Six Sigma method is a ‘measure of goodness’ involving the application of statistical methods to business processes to improve operating efficiency, reduce variation, avoid defects, and reduce waste. More specifically, it is a methodology and set of tools used to reduce quality problems to less than 3.4 defects per million opportunities (DPMO) or better.

Six Sigma is a management philosophy focused on business process improvements. It seeks to eliminate waste, rework, mistakes; increase customer satisfaction; and, finally, increase profitability and competitiveness. Six Sigma is a management philosophy aimed at customer satisfaction.

Learn about:- 1. Introduction to Six Sigma 2. Meaning of Six Sigma 3. Concept 4. Core Elements 5. Ten Principles 6. Pre Requisites 7. Levels 8. Six Sigma Belt 9. How Does Six-Sigma Work?

10. Phases of Six-Sigma Planning 11. How to Calculate Six Sigma? 12. Tools 13. Steps for Implementing Six Sigma 14. Roles and Responsibilities of People Responsible for Six-Sigma Implementation.

15. Approaches of Six Sigma 16. Difference between TQM vs. Six Sigma 17. Do’s and Don’t 18. Benefits 19. Criticisms.

Contents:

- Introduction to Six Sigma

- Meaning of Six Sigma

- Concept of Six Sigma Quality

- Core Elements of Six-Sigma

- Ten Principles of Six Sigma

- Pre Requisites of Six Sigma

- Levels of Six Sigma

- Six Sigma Belt

- How Does Six-Sigma Work?

- Phases of Six-Sigma Planning

- How to Calculate Six Sigma?

- 9 Key Six Sigma Tools

- Steps for Implementing Six Sigma

- Roles and Responsibilities of People Responsible for Six-Sigma Implementation

- Approaches of Six Sigma

- Difference between TQM vs. Six Sigma

- Do’s and Don’t of Six-Sigma

- Benefits of Six Sigma

- Criticisms of Six Sigma

What is Six Sigma: Meaning, Concept, Six Sigma Green and Black Belt, Process Tools, Levels, Steps, Principles, Benefits and Criticisms

Six Sigma – Meaning, Definition and Introduction

Sigma (σ) is a character of Greek alphabet, which is used in mathematical statistics to define standard deviation. The standard deviation indicates how tightly all the various specification (values) are clustered around the mean in a set of data. Six Sigma is an integrated, disciplined proven approach for improving business performance.

Six Sigma is a methodology for pursuing continuous improvement, by reducing process variability. The goal of six sigma is to increase profits by eliminating variability, defects and waste that undermine customer loyalty. Six sigma means recognizing the value of defect free business processes. Fewer defects mean lower costs and better quality which is need of customer and demand of competitive global market.

Six sigma was implemented in Motorola in 1987. It took five years to see the significant result of six sigma. Because of the implementation of six sigma and consequently better quality and reduced waste, Motorola attributes $15 billion in savings for Eleven years.

Many other companies which has adopted Six Sigma techniques are Texas Instruments, Allied Signal, ICICI, General Electric (GE) etc.

The six sigma can be very effective in manufacturing as well as service sector in order to reduce the number of defects or variations in a process.

Six sigma is a structured management technique for breakthrough improvement. The six sigma approach identifies the vital few elements that impact the bottom-line of the organization and with the structured, data driven, problem solving method improves the processes. It is highly disciplined process that helps us to focus on developing and delivering near perfect products and series.

In a company the cost of poor performance is computed to be 20-25% of total revenues. The six sigma approach implements proven methodologies for curtailing these costs while reaching world class quality levels by focusing on breakthrough performance.

Six sigma differs from traditional performance improvement program in its focus on input variables. While traditional methods depend on measuring outputs and establishing control plans to shield customers from organizational defects a six sigma program demands that programs be addressed at the root level, eliminating the need for unnecessary inspection and rework processes.

The fundamental objective of six sigma methodology is the implementation and a measurement based strategy that focuses on process improvement and variation reduction through the application of six sigma improvement projects.

Six Sigma – Meaning

Six Sigma method is a ‘measure of goodness’ involving the application of statistical methods to business processes to improve operating efficiency, reduce variation, avoid defects, and reduce waste. More specifically, it is a methodology and set of tools used to reduce quality problems to less than 3.4 defects per million opportunities (DPMO) or better.

Six Sigma is a management philosophy focused on business process improvements. It seeks to eliminate waste, rework, mistakes; increase customer satisfaction; and, finally, increase profitability and competitiveness. Six Sigma is a management philosophy aimed at customer satisfaction.

If a corporation is producing a product or service, which does not meet the customer’s needs, then it will not be competitive or profitable. Reworking a product or service as a result of inefficient processes not only results in increased cost of material, labour, and time but also in lost customers and poor reputation. It is the key to customer involvement.

It is not only important to gain a customer but also to retain one. From here, the corporation should go backwards and look at their processes to improve the product based on customers’ requirements. Once these processes are identified, then there must be a numerical, objective approach to evaluate current practices and future goals.

The Greek symbol σ (sigma) refers to the amount of variation in a process around its mean value. Statistics is a primary tool used in Six Sigma. In fact, the name Six Sigma is derived from statistics. Sigma is a Greek symbol, which denotes standard deviation, in other words, variation around the mean value, typically on a bell curve. Processes have acceptable upper and lower limits.

Six Sigma is about defining the best measures of a process, implementing them, tracking them, and making adjustments so that more of the outcomes fall in the acceptable range by reducing the number of defects.

Six sigma is a statistical and problem solving methodology that is focused on variation and defect reductions. While TQM focuses on detecting and correcting defects, six sigma re-creates the processes to ensure defects never arise right from the beginning. Six sigma is a broader concept of TQM, to achieve a new paradigm in customer quality.

Six sigma goes beyond defect reduction to emphasize business process improvement in general, which includes cost reduction, cycle-time improvement, increased customer satisfaction and any other metric important to the company.

An objective of Six sigma is to eliminate every molecule of waste that can be found in an organization’s processes. Customers form the base of today’s world market and sending a clear message – produce high quality products at lower costs with greater responsiveness. Six sigma helps an organization achieving these objectives when aligned with other initiatives as part of business strategy.

Six sigma is a breakthrough strategy that improves organizational values, infusing changes in the process, which go into creating defect free product or service at minimum cost.

For introducing Six sigma, it requires improvement in the following areas:

(a) Improvement of process

(b) Improvement of products and services

(c) Improvement in investor relationship

(d) Improvement in designing

(e) Improvement in supplier relationship

(f) Improvement in training and recruitment

Improvement in these areas usually represent dramatic cost savings to businesses, as well as opportunities to retain customers, capture new markets, and build a reputation for top performing products and services. Although it involves measuring and analysing an organization’s business process, Six sigma is not merely a quality initiative, it is a business initiative.

Achieving the goal of Six sigma requires more than small, incremental improvements. It requires breakthrough in every area of an operation. In statistical terms, ‘reaching Six sigma means that your process or product will perform with almost no defects. But the real message of Six sigma goes beyond statics.

Six sigma is a total management commitment and philosophy of excellence, customer focus, process improvement. Six sigma is about making every area of organization better able to meet the changing needs of customers, markets and technologies – with benefits for employees, customers and shareholders.

In brief Six sigma is:

(a) A statistical measure of the performance of a process or a product

(b) A goal that reaches near perfection for performance improvement

(c) A system of management to achieve lasting business leadership and world-class performance.

