Plan on team building.

vii. Aim at analysis of the teaching requirement.

7. Aim to institute modem supervision approaches.

8. Aim to tear down department barriers so that everyone can work as a team member.

9. Aim to eradicate fear so that everyone involved may work to his or her full capacity.

10. Try to eliminate items such as goals, posters and slogans that call for new productivity levels without improvement of methods.

11. Aim to make your organisation free of work standards prescribing numeric quotes.

12. Aim to eliminate factors that inhibit employee workmanship pride.

13. Aim to establish an effective education and training program.

14. Establish ways to develop a program that will push the above 13 points every day for never ending improvement.