Six Sigma – Concept

In recent years, a new interest in basic quality principles emerged in many corporate board rooms under the concept of Six sigma; which is a customer-focused and result oriented approach to business improvement. Six sigma integrates many tested and validated quality tools and techniques, with a bottom-line orientation.

Six sigma can be described as a business improvement approach that seeks to find and eliminate causes of defects and errors in manufacturing and service processes by focusing on outputs that are critical to customers and a clear financial return for the organisation.

Some key concepts on which the core philosophy of Six-Sigma is based are:

1. Thinking in terms of key business processes and customer requirements with a clear focus on overall strategic objectives of the organisation.

2. Focusing on corporate sponsors, support team activities, helping to overcome resistance to change and obtaining resources.

3. Emphasising quantifiable measures such as defects per million opportunities (ppm) that can be applied to all parts of an organisation- manufacturing, engineering, administration, software etc.

4. Ensuring that appropriate metrics are identified early in the process and also ensuring that these metrics focus on business results, thereby providing incentives and accountability.

5. Providing extensive training and deploying a project team to improve profitability, reduce non-value added activities and achieve reduction of cycle time.

6. Creating highly qualified process improvement experts (such as master black belts, black belts and green belts) who can lead teams and apply improvement tools.

7. Setting stretch objectives for break-through improvement.

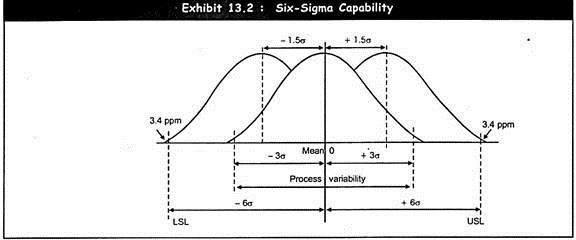

Exhibit 13.2 demonstrates this concept of Six-Sigma quality. If the process distribution is stable, that is, it remains centred between the specification limits, the proportion of the nonconforming product should be only about 0.001 ppm on each tail.

In real world situations, the process distribution will not always be centred between the specification limits, process shifts to the right or left are not uncommon. It can be shown that even if the process mean shifts by as much as 1.5 standard deviations from the centre, the proportion of non-conforming will be about 3.4 ppm.

Comparing this to a three-sigma capability of 2700 ppm demonstrates the improvement in the expected level of quality from the process. If we consider a product containing 1000 parts and we design it for Six-Sigma capability, then an average of 0.0034 defect per product unit (3.4 ppm) is expected, instead of the 2.7 defects expected with three-sigma capability.

Six Sigma – 11 Core Elements

Six-Sigma builds on a range of improvement methods that have proven to be effective.

The core elements of Six-Sigma approach are:

(i) Focus on the Customer:

Since Six-Sigma, measures start with customer satisfaction, the emphasis is on understanding customer expectations and requirements.

(ii) Date-and-Fact Driven Management:

Specking with data, management decisions based on fact and developing as in-depth understanding of internal processes are basic to Six-Sigma approach.

(iii) Specific Training:

Six-Sigma implementation requires trained people-both managers and workers- a defined and formal infrastructure consisting of champions, master Black Belts, black belts and green belts that head and influence Six-Sigma projects. Master black belts are the technical experts who provide training and support for other belts and also lead major cross-functional Six- Sigma projects.

The Black Belts undertake full-time work on Six-Sigma projects and lead the project team. The Green Belts are part-time process-owners and usually undertake work on a small scale, in contrast to the Black Belts.

(iv) Structured Approach:

Six-Sigma is based on a structured problem-solving approach. For existing processes, an approach known as ‘DMAIC’ approach consisting of steps “Define, Measure, Analyse, Improve and Control” is used and for new processes the steps include-Define, Measure, Analyse, Design and Verify-(called “DMADV” approach).

(v) Quality Engineering:

Six-Sigma was a full range of tools and techniques. Specific tools and techniques are used in each stage of the ‘DMAIC’ and ‘DMADV’ problem solving approaches.

(vi) Process Focus, Control and Improvement:

The key aspect is understanding the process in order to control its input and there by facilitate its improvement. It is important to examine potential defects, root causes and potential corrective and long-term actions. Also it is important to understand the relationship between inputs and outputs, with respect to issues such as which inputs have the biggest positive effect on which output.

(vii) Proactive Management:

An understanding of key principle of Six-Sigma is vital at all levels of management. Managers must be proactive in challenging why’ things’ are done in a certain way, defining root causes of problems, setting and maintaining aggressive improvement targets and devoting a large amount of their time for improvement projects.

(viii) “Boundary Less” Collaboration:

Since many Six-Sigma projects involve cross-functional teams, team work is essential and it is important to have a range of skills with in the team.

(ix) Drive for Perfection:

In the drive to eliminate defects, often things will go wrong and some projects will not achieve their goals. But it is important to understand the reasons for failure, to learn from experiments and take counter measures to prevent defects occurring in the future.

(x) Cost Savings of Each Project:

A sense of urgency is created with Six-Sigma, through the financial targets linked to each project. Therefore, each project should lead to verifiable bottom- line results.

(xi) Short-Term Improvement Projects:

It is necessary to fix a time-scale for each specific project’s completion. The duration of each project is relatively short- say between three and six months.

Six Sigma – Ten Principles of Six Sigma

1. Committed and strong leadership is absolutely necessary. This means a major cultural change in the organisation.

2. Existing initiatives, strategies, measures and practices must be integrated with Six-Sigma activities.

3. Data-based management having quantitative analysis and statistical thinking as key concepts.

4. Application of consistent effort to learning everything possible about customers and the market place.

5. Six-Sigma approach must produce a significant pay-off in a reasonable time period.

6. Highly trained individuals (referred to as Master Black Belts, Black Belts and Green Belts in that order of hierarchy) are necessary to lead at all levels of the organisation.

7. Systems that track, measure and report performance are needed to monitor progress, allow for needed course corrections and link the Six-Sigma approach to the goals, objectives and strategic plans of the organisation.

8. The organisation must have suitable reward and recognition systems that support continuous reinforcement of the people at all levels who significantly contribute to the viability and success of Six-Sigma approach. Compensation systems need to be reengineered in order to motivate employees.

9. Successes achieved due to Six-Sigma approach should be celebrated internally and frequently in the organisation.

10. Successful organisation should give wide publicity to its Six-Sigma achievements. This would further enhance the organisation’s image and self-esteem of its employees.

Six Sigma – Pre Requisites

Six-Sigma, like any other major organisational change programme, is not easy to implement successfully.

Success will depend on at least four major factors discussed in the following paragraphs:

(i) High levels of commitment and involvement of management:

Six-Sigma is based on an understanding of statistics which is not a popular area for most managers. Also, it is necessary that high-performing managers are released to be trained and after training that they commit a significant amount of their time to the implementation of Six-Sigma approach.

(ii) Six-sigma is not just another quality program or stand-alone activity:

Six-Sigma is not just theory or a mere training program, It is an active, involved effort that puts practical tools to work to root defects at all levels of the organisation. It defines analyses, improves and controls the vital few processes that matter most, to tie quality improvement directly to bottom line results.

Like TQM, Six-Sigma requires adherence to a whole philosophy rather than usage of a few tools and techniques. Six-Sigma is a business strategy that fosters a cultural shift at all levels. It changes the outlook and practices of everyone in the organisation.

(iii) Six-sigma is about reducing defects and improving quality:

Improvement depends on how opportunities for defects or failures are defined and measured. What matters in a Six-Sigma approach, as in any other quality approach, is what the customer wants or needs. The most critical effects or failures are those that cause maximum concern to the customer.

Increasing complexity of systems and products used by consumers created higher-than-desired system failures. Therefore, to increase system reliability and reduce failure rates, the components utilised on complex systems and products must have individual failure rates approaching zero, for example Six-Sigma approach to be used in an airline where the measure of failure needs to be defined.

(iv) Six-sigma involves a problem-solving approach:

Six-Sigma needs to be concentrated on those elements of a business which will result in customers perceiving that they would rather deal with them than with one of its competitors. Therefore, Six-Sigma, like any other performance improvement drive, should start from a strategy which is essentially a highly focused system of problem solving.

Six-Sigma is essentially about results- enhancing profitability through improved quality and efficiency resulting in high levels of customer satisfaction, improvement projects are chosen based on their ability to contribute to the bottom-line on a company’s income statement by being connected to the strategic objectives and goals of the corporation.

Six Sigma – Levels

Six Sigma at many organizations simply means a measure of quality that strives for near perfection. Six Sigma is a disciplined, data-driven approach and methodology for eliminating defects (driving toward six standard deviations between the mean and the nearest specification limit) in any process – from manufacturing to transactional and from product to service.

Motorola Inc., who first developed the methodology in the mid-late1980’s and who provide extensive Six Sigma training and consultancy services, provide the following definitions-

Six Sigma has evolved over the last two decades and so has its definition. Six Sigma has literal, conceptual, and practical definitions.

Six Sigma at three different levels:

a. As a metric

b. As a methodology

c. As a management system

Essentially, Six Sigma is all three at the same time.

a. “Six Sigma as a Metric- The term “Sigma” is often used as a scale for levels of ‘goodness’ or quality. Using this scale, ‘Six Sigma’ equates to 3.4 defects per one million opportunities (DPMO). Therefore, Six Sigma started as a defect reduction effort in manufacturing and was then applied to other business processes for the same purpose.”

b. Six Sigma as a Methodology- As Six Sigma has evolved, there has been less emphasis on the literal definition of 3.4 DPMO, or counting defects in products and processes. Six Sigma is a business improvement methodology that focuses an organization on-

i. Understanding and managing customer requirements

ii. Aligning key business processes to achieve those requirements

iii. Utilizing rigorous data analysis to minimize variation in those processes

iv. Driving rapid and sustainable improvement to business processes.

At the heart of the methodology is the DMAIC model for process improvement. DMAIC is commonly used by Six Sigma project teams and is an acronym for-

i. Define opportunity

ii. Measure performance

iii. Analyse opportunity

iv. Improve performance

v. Control performance.

c. Six Sigma Management System – Through experience, Motorola has learned that disciplined use of metrics and application of the methodology is still not enough to drive desired breakthrough improvements and results that are sustainable over time. For greatest impact, Motorola ensures that process metrics and structured methodology are applied to improvement opportunities that are directly linked to the organizational strategy.

When practiced as a management system, Six Sigma is a high performance system for executing business strategy.

Six Sigma – Six Sigma Belt Classified: Green Belts, Black Belts, Master Black Belts and Six Sigma Champion

In six sigma organization there are three basic level of training and six sigma hierarchies. These levels derive their names from the Japanese martial arts-green belt, black belt and master black belt.

The six sigma belts are classified into following categories:

1. Green Belts.

2. Black Belts.

3. Master Black Belts.

4. Six Sigma Champion.

1. Green Belts:

Six Sigma Green Belts are six sigma team leaders capable of forming and facilitating six sigma teams and projects from concept to completion. Green Belts are not full time positions. Green belts help assists black belt projects. Generally Green belts are focusing on 1 to 2 projects to be accredited.

For becoming Green belts, they are required to complete five days classroom training and it is conducted in conjunction with six sigma team projects. Training modules cover facilitation techniques and management of meetings, project management, quality management tools, quality control tools, problem solving tools.

2. Black Belts:

Six Sigma Black Belts are leaders of teams responsible for measuring, analyzing, improving and controlling key processes that influence customer satisfaction and productivity growths. They are specialist and experienced in using six sigma tools and techniques. They have generally a good experience in statistical techniques, problem solving techniques etc.

They have good leadership and team building skills. A black belt employee is trained in the DMAIC methodology. Black belt is expected to master a wide variety of technical tools in a relatively short period of time. Black belts generally give training to green belts and receive it from Master Black bets.

The desirable skills of Black belts are customer advocacy, self-motivation, team leadership, project management expertise, technical and numerical aptitude, good problem solving ability and result oriented.

3. Master Black Belts:

Master Black belts are the persons with the highest level of technical and organizational proficiency. In Motorola, the master black belt is a person who has practised as a black belt for five years.

This employee is a full time practitioner in six sigma tools and has been mentor to at least five black belt candidates. They should be sound on mathematical theory and statistical techniques.

A master black belt is a leader in the implementation of six sigma methodologies and is usually trained by the six sigma institute. Because of nature of duties, the master black belt is required to have good communication and teaching skills apart from mathematical skills.

4. Six Sigma Champions:

In addition to different sigma belts, there is one more quality agent who also contributes to six sigma effort, i.e. six sigma champions.

Business leaders who lead six sigma by sponsoring projects are called champions. Champions are trained in essential of the six sigma methodology focusing on selecting the projects that are aligned with business goals. Champions must select and mentor six sigma project leaders called belts.

Six Sigma – How Does Six Sigma Work?

The first step in the break- through strategy is to ask a new set of questions, questions that take the managers out of their comfort zone and ultimately provide them with a new direction. Six- Sigma forces business to let go of bad habits. Bureaucracy becomes delayed. Those employees who are closest to the actual work and to the customer become motivated to meet or exceed consumer requirements.

By questioning the speed with which products are produced and services are rendered, people begin to think about new systems that can be put into place to produce a higher-quality product or service in a shorter amount of time.

People who are close to the work discover more effective and profitable ways of working, and are able to inform top management about what changes need to be made and as a result, push those higher in the organisation to reexamine the ways in which they do business.

Six-Sigma is about asking tougher and tougher questions until we receive quantifiable answers that change behavior. Through Six Sigma, companies relentlessly question every process, and every step along the way to creating a final product. Managers, employees and customers ask different kinds of questions of each other than they have asked before.

As Six-Sigma takes hold across an organisation it creates an internal infrastructure that includes executives, managers, engineers and operations and service personnel. When 50 percent or more of an organisation’s staff embrace Six-Sigma, those individuals are able to mobilise massive changes in the way business is done, dramatically increasing profitability.

The methodology behind Six-Sigma is designed to pave way to find the right answers for the company. When an organisation starts to question what it does and why it does it, it can begin to lay a road that will lead to its own long-term goals.

The fact is, organisations need ways of measuring what they claim to value. Measurements or “metrics” carry relevance to every member, for every activity of an organisation. “You can’t change what you can’t measure”. The foundation of Six-Sigma uses metrics to calculate the success of everything an organisation does.

Exhortations won’t change things for the better, only measuring the things a company values can produce quantum changes.

Without measuring a company’s process, – and its changes to these processes, – it is impossible to know where you are or where you are going – Six-Sigma tells us –

i. We don’t know what we don’t know

ii. We can’t do what we don’t know

iii. We don’t know until we measure

iv. We don’t measure what we don’t value

v. We don’t value, what we don’t measure.

So in a general way, Six-Sigma is a process of asking questions that lead to tangible, quantifiable answers that ultimately produce profitable results.

To date, every company that has followed Six-Sigma methodology has achieved breakthrough profitability.

Six Sigma – Phases of Six Sigma Planning

After getting ready for Six-Sigma, the company needs to know how to plan for it. There are certain phases in Six-Sigma planning which serve as the foundation for any implementation and each phase consists of certain steps that build separately to launch the Six-Sigma project.

1. Communication and Education:

One of the best ways to build awareness about Six-Sigma is through a company-wide communication from the CEO or president of the company. Once this has been done, Six-Sigma is further introduced in key sessions to managers and executives to reinforce their understanding and support.

All senior managers need to undergo “Champion training” and managers at all levels need to undergo “Executive training”. “Executive training” should include an overview of Six- Sigma review of ease studies, related product and service demonstrations, strategies for deployment of Six-Sigma and exploration of tools and methods, statistical analysis, improvement, measurements and management controls.

“Champion training” provides the managerial and technical knowledge necessary to plan and implement Six-Sigma and mentor black belts This training covers principles, tools and applications of Six-Sigma including deployment tactics and strategies for establishing metrics., selecting black belts and projects and implementing Six-Sigma. The next steps in this planning phase are to order training materials, select black belt candidates and schedule training programmes.

2. Identification of Projects:

The planning phase also involves selection of Six-Sigma projects using appropriate process to identify the chromic issues that the Six-Sigma project teams should investigate and improve. If needed, support of outside consultant may be sought to select the projects that have high impact on quality and customer satisfaction and will deliver bottom-line savings. Further to identifying the projects, the departments and people needed for supporting these projects should be identified.

3. Infrastructure:

“Job descriptions” for the new roles of the black belts must be developed and these black belts must be posted to the selected Six-Sigma project teams. Human measures department must also benchmark compensation plans that reward black belts and their teams upon successful completion of Six-Sigma projects.

Once the black belts are selected, their compensation plans are decided, the training phase will begin based on what the project will entail. The objective of training black belts is to create technical leaders, advanced users and teachers for Six-Sigma.

The black belts should learn Six-Sigma philosophy, application tactics (including statistics, benchmarking, process control techniques, diagnostic methods and experimental design) and group dynamics. After undergoing training, the black belts are assigned to the selected projects.

The support of an experienced master black belt (usually provided by an outside consultant) is crucial to the success of black belts. A “master black belt” will guide and coach the “black belt” candidates and work with ‘champions” to help overcoming barriers and obstacles.

Periodic review meetings involving top management, other champions, senior leaders, and outside consultant are held to discuss the progress of Six-Sigma initiative and to ensure that the teams are meeting the objectives.

4. Implementation Partner:

Each Six-Sigma deployment follows the same success model for implementation. The specifics of a particular situation, the projects selected and the champions and black belts will determine how a plan is created and all activities are scheduled. An outside consultant directs, trains and executes the critical elements of the planning process.

The consultant acts as implementation partner and helps to orchestrate all responsibilities, roles and schedules to make a smooth transition from planning phase to implementation phase. The outside consultant or implementation partner should be focused on knowledge transfer, on sharing how to solve problems through the most effective methods and fix process defects with the right tools.

Six Sigma – How to Calculate Six Sigma? (With Example and Formula)

Sigma (σ) stands for standard deviation. Standard deviation is a statistical way to describe how much variation exists in a set of data, a group of items or a process. Six sigma is a breakthrough strategy that leads to defect free products and services, adding profit to the organizations and satisfaction to the customers. However no organization can achieve Six sigma level right at the beginning. It requires relentless efforts to achieve each sigma level and then ultimately the desired Six sigma level, at which products/services are virtually defect free.

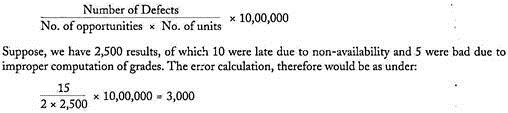

For calculating sigma level, we use the ‘Defects per Million Opportunities (DPMO)’.

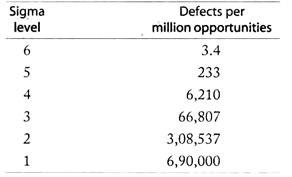

The following table shows the levels of sigma performance:

For example- if your company processed 2,50,000 credit card bills a month and operated at 99.38 per cent accuracy (4 sigma), you would have about 1,550 unhappy customers every month. Six sigma recognizes that there is always some potential for defects, even in the best run processes or best built product. But at 99.9997 per cent performance, Six sigma sets a performance target where defects in many processes and products are almost non-existent.

Once quantitative details about number of units and defects are made available we can use the following formula to calculate the sigma level:

For Error:

Therefore, 3,000 DPMO almost corresponds to 4.25 sigma level, which indicates, the firm needs to identify further the process flows and improve upon the quality of service. In this case, number of opportunities for error has been taken as ‘2’ (i.e. non-availability of assignment grade and improper computation of grades). Number of defects is 15 (i.e. 10 + 5).

Six Sigma – 9 Key Six Sigma Tools

The overall Six-Sigma methodology is implemented by using a specific set of statistical tools throughout each phase of the DMAIC model.

Taking the Six-Sigma journey requires a map which is made up of a set of specific analytical tools that direct the course of all the efforts and point to the path to be followed to improve the processes.

These are the first tools to be used in Six-Sigma approach at the beginning of the project to conduct initial investigations into a specific process. The key types of tools are basic statistics, graphical analysis and simple correlation studies. These warming tools help us begin to understand and represent the data obtained from measuring a process.

Basic statistics involve the understanding and use of measures such as ‘mean’, ‘mode’ and ‘median’. Graphical analysis uses a key warm up tool – the histogram to represent data graphically. Histogram shows the distribution of elements in the process.

When we calculate the mean, the mode, and the median we are measuring the central tendency of the data. To measure the dispersion of data, we need to calculate “range” “variance” and “standard deviation”.

The ‘standard deviation’ is the most commonly used measure of spread or dispersion. Another means of discovering patterns in a graphic form is the “run chart” – Run Charts are used to analyses processes according to time or order and reveal patterns that occur over time.

Simple correlation study is also classified under warm-up tools. Correlation as a statistical concept is the degree to which variables are related. For factors to correlate there must be a cause and effect relationship, not just a coincidence. The input must affect the output. Correlation also describes direction as well as linkage.

However it must be remembered that correlation does not necessarily mean causation. A correlation study is used to quantify the relationship if any between two sets of data points. An example of graph used in correlation study is a ‘scatter plot’ or scatter diagram which provides a good visual display between two sets of data points.

The warm up tools are used to find out fundamental information about a process, including the average and spread of data and then understanding cause and effect relationships. These steps serve as the building blocks for all the rest of the Six-Sigma actions.

The key tools used to track down defects and quantify them are discussed in the following paragraphs:

Key Tool No 1- Process Mapping:

This tool is used during the “Measure” phase of DMAIC. Process mapping is an integrally important tool that helps us to understand every aspect of every input and output. It helps to document the process in order to maintain control and reduce variation due to changes over time, process mapping is done through a flow chart which shows operations, decision point, delays, movements, rework loops and controls or inspections. By breaking down the process into steps, the flowchart simplifies analysis of the process.

Key Tool No 2- The XY Matrix:

It is also called as the “House of Quality” which is another tool used in the “Measure” phase. XY matrix is used to link the customer’s “critical to-quality” (CTQ) requirements to the process inputs, to ensure that we have the right set of priorities in the process improvement activities.

Two techniques used in XY matrix are:

(i) Brain-storming and

(ii) Cause-and-effect diagram.

Brainstorming is a method for generating ideas. Participants in the brainstorming session focus on a problem or an opportunity and come up with as many ideas as possible and push the ideas as far as possible. Participants can build on each other’s ideas. Then after brainstorming, the team can analyse the results and explore the best ideas. Brainstorming is a valuable tool for probing during the “Analyse” phase and for generating ideas during “Improve” phase.

Cause-and – Effect Diagram is a graphical tool which can be used to identify the relationship between a problem and possible causes of the problem.

The purpose of using the XY matrix is to study and understand the relationship between what we are putting into a process and what our customer is getting out of it. The XY matrix allows the team to identify gaps and areas for improvement.

Key Tool No 3- Measurement Systems Analysis (MSA):

This tool helps to ensure that the measurement system is statistically confident – that it is both accurate and precise whenever it is used. Undertaken during the “Measure” phase, this tool determines whether or not we can make a certain measurement and repeat or reproduce it among different people who take the same measurement.

Within the MSA tool there is another specific tool – the gauge repeatability and reproducibility study, which compares our measurement devices against others.

Key Tool No 4- Process Capability Tool:

Process capability is the measure of process being able to meet required specification and fulfill CTQ needs on a long-term basis. Process capability analysis uses a series of steps to establish short and long term deviation patterns and baseline performance for each process.

The tools determine whether or not the process is performing within the specifications, show how to decrease variation and help to chart the direction necessary to reach optimum capability.

Pareto Chart:

Gives graphical representation of the relative importance of process causes or defects based on Pareto Principle 80-20 rule. Pareto Chart is used to identify factors in a process that the greatest cumulative effect so that we can focus on a few important factors (vital few) rather than the trivial many (80 percent of problems result for 20 percent of causes).

Key Tool No 5- Multivariate Study:

This is an analysis which offers a way to reduce possible causes of variation in a process to a family of related causes, by graphing the interrelationship of multiple variables. The multivariate studies look at sources of variation within a piece or batch, variation from piece to piece and variation related to time (temporal) to discuss which one contributes the most to that variation.

Multivariate studies compare how the same functions, performed by different people or in different shifts, perform over time. This tool is used in the beginning of the “Analyse” phase.

Key Tool No 6- Hypothesis Testing:

This tool is used in the “Analyse” phase. This involves procedures for making rational decisions about possible causes of a given effect. Hypothesis testing involves a logical sequence of steps defining the problem, statistically testing whither or not the probability of defect caused by random chance or has a more tangible cause hidden in the process. One of the ways to test hypotheses is through simulations.

Key Tool No 7- Failure Mode Effect Analysis (FMEA):

Failure mode effect analysis takes place during the “Analyse” phase. It is the manner in which a part or process can fail to meet a specification, creating a defect or non-conformance, and the impact on the customer if that failure mode is not prevented or corrected.

It is a method for designing in reliability while minimising causes of failure. Preventing failure modes prevents defects. FMEA charts the type of effect, severity of defect, probability of occurrence and whether or not systems are in place to properly detect it.

Key Tool No 8- Design of Experiments (DOE):

This tool is used in the “Improve” phase. It helps to identify and quantity the effect of the X’s on the ‘Y’s. It helps to determine which inputs are significant in affecting the output of a process. It also helps to quantify the values of the input variables to meet the output requirements.

DOE is a way of determining and measuring the importance of two or more factors on the outcome of a process, by experimenting with many factors and variables simultaneously.

Key Tool No 9- Control Plan:

This tool is used in the ‘control’ phase which is the concluding phase of DMAIC. It improves quality by doing a thorough evaluation of process characteristics and variation sources. It helps to increase customer satisfaction by focusing resources on process and product characteristics that are important to customers.

Control Chart are used to indicate the range of variability that is built into a process known as common cause variation). It helps to determine whether or not a process is operating consistently or if a special cause has occurred to change the process mean or variance. Control Chart is a fundamental tool of statistical process control.

Six Sigma – 5 Steps for Implementing Six Sigma

Bedi (2008) proposes the following five steps while implementing six sigma in organizations:

Step 1 – Define the priorities of the customers with respect to quality. In this step, attributes of the product that are considered the most important by customers in evaluating the quality of the product are identified. These attributes possess critical to quality (CTQ) characteristics. The customers’ perception of quality attributes is periodically updated by way of customer survey.

Step 2 – Measure the processes and defects arising in the product due to process. The important processes influencing/affecting the CTQ characteristics are identified through the performance measurement techniques that are established for these processes.

Step 3 – Analyse the process to determine the most likely causes of defects. The key variables most likely to responsible for variation in the process are identified to find the reason for defect generation.

Step 4 – Improve the process performance and remove the causes of the defects. Specification limits of the key variables are fixed and a system for measuring the deviations of the variables is established and validated. The process is improvised in order to keep the variables within specification limits.

Step 5 – Ensure that the improvements are maintained over time. The modified process is subject to vigil at regular intervals of time to ensure that the key variables do not show any unacceptable variations (beyond specification limits).

Six Sigma – Roles and Responsibilities of People Responsible for Six Sigma Implementation

The success of Six-Sigma relies on the people who are responsible for implementing it. Six- Sigma provides some powerful techniques and tools, but success depends on the people who play the primary roles and assume the central responsibilities for using those techniques and tools to work for their organisation.

Six-Sigma invariably disturbs the status-quo. It creates a major interruption as job descriptions are redefined and activities are radically changed in order to bring real, permanent changes. Everyone is a player in the implementation of Six-Sigma, regardless of individual organisational positions.

However, not everyone is slated for full Six-Sigma responsibilities. People should be chosen to run the projects, participate on teams and to pursue the objective using Six-Sigma tools like metrics and other statistical measurements. The right mix of right talents is needed to refocus on Six-Sigma projects.

Key Players:

Basically there are five categories of key players.

They are:

1. Executive Leaders- who commit to Six-Sigma and promote it throughout the organisation.

2. Champions- who fight for the cause of black-belts and remove the barriers if any

3. Master Black Belts- who serve as trainers, mentors, and guides.

4. Black Belts- who work full time on Six-Sigma projects.

5. Green Belts- who assist black belts on part-time basis.

6. Process Owners- individual who have the ultimate authority to change a process.

The roles and responsibilities of these Key Players are briefly discussed in the following paragraphs:

1. Executive Leaders:

The key role of executive leaders is to decide to do Six-Sigma and to endorse it publicly, throughout the organisation. They kick-off and reinforce the comprehensive scope of Six-Sigma to ensure participation and support of everyone in the organisation. Six-Sigma being a company-wide initiative involving major permanent changes, requires visible leadership to signal its importance to the organisation.

Executive leadership can be built on some essential aspects such as determination, confidence, integrity and patience. Executive leaders need to show determination in their actions. They need to be resolute in believing that Six-Sigma will succeed.

They should be determined to get the training, understand the savings, perpetuate the use of metrics and show-case achievements of black belts, mark key milestones and keep the overall initiative on track.

For example, Jack Welch, The CEO of General Electric in the US could be considered the ideal executive leaders for Six- Sigma. From the top down and throughout all points in the organisation, executive leaders can inspire and promote a’ Six-Sigma culture that continually produce results.

Executive Leaders need to actively display confidence-not only in the Six-Sigma method, but also in the people charged with making it work. The leaders show confidence with rewards and incentives and inspire sustained commitment and effort on the part of employees. This confidence exhibited by executive leaders acts as a powerful motivator. Executive leaders can validate their confidence in champions, black belt or project team by pointing out specific outcomes that emerge from project metrics.

Executive leaders must also need to show integrity in their actions. “They need to do what they say they are going to do”. This inspires ever-increasing confidence among project teams in the words of their executive leaders. Executive leaders demonstrate a high standard of ethical leadership of following through on commitments. Integrity stimulates loyalty and respect which are essential catalysts for employee motivation across the organisation.

Executive leaders must practice patience and be models to others even though this is difficult to practice in a business environment that demands quick results and solutions to problems. As Six- Sigma projects are time consuming exercises, skipping steps or rushing the process can prove disastrous.

By demonstrating their determination, confidence, integrity and patience, company executive can develop good relationship with their employees commanding respect and loyalty.

2. Champions:

The success or failure of a Six-Sigma project critically depends on the champions. A champion is an advocate who fights for the cause of black belts and to remove functional, financial or personal barriers so as to enable black belts to do their work efficiently.

Champions know the process very well and can be considered as the ‘owners’ of the process in every respect. The champions are drawn from the ranks of managers and executives depending on the size of the organisation. They are responsible for the daily oversight and management of each critical element.

They are responsible for reporting to top management about progress of the project and also for supporting their teams. They must ensure that the projects they select align with the executive strategy and can be easily understood and embraced by project teams.

Champions also have the responsibility of selecting black belt candidates, identifying project areas and establishing clear and measurable goals for the selected projects. They are also responsible for keeping the projects on schedule.

Champions must be fully involved in process. They identify and remove obstacles to enable Black belts to focus on their projects and achieve the bottom-line outcomes. The champion plays the role of an advocate and defender, a mentor and a coach; He is ultimately responsible for the success of the Six Sigma project.

While the black belts and project teams hunt for defects and waste, the champion selects the project and monitors its performance. Therefore the champions must have thorough knowledge of the strategy and discipline of Six-Sigma and also be able to educate others about its tools and implementation.

3. Master Black Belt:

Often, a member of the implementation partner’s (consultant’s) team may fulfill the role of Master Black Belt in the initial stages. He / She serves as the trainer, mentor and guide for the firm’s project team. The master black belt is responsible for selecting the right people and assisting in screening and selecting projects that will best achieve the firm’s objectives.

Once the firm has firmly established Six-Sigma activities in place and designated and trained people in their roles, started projects and achieved some desired results, the members of the project teams can be elevated to the rank of master black belts.

The master black belt has expertise in Six-Sigma tools and tactics and is a valuable resource in terms of technical and historical expertise. He plays the role of a teacher, mentor and lead agent of change and ensures that the required infrastructure is in place and black belts are trained. The focus of master black belt is entirely on process improvement.

A key aspect of the role of master black belt is the capacity to skill-fully facilitate problem solving without actually taking over a project. A master black belt is an important asset at the initial stage of a Six-Sigma initiative because of his/ her role in co-coordinating and collaborating with the champion, top management, advising and coaching black belts. He or she enables the champion to keep focused on what is important in selecting projects and implementing Six-Sigma.

4. Black Belts:

Black belts have multiple roles and responsibilities. They work full-time on selected projects. Black belts are not masters of the process under study but masters of the change process. They act as full-time change agents. They supervise the green belts working on a Six- Sigma project. Black belts are trained to dig into the chronic and high impact issues and fix them with Six-Sigma techniques and practices.

Other roles and responsibilities of a black belt are:

(i) Preparing a draft project charter for the Six-Sigma projects under his\her supervision.

(ii) Working closely with a project team to keep it functioning and progressing toward speedy and effective conclusion to the Six-Sigma project.

(iii) Communication with the individual responsible for the financial and political well-being of the team (called a champion)

(iv) Serving as the team leader for Six-Sigma projects because of his / her expertise in Six- Sigma theory, tools and method.

(v) Helping team members analyse data and design experiments.

(vi) Providing training to the team members in Six-Sigma theory, tools and methods.

(vii) Helping team members prepare for management reviews.

(viii) Recommending Six-Sigma teams for Six-Sigma projects.

(ix) Leading and coaching green belts dealing simpler Six-Sigma projects.

Selection of Black Belts:

Black belts are central to Six-Sigma projects with important responsibilities as technical experts, team leaders and project heads. Being a black belt is a full time discipline that combines leadership ability, technical skills and some statistical knowledge, the ability to communicate clearly and motivated curiosity.

Black belts are the technical leaders and change agents, the key players who implement the Six-Sigma principles, techniques and tools.

Successful black belts share the following traits:

(i) Ability to work well on their own and also in groups/teams.

(ii) Remaining calm under external pressure

(iii) Anticipating problems and acting on them immediately

(iv) Respecting their fellow workers and commanding respect by them.

(v) Inspiring others (team members)

(vi) Ability to delegate tasks to other team members and co-ordinate their efforts

(vii) Understanding and recognising the abilities and limitations of their fellow workers

(viii) Showing genuine concern for others, for what they need or want

(ix) Accepting criticisms well

(x) Having concern about the current processes and results and improving the systems

(xi) Having the intelligence and interest to learn how to apply Six-Sigma tools.

5. Green Belts:

Most green belts serve as team member on Six-Sigma projects. They assist black belts in their functional areas. They apply Six-Sigma tools to examine and solve chronic problems on projects within their regular jobs. They also help black belts in collecting or analysing data, running experiments or conducting other important tasks in a project.

However, if a green belt acts as a team leader for simpler projects, then he or she has the following responsibilities:

(i) Preparing a draft charter for the Six-Sigma project

(ii) Selecting team members for Six-Sigma projects

(iii) Communicating with the champion, black belt and process owners concerning the status of the project.

(iv) Facilitating the Six-Sigma project team members and

(v) Providing training to team members in basic Six-Sigma tools and methods.

A green belt spends one-quarter of his / her work time as a team member on one or more Six- Sigma projects.

Green belts are the “work horses” or “work bees’ driving bottom-line results.

A green belt must pass a certification examination and participate in at least one successful Six-Sigma project.

6. Process Owners:

A process owner is the individual who has the ultimate authority to change a process. The process owner should be identified for every project or task that is entered on to an organisation’s metric tracking system.

The roles and responsibilities of a process owner are:

(i) Monitoring the performance of his / her process through key indicators

(ii) Empowering the people who work in his / her process

(iii) Working with all Six-Sigma project teams in his / her area to enable them to successfully complete their projects.

(iv) Managing the process after completion of the Six-Sigma project to sustain the gains made by the Six-Sigma project team and

(v) Continuing to improve and / or innovate, his / her process through the application PDCA Cycle. A process owner should pass the champion certification examination because he / she should have Six-Sigma knowledge to be effective. A process owner must understand the PDSA cycle to accept a project from control phase of the DMAIC model.

Difference between Black Belt and Green Belt Six-Sigma Projects:

Green belt Six-Sigma projects tend to be less involved [e.g. they have one “Critical to Quality (CTQ) characteristic and up – steam variable (x)], do not deal with political issues, do not require many organisational resources, do not require significant capital investment to realise the gains identified during the project, and utilise only basic statistical methods.

On the other hand, black belt projects tend to deal with more complex situations that may involve two or more CTQs and many ‘x’s, may involve substantial political issues or be cross- functional in nature, require substantial organisational resources, may need substantial capital investment to realise the gains made during the project and utilise sophisticated statistical methods.

Six Sigma – Approaches

Six Sigma aims at improving processes and producing goods with zero defects. There are two methods to achieve this goal. The first is define, measure, analyse, improve, control (DMAIC) and the second is to define, measure, analyse, design, and verify (DMADV).

(1) DMAIC:

It involves defining the problem, measuring where you stand, analysing where the problem starts, improving the situation, and controlling the new process to confirm that it is fixed. The black belts attend four training sessions taught by the master black belts to clearly understand these steps.

These sessions are broken up so that the black belts can take what they learned and apply it to their initial projects. The theory behind this is that they are not overwhelmed with too much information all at once. Another good way to remember DMAIC is ‘dumb managers always ignore customers’.

The various steps are explained in this section:

i. Define – A numerical parameter must be used to define the problem. There must be an objective way to measure the problem. In addition, the goal is not to manage the problem but to solve it. Therefore, there must be a focus on the problem, not on the outcome.

ii. Measure – Again, a numerical measurement of the current process is necessary in order to change the process. What are the results of the current process? What are the competitor’s processes? The focus must be on the critical quality issues that the customer finds important.

iii. Analyse – Once the measurements are available, it is necessary to analyse this data. This will eliminate the gap between the current practice and the desired goal—achieving 3.4 defects in one million opportunities.

iv. Implement – After analysis, changes need to be implemented to achieve this goal. Everyone should be involved in suggesting ways to improve the processes, especially those that work directly with the process. The green belts and black belts in an organization act on these suggestions.

v. Control – Once changes have been made to the process to achieve new operating limits, then the black belt must oversee measures to keep these operating limits in place and then on to the next project in order to achieve the Six Sigma goal. This project is only one in several to incrementally achieve the Six Sigma.

Step of Six Sigma using DMAIC:

DMAIC means Define, Measure, Analyze, Improve and Control.

These are explained as:

1. Define:

It establishes a leadership team which will decide on project on which it will work. It also decides the factors like customer expectations, product quality, cost benefits etc.

The specific actions in this step are:

i. The problem statement, why the project needs to be done.

ii. Goal statement which include expected outcomes and results of project.

2. Measure:

In this step the team examines all aspect of project, develops a thorough understanding of it and identifies the critical requirement and processes. After establishing of these, the team defines performance measure for key characteristics and establishes an effective means of measuring them.

The various steps are:

i. Define your needs in terms of essential input for products.

ii. Set up of quality measures.

iii. Define the method for computing error with various tools like Pareto diagram, Histograms, charts, scatter diagram, etc.

iv. Measure current performance of process.

3. Analyze:

Team analyzers the data and lays the groundwork for improving the process. This step includes identification of sources and location of defects causing variables within the process.

4. Improve:

Team performs the following action in these steps:

i. Identification of process improvements.

ii. Designing a plan of action.

iii. Performing risk assessments on potential changes.

iv. Implementing the plan.

v. Monitoring the results after the recommended changes.

The improvements in the quality can be achieved in following ways:

i. Simplification of process.

ii. Improving the education levels of workers and employees.

iii. Eliminating the non-value adding activities.

iv. Improving the maintenance of machines and equipment’s.

v. Highlighting the need of various Quality programs.

5. Control:

The team reviews the entire process to ensure that the appropriate changes have been made and to identify the actions that will permanently maintain these changes.

(2) DMADV:

The various aspects of DMADV are define, measure, analyse, design, and verify.

i. Define – It involves the definition of internal and external goals of the customers and the project.

ii. Measure – Quantification of the customer needs as well as the goals of the management.

iii. Analyse – It involves the analysis of the options as well as the existing process to determine the cause of error origination and evaluate corrective measures.

iv. Design – It involves the design of a new process to the existing one in order to eliminate the error origination that meets the target specification.

v. Verify – This step involves verification, by simulation or otherwise, of the performance of the developed design and its ability to meet the target needs.

The difference between DMADV and DMAIC exists only in the way the last two steps are handled. In DMADV, instead of the ‘improve’ and ‘control’ steps, which focus on readjusting and controlling by one way or other, the ‘design’ and ‘verification’ steps deal with redesigning the process to fit customer needs.

At the crux of the Six Sigma programme, advanced by GE’s Jack Welch and instituted at many other major corporations such as Motorola, is a renewed focus on eliminating errors, waste, and rework. Six Sigma is based on designated teams (people power) that focus solely on solving specific problems (process power), which may lead to efficiencies that delight customers and, by saving the company money, enhance the bottom line.

What distinguishes Six Sigma from other popular quality management techniques, such as TQM and ISO 9000, is that each team has a clear goal; moreover, employees benefit because companies usually link financial incentives to a team’s goal.

Chowdhury (2001) has created a fictional story that exemplifies the benefits of Six Sigma. In this book, Joe, a middle-aged manager is unexpectedly laid off from his position at a fast-food franchise company. He is worried and anxious about his next move. He calls Larry, his old friend and former co-worker, whose career is thriving.

Over lunch, Larry explains how he has practised Six Sigma, both to advance his career and to increase profits for his employer. He teaches the programme’s basics to an initially sceptical, then wildly excited and enthusiastic Joe.

Six Sigma – Difference between TQM vs. Six Sigma

TQM and Six Sigma no doubt have their common objective of achieving high quality and continuous improvement. Both techniques uses statistical techniques to solve problem. Still there are some differences between TQM and Six sigma.

These are compared below:

TQM:

1. TQM is focused mainly on production design department etc.

2. It relies on self-directed work team.

3. Truly cross functional.

4. Quality oriented.

5. It does not focus on training in statistical techniques.

6. TQM frame work consists of co-ordinators, leaders, group member etc.

Six Sigma:

1. Six Sigma not only focused on manufacturing but also on service sector like banks, hospitals etc.

2. Six sigma relies upon executive ownership.

3. Largely within a single function.

4. Six sigma is mainly business result oriented.

5. Focuses mass training in statistical technique.

6. Six sigma has different organization structure like Green belt, Black belt, Master Black belt.

Six Sigma – The Do’s and Don’ts

The Do’s:

1) Do keep the focus on results

2) Do embrace customers

3) Do plan for success

4) Do communicate the commitment companywide.

5) Do demonstrate the commitment of company leaders.

6) Do empower your key human resources

7) Do provide on – site monitoring for black belts

8) Do choose an implementation partner (an outside expert) who will actively assist in serving and selecting Six-Sigma projects

9) Do be patient at the inception of your Six-Sigma initiative

10) Do claim and advertise early ‘wins’

11) Do bench – mark

12) Do establish project baselines and goals

13) Do get advance buy in from your controller.

Don’ts:

1) Don’t make Six-Sigma a massive ‘training’ exercise

2) Don’t take ‘Big-Bang’ approach to Six-Sigma

3) Don’t focus resources on reworking training material

4) Don’t let the controller waffle about your saving calculations.

5) Don’t skip steps.

6) Don’t be afraid to learn and use statistical tools.

The “do’s” and “don’ts” listed above are briefly discussed in following paragraphs:

The ‘Do’s’:

1. Do keep the focus on results:

It is important to have a clear vision of where a firm is and where it wants to be in terms of decreasing costs and increasing bottom – line profits. Usually, a qualified implementation partner (a consultant) may be helpful in using a project tracking system to monitor results. The firm needs to focus on a vital few factors rather than the trivial many.

2. Do embrace customers:

Achieving phenomenal business growth depends on how well the firm understands and meets those “critical-to-quality” expectation of its customers. The firm must constantly keep in touch with its customers and know what they want in terms of price, quality and delivery.

3. Do plan for success:

Proper planning is necessary to ensure that the firm will meet its goals. Planning provides the milestones and progress reports that indicate how well and fast the firm is reaching its goals.

4. Do communicate the commitment company-wide:

It is important that the firm communicates with every employee and lets them know what the firm is doing and intending to accomplish. From the CEO to the worker in the production line-every employee should have a sense of ownership of the Six-Sigma projects undertaken and there should be time commitment and enthusiasm at every level.

5. Do demonstrate the commitment of company leaders:

The leaders of the firm (top management) should actively show their own commitment to the success of Six-Sigma implementation. The leaders show their commitment by serving as mentors and champions, allocating the needed company resources and breaking down barriers to support Six-Sigma projects.

6. Do empower key human resources:

Right people must be selected to lead the Six-Sigma project teams. These key persons must be empowered. The black belts and team members should be provided with the essential quality tools for the implementation of Six-Sigma projects through the phases-Define, Measure, Analyse, Improve and Control (DMAIC)

7. Do provide on-site mentoring for black belts:

The top management must assure their black belts total support for their projects. The black belts must have access to information or data -both from within the firm and form outside, and their interpretation of it must be unrestricted.

8. Do choose an implementation partner who will actively assist in screening and selecting six-sigma projects:

A qualified outside expert (consultant) who is engaged in introducing, training and supporting the firm’s Six-Sigma projects is of vital value in helping the management select not only the right project, but also the right people to run it.

9. Do be patient at the inception of your six-sigma initiative:

The Six-Sigma projects require the front-end commitment of training, time and resources to achieve the end results. The management and employees have to learn how to select the projects, develop appropriate metrics and assign key roles. These require proper planning.

10. Do claim and advertise easy “wins”:

Even though patience is essential, it is also important to communicate and celebrate each milestone of success in Six-Sigma projects. This is necessary to keep the team’s enthusiasm high and to demonstrate how Six-Sigma is working. The top management, employees, customers and vendors – all need to know the value of the efforts put in by Six-Sigma project teams.

11. Do bench mark:

A bench mark plan that looks at both internal and external performance standards would be helpful to conduct the right gap analysis to know where the firm is and where it should be.

12. Do establish project base lines and goals:

The firm should know its current defect levels, its defect – reduction targets and the savings it wants to achieve. This enables the firm to have the right baselines and goals to measure the progress of its Six-Sigma projects.

13. Do get advance buy – in from your controller:

The leader of the Six Sigma project and the financial controller of the firm must agree on how the real savings are calculated. If they work together, the results can be verified by the controller which further validates the work of Six-Sigma project.

“They Don’t”:

1. Don’t make six-sigma a massive training exercise:

As Six-Sigma focuses on real, tangible financial results (exact, quantifiable cost savings, such as reduced hours, reduced inventory levels etc.), It is important that the leader and the members of Six-Sigma project teams learn how to implement the project and get started. They don’t need extensive training to develop their Six- Sigma skills. They need to know what they are doing, but once they are trained as black belts, they will know exactly how and what they need to do to achieve their goals.

2. Don’t take a “big-bang” approach to six-sigma:

It means, all employees need not be trained at once to be Six-Sigma practitioners. Most organisations can’t manage a lot of changes simultaneously or support hordes of black belts or projects. Therefore, it is vital to have right people to work on right projects, and to train selected people to keep the projects going and capture gains case by case.

3. Don’t focus resources on reworking training material:

Even though training is an important part of Six-Sigma, it is not advisable to spend excessive time in “tweaking” training materials to fit the firm’s exact business model. The training materials should be related to the business focus; recognising the overall and adaptable nature of Six-Sigma.

4. Don’t let the controller waffle about your savings calculations”:

Financial controllers play an important role in the implementation of Six Sigma projects and therefore they must be included right from the beginning of Six-Sigma initiative. They need to know that the company’s executive leadership expects them to cooperate and support the efforts of Six-Sigma project teams. The controller and the Six-Sigma project leader must be in agreement on how the project leader defines and assigns savings to the project.

5. Don’t skip steps:

Skipping necessary steps in Six-Sigma projects to speed up won’t yield the needed information to correct and eliminate the problem in question. Data is vital because Six- Sigma needs quantifiable facts and does not deal with assumptions. Statistical measurements and metrics are applied to analyse the issues so that the project team can prove with data and not by opinion, why and how lasting changes can be made.

6. Don’t be afraid to learn and use statistical tools:

Statistics and statistical tools are essential to Six-Sigma. However, it is not necessary to spend exorbitant amounts of time reviewing statistical data. With the systems and software available, technology and training work together to yield results.

Six Sigma – Benefits

The benefits of six sigma are as below:

1. It enables enhanced product quality.

2. It helps to achieve productivity improvement.

3. It increases customer loyalty to the organization.

4. It helps to have rapid response to changing needs of customers.

5. It helps to eliminate the waste in the organization.

6. Cost is decreased because of wasteful activities.

7. It also increases employee involvement and thus satisfaction and loyalty towards organization.

Six Sigma – Criticisms

Even though Six-Sigma has been known about for quite some time and many firms have gained substantial benefits through implementation of Six-Sigma approach to quality management, still some people have negative views about Six-Sigma and are waiting for a new trend.

Some of the current criticisms for ‘Six-Sigma’ are:

(i) It hinders innovation processes.

(ii) It is best applied to strictly defined projects only.

(iii) It has no relevance for day-to-day operations.

(iv) It is often used as a stand-only methodology, which does not involve the entire organisation.

(v) It only leads to short-term success because it offers quick gains but limited long-term success.

However an international survey comprising respondents who are knowledgeable and experienced with ‘Sig-Sigma’ and quality management revealed that the respondents perceived Six-Sigma to be useful in relation to innovation and long-term developments.

Considering the long-term success of Six-Sigma, top management should take into account the fact that the actual process of any improvement approach adopted by an organisation may be predictable over the first year or so, but will then tend to lose its predictability because of the following reasons-

(i) Organisations will soon begin to change in different ways, as internal opposition to change, as external competitors react and the actions of customers, supplies and corporate office will vary.

(ii) Organisations themselves differ in how they handle these reactions.

A related issue is the extent to which Six-Sigma improvement projects are capable of reaching their stated initial goals/ objectives. All organisation – wide change programmes are expensive in terms of time and money and therefore the consultants or internal activities who initiate such projects need to sell their ideas aggressively to the top management.

But the unpredictability of operating in a competitive environment means that both internal and competitive reactions are difficult to predict and counter. Therefor it is very difficult to demonstrate the effectiveness of the Six-Sigma programmes to justify their adoption.

While some improvement projects are influenced by factors within the control of operators and management, some change goals suffer from lack of any clear relationship between improvement actions and improvements results.

For example improving customer satisfaction or increasing profitability by a certain; amount within a certain specified time may be specific measurable goals, but they can be influenced by many factors that are beyond the ability of employees to influence – from competitive reactions to changes in global economy